Centrifugal regulator test bed

A regulator and centrifugal technology, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of affecting service life, high working noise, and high price, so as to avoid equipment damage, Stable performance and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

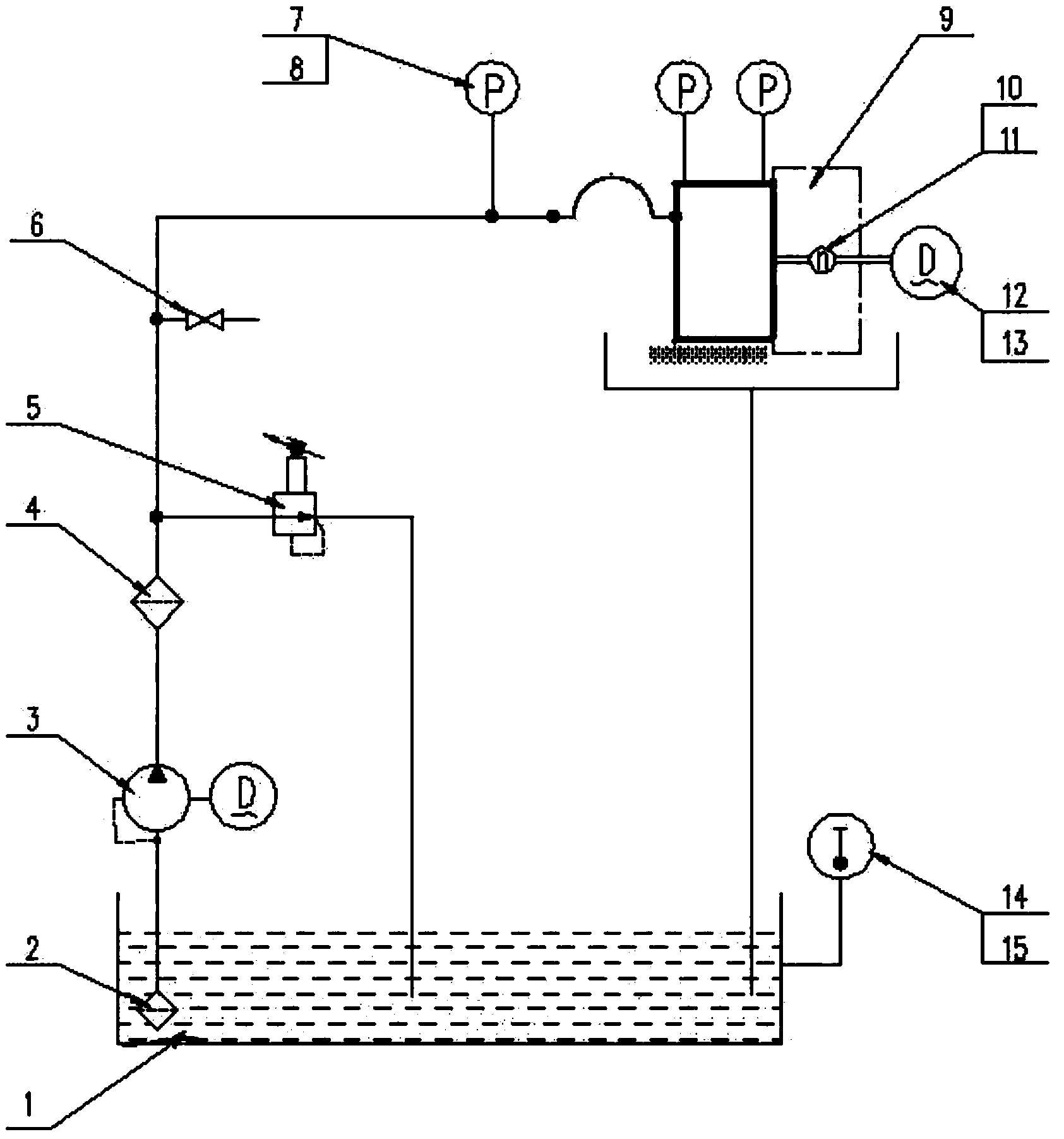

[0023] This embodiment provides a centrifugal regulator test bench, the structure is as follows figure 1 As shown, it includes lower oil tank 1, oil suction port filter 2, vane oil pump 3, hydraulic oil filter 4, proportional overflow valve 5, pressure sensor 7, pressure measuring and controlling instrument 8, regulator test tooling 9, magnetoelectric speed sensor 10 , speed digital display 11, frequency conversion speed regulating motor 12 and frequency converter 13, the oil suction port filter 2 is placed below the working liquid level in the lower oil tank 1, and is connected to the vane type oil pump 3 through the hydraulic pipeline, and the vane type oil pump 3 passes through the hydraulic pressure The pipeline is connected to one end of the hydraulic oil filter 4, and the other end is connected to the oil inlet of the regulator to be tested through the hydraulic pipeline;

[0024] The regulator test tool 9 is installed in the oil collection tank. The regulator test tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com