Production process of heavy metal-mediated biochar composites using silicate solidification

A production process and heavy metal technology, applied in the field of heavy metal-mediated biochar production process, to achieve the effects of improving water retention, prolonging migration time, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Put 1 / 2 Hoagland nutrient solution and trace element solution in the incubator, and plant water turtles in the incubator. After one week, add lead nitrate solution with a lead concentration of 260 mg / L in the incubator , the manganese chloride solution with a manganese element concentration of 580 mg / L and the zinc sulfate heptahydrate solution with a zinc element concentration of 420 mg / L simulated polluted water, cultivated for 30 days, and collected the roots, stems and leaves of water turtles after the experiment. It was dried at a temperature of 105 °C for 2 h and crushed to a particle size of 160 μm to obtain heavy metal-based biomass.

[0076] Wherein, the trace element liquid consists of: potassium iodide: 0.83mg / L, boric acid: 6.2mg / L, manganese sulfate: 22.3mg / L, zinc sulfate: 8.6mg / L, sodium molybdate: 0.25mg / L, sulfuric acid Copper: 0.025mg / L, cobalt chloride: 0.025mg / L.

[0077] (2) The heavy metal-based biomass, red mud and bentonite (by dry weight) w...

experiment example 1

[0087] Referring to "Microwave Digestion Method of Total Heavy Metals in Soil (HJ832-2017)", accurately weigh 0.400g of the biochar composite prepared in Example 1 into a polytetrafluoroethylene digestion tank, add 18mL of concentrated nitric acid and 6mL of concentrated HCl , let it stand for 12 hours to react, and then put it into a microwave digestion apparatus for digestion to obtain a digestion solution. After the digestion is completed, transfer the digestion solution to a 250mL volumetric flask, set the volume to the scale line, shake well and pass through a 0.45μm water filter membrane, and use ICP-OES to measure the content of heavy metals lead, manganese and zinc in the filtered solution. As far as the content of heavy metals in the biochar composite is concerned, the total enrichment amount of lead is 18 mg / g, the total amount of manganese enrichment is 112 mg / g, and the total amount of zinc enrichment is 38 mg / g.

experiment example 2

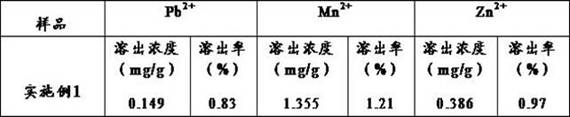

[0089] Referring to the environmental protection standard "Solid Waste Leaching and Toxicity Leaching Method (HJ 557-2009)", weigh 0.4g of the biochar compound of Example 1 into a 500m conical flask, add 200mL of deionized water, and seal the bottle with a parafilm Place the Erlenmeyer flask in a constant temperature shaking box and shake it for 8 hours at 25°C with a frequency of 110 times / min. Water-based filter membrane, the content of Pb, Mn and Zn elements in the filtrate was measured by ICP-OES, and the obtained results are shown in Table 1:

[0090] Table 1: Content and dissolution rate of heavy metals in biochar composites

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com