Glass cleaning solution, and preparation method and application thereof

A glass cleaning and cleaning solution technology, which is applied to cleaning methods and utensils, cleaning methods using liquids, and preparation of detergent mixture compositions. Difficult to occupy dust, reduce surface tension, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0050] According to a preferred embodiment of the present invention, the method also includes mixing water with alcohol, sodium metasilicate and / or lithium metasilicate, and surfactants in sequence, and the surfactants include zwitterionic surfactants One or more of surfactants, nonionic surfactants, anionic surfactants and low foaming surfactants.

[0051] According to another preferred embodiment of the present invention, the method also includes mixing water with alcohol, sodium metasilicate and / or lithium metasilicate, corrosion inhibitor and surfactant in sequence, and the surfactant Including one or more of zwitterionic surfactants, nonionic surfactants, anionic surfactants and low-foaming surfactants.

[0052] According to the present invention, preferably, in order to avoid turbidity in the process of preparing the solution, the method comprises: taking 100 kg of windshield cleaning solution as an example, dissolving 0.02 kg of sodium metasilicate in advance with 10 kg...

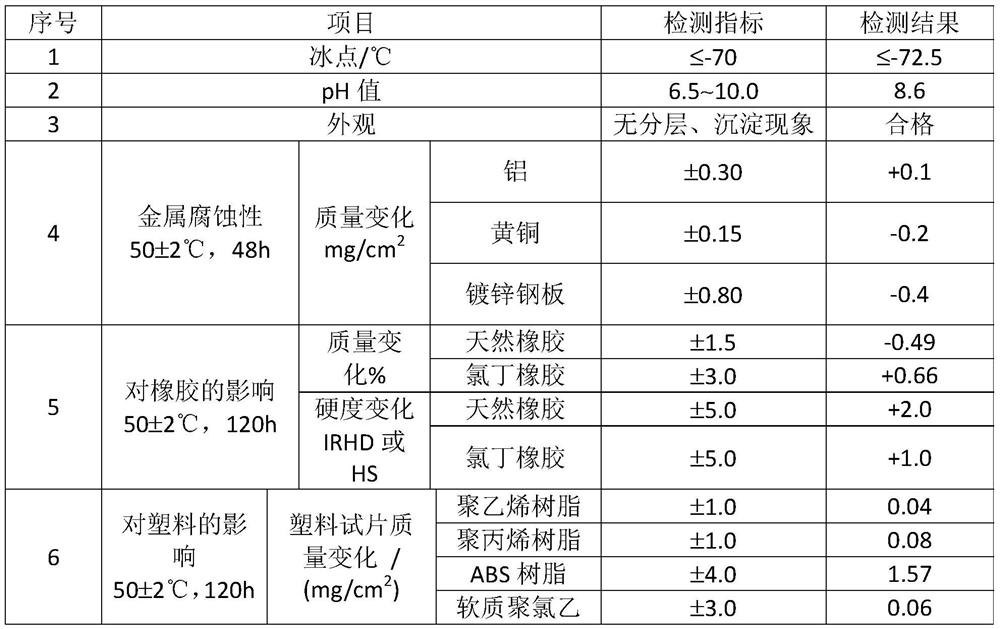

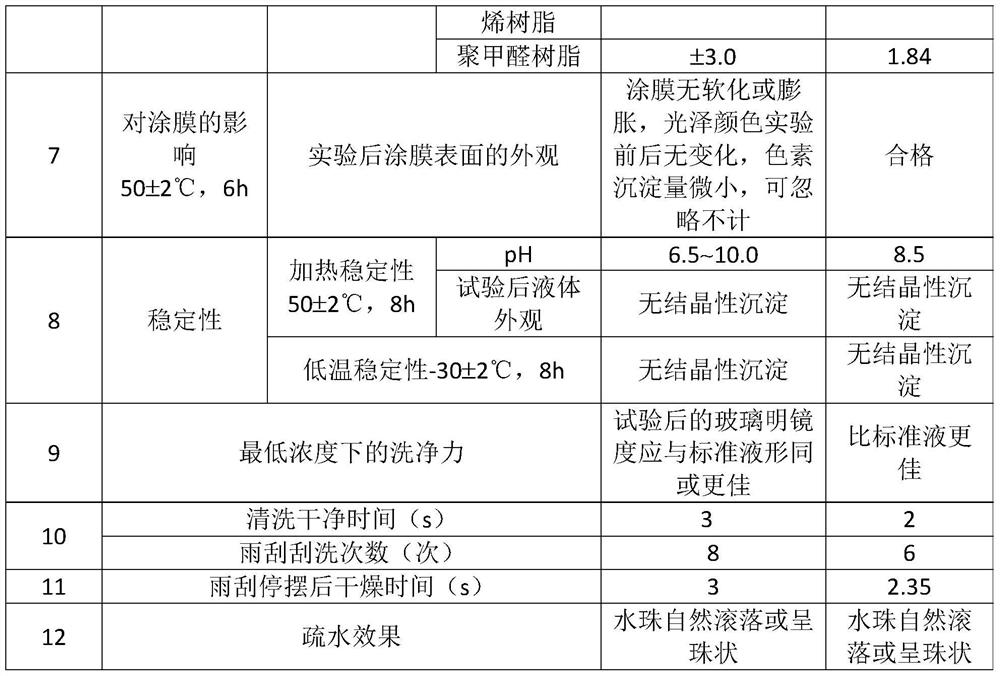

Embodiment 1

[0063] This embodiment is to illustrate the glass cleaning solution of the present invention.

[0064] (1) Take the 100kg windshield cleaning solution as an example, dissolve 0.02kg of sodium metasilicate in advance with 10kg of water, and prepare an aqueous solution of sodium metasilicate for subsequent use;

[0065] (2) Combine deionized water with sodium metasilicate aqueous solution, methanol, corrosion inhibitor (tolyltriazole) and surfactants (cocamidopropyl betaine, perfluorooctyl polyoxyethylene ether) in sequence and isotridecanyl polyoxyethylene ether phosphate), wherein, based on the total weight of the prepared glass cleaning solution, the composition of deionized water, methanol, corrosion inhibitor, sodium metasilicate and surfactant Part and component content are as shown in table 2 (by weight percentage);

[0066] (3) After passing the test, filter and fill through a 0.1-0.5 μm filter.

[0067] Table 2

[0068] components content(%) Specificati...

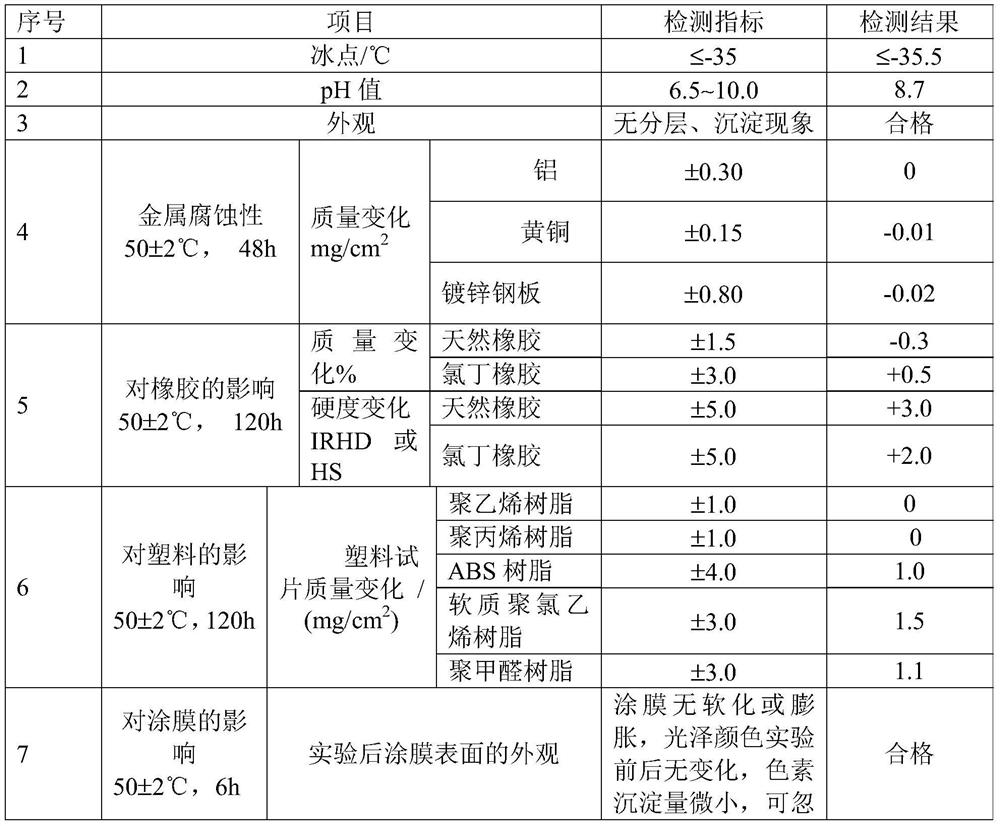

Embodiment 2

[0074] This example

[0075] This is to describe the glass cleaning solution of the present invention.

[0076] (1) Take the 100kg windshield cleaning solution as an example, dissolve 0.02kg of sodium metasilicate in advance with 10kg of water, and prepare an aqueous solution of sodium metasilicate for subsequent use;

[0077] (2) Combine deionized water with sodium metasilicate aqueous solution, ethanol, corrosion inhibitor (tolyltriazole) and surfactant (perfluorooctyl polysiloxane, cocamidopropyl beet) in sequence Alkali, isooctyl alcohol polyoxyethylene ether phosphate and octoxynyl ether phosphate) are mixed evenly, wherein, based on the total weight of the prepared glass cleaning solution, deionized water, alcohol, corrosion inhibitor, metasilicate Component and component content of sodium and tensio-active agent are as shown in table 4 (by weight percentage);

[0078] (3) After passing the test, filter and fill through a 0.1-0.5 μm filter.

[0079] Table 4

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com