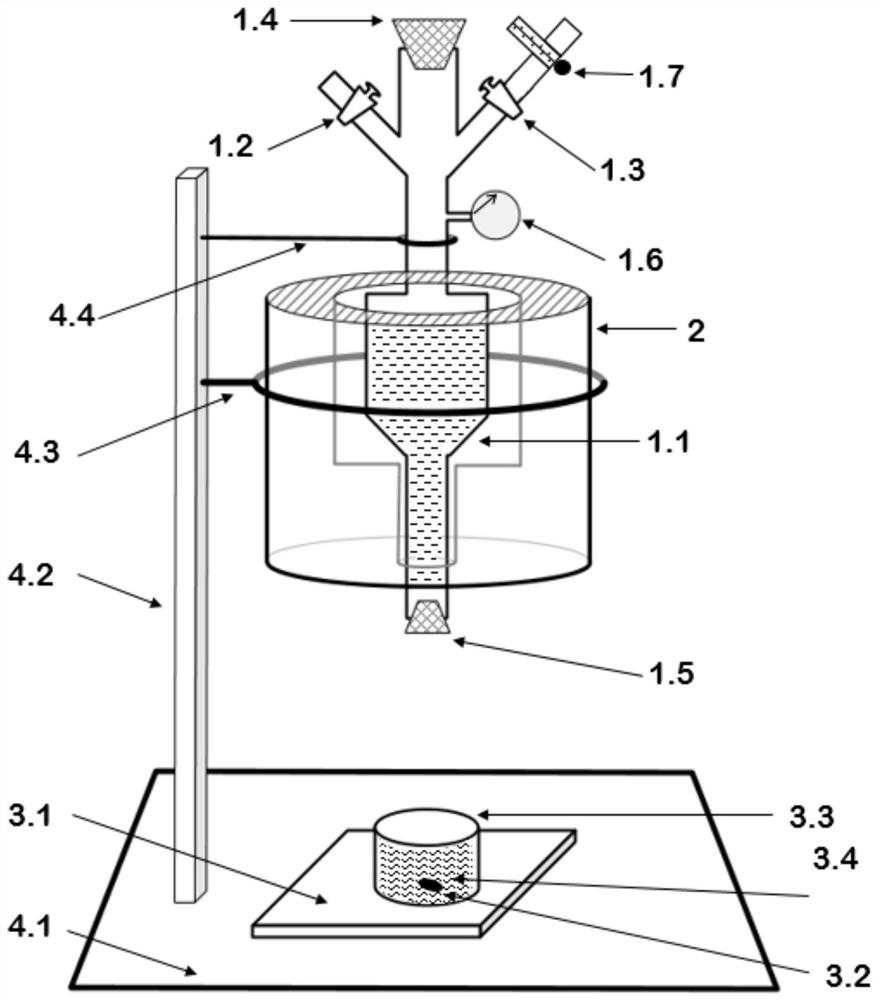

Preparation device of chalcogenide glass ball blank, and using method thereof

A technology of chalcogenide glass and preparation equipment, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of low material utilization rate, achieve the effects of short processing time, avoid sudden cooling cracking, and avoid oxidation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

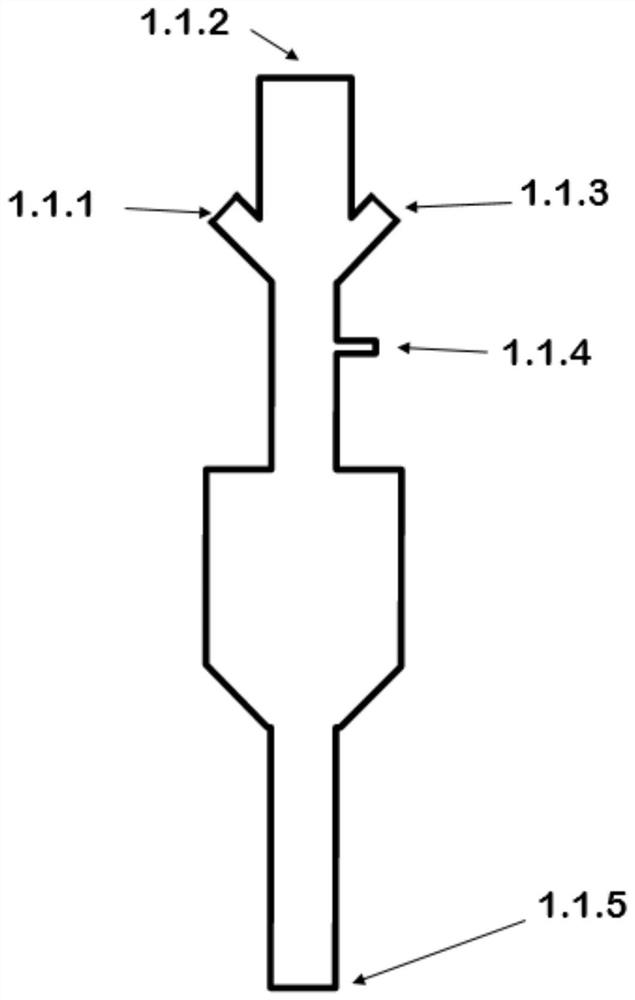

[0066] Example 1: 3mm diameter As 2 Se 3 Preparation of Chalcogenide Glass Spheroids.

[0067] In this embodiment, As 2 Se 3 Chalcogenide glass, the glass transition temperature is 185°C, and the inner diameter of the crucible outlet is 2mm. The barometer displays the relative air pressure. When the air pressure indication is zero, it means the ambient atmospheric pressure; when the barometer (1.6) shows a negative number, it means it is less than the ambient atmospheric pressure; ambient atmospheric pressure.

[0068] The ball blank preparation method comprises the following steps:

[0069] (1) Seal the discharge port with a discharge plug, and then As 2 Se 3 Put the chalcogenide glass block material into the quartz crucible through the feed port, and then use the feed plug to seal the feed port; (2) close the inlet valve, open the exhaust valve, and pump the quartz crucible until the air pressure is expressed as -10kPa, then close the pumping valve, then open the int...

Embodiment 2

[0070] Example 2: Ge with a diameter of 10mm 10 As 40 Se 50 Preparation of Chalcogenide Glass Spheroids.

[0071] In this embodiment, the Ge produced by China Academy of Building Materials Research Co., Ltd. is selected. 10 As 40 Se 50 Chalcogenide glass, the glass transition temperature is 225°C, and the inner diameter of the crucible outlet is 6.8mm. The barometer displays the relative air pressure. When the air pressure indication is zero, it means the ambient atmospheric pressure; when the barometer (1.6) shows a negative number, it means it is less than the ambient atmospheric pressure; ambient atmospheric pressure.

[0072] The ball blank preparation method comprises the following steps:

[0073] (1) Seal the discharge port with a discharge plug, and then place Ge 10 As 40 Se 50 Put the chalcogenide glass block material into the quartz crucible through the feed port, and then use the feed plug to seal the feed port; (2) close the inlet valve, open the exhaust v...

Embodiment 3

[0074] Example 3: Ge with a diameter of 20mm 28 Sb 12 Se 60 Preparation of Chalcogenide Glass Spheroids.

[0075] In this embodiment, the Ge produced by Hubei New Huaguang Information Materials Co., Ltd. 28 Sb 12 Se 60 Chalcogenide glass, the glass transition temperature is 285°C, and the diameter of the outlet of the crucible is 13mm. The barometer displays the relative air pressure. When the barometric pressure is zero, it means the ambient atmospheric pressure. When the barometer (1.6) shows a negative number, it means it is less than the ambient atmospheric pressure; when the barometer (1.6) shows a positive number, it means it is greater than ambient atmospheric pressure.

[0076] The ball blank preparation method comprises the following steps:

[0077] (1) Seal the discharge port with a discharge plug, and then place Ge 28 Sb 12 Se 60 Put the chalcogenide glass block material into the quartz crucible through the feed port, and then use the feed plug to seal the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com