Ultrasonic welding construction method for small-caliber PE natural gas pipeline

A natural gas pipeline, ultrasonic welding technology, applied in the direction of pipeline connection layout, pipes/pipe joints/pipe fittings, tubular objects, etc., can solve the problems of complex operation process and welding technology, inoperable operation mode, low operation efficiency, etc., to achieve The effect of extending the construction operation season, reducing the requirement for technical proficiency, and increasing the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0042] The ultrasonic welding construction method of the small-caliber PE natural gas pipeline of the present invention comprises the following steps:

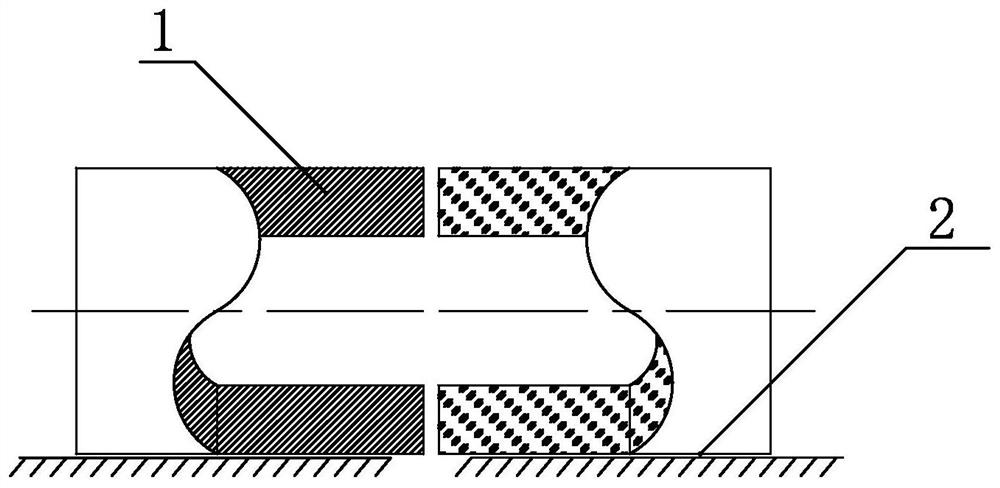

[0043] S10, cleaning the upper PE natural gas pipeline 11 and the lower PE natural gas pipeline 18, chamfering, and removing surface scale;

[0044] S20, installing the upper PE natural gas pipeline 11 and the lower PE natural gas pipeline 18 in the upper clamping welding device and the lower clamping welding device respectively, and clamping the pipelines by the clamping welding device;

[0045] S30, fixing the positions of the upper clamping welding device and the lower clamping welding device;

[0046] S40, setting the upper fixing block 16 and the lower fixing block 19 to respectively fix the upper PE natural gas pipeline 11 and the lower PE natural gas pipeline 18;

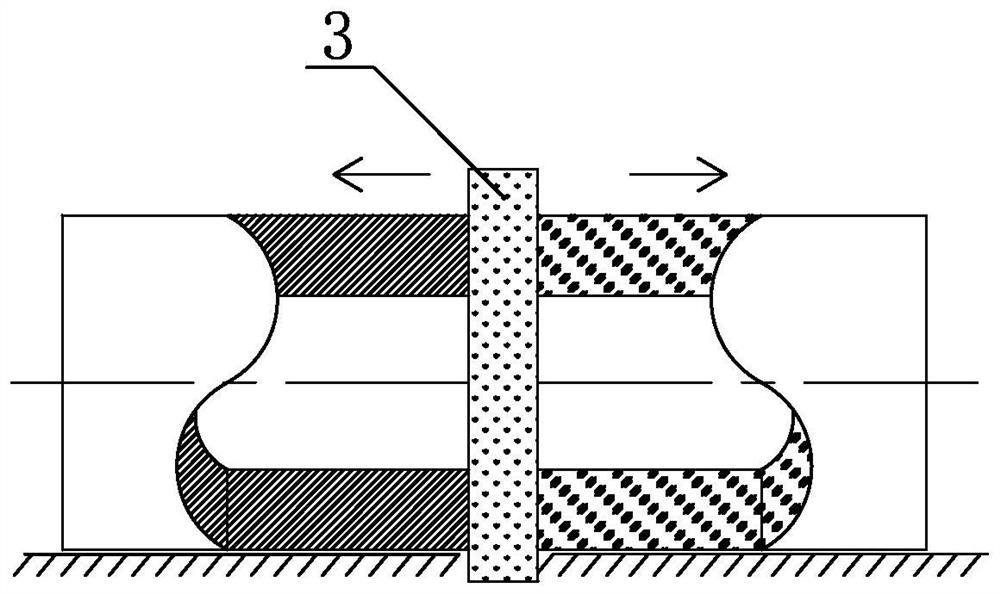

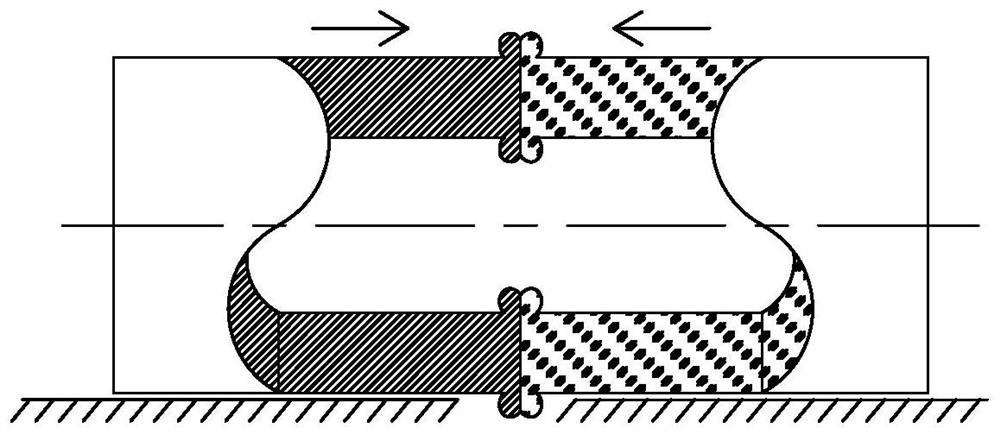

[0047]S50, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com