A self-cleaning safety separator, an integrated separation and cleaning system using the separator, and a method for using the system

A safe and separator technology, applied in the field of oil drilling, can solve the problems affecting normal operation, no liquid in the outlet pipe, long cleaning time, etc., and achieve the effect of sedimentation and separation, ingenious and reasonable structure, and rapid cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

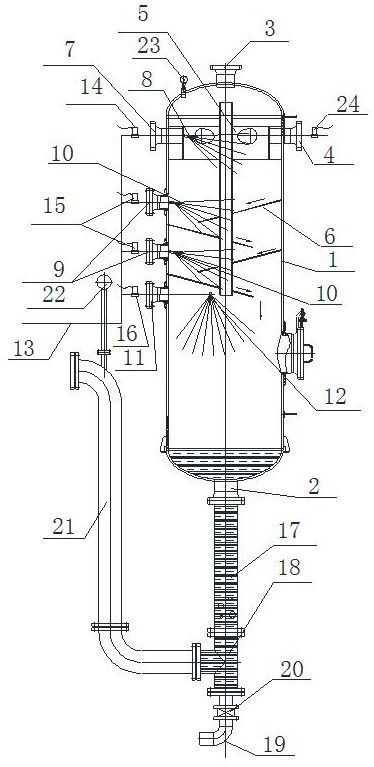

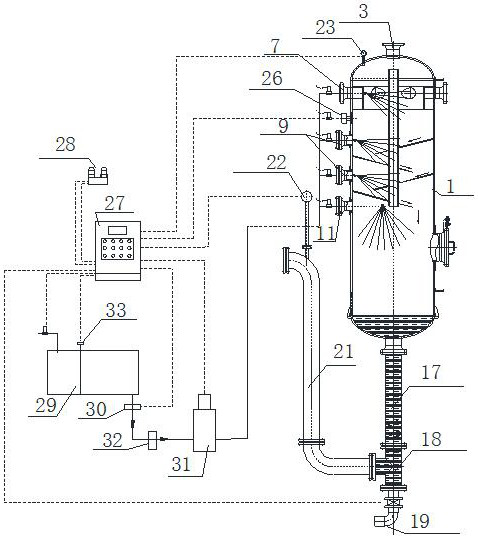

[0042] A self-cleaning safety type separator belongs to the technical field of oil drilling, reference figure 1 , including a tank body 1, the lower part of the tank body 1 is connected with a discharge port 2; the upper part is connected with an exhaust pipe 3 and a fluid input pipe 4, a separation mechanism 5 is fixed above the inside of the tank body 1, and the bottom of the separation mechanism 5 inside the tank body 1 is staggered A deflector 6 is provided, and a cleaning hole I7 is provided on the wall of the tank body 1 flush with the separation mechanism 5, and a high-pressure nozzle I8 is installed at one end of the cleaning hole I7 in the tank body 1, and each guide A cleaning hole II9 is provided on the wall of the tank body 1 above the flow plate 6, and a high-pressure nozzle II10 is installed at one end of the cleaning hole II9 in the tank body 1, and on the inner wall of the tank body 1 below the flow guide plate 6 at the bottom end A cleaning hole III11 is ope...

Embodiment 2

[0047] This embodiment is a further improvement on Embodiment 1, the difference is that the inclination of the deflectors 6 is 15°, and the distance between adjacent deflectors 6 is 100 cm.

Embodiment 3

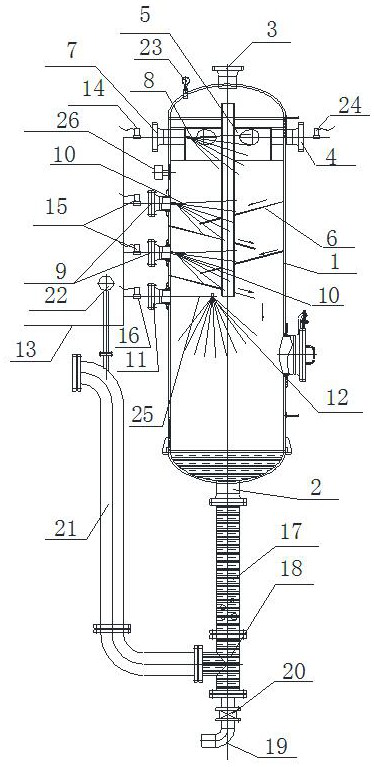

[0049] Compared with Embodiments 1 and 2, this embodiment differs in that, with reference to Figure 4 , the nozzle direction of the high-pressure nozzle II10 is consistent with the inclination direction of the deflector 6 .

[0050] The high-pressure nozzle I8 and the high-pressure nozzle II10 in this embodiment use solid cone nozzles, and the annular high-pressure nozzle 12 uses multi-head combination nozzles. During installation, contact with drilling fluid should be avoided as much as possible, which will affect normal use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com