Method of injecting ammonia fuel into a reciprocating engine

A technology of fuel injection and fuel injector, which is applied in combustion engine, fuel injection control, internal combustion piston engine, etc. It can solve the problems of reducing supercharging cooling, high NOx, slow combustion, etc., and achieve the effect of improving ammonia ignition and combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

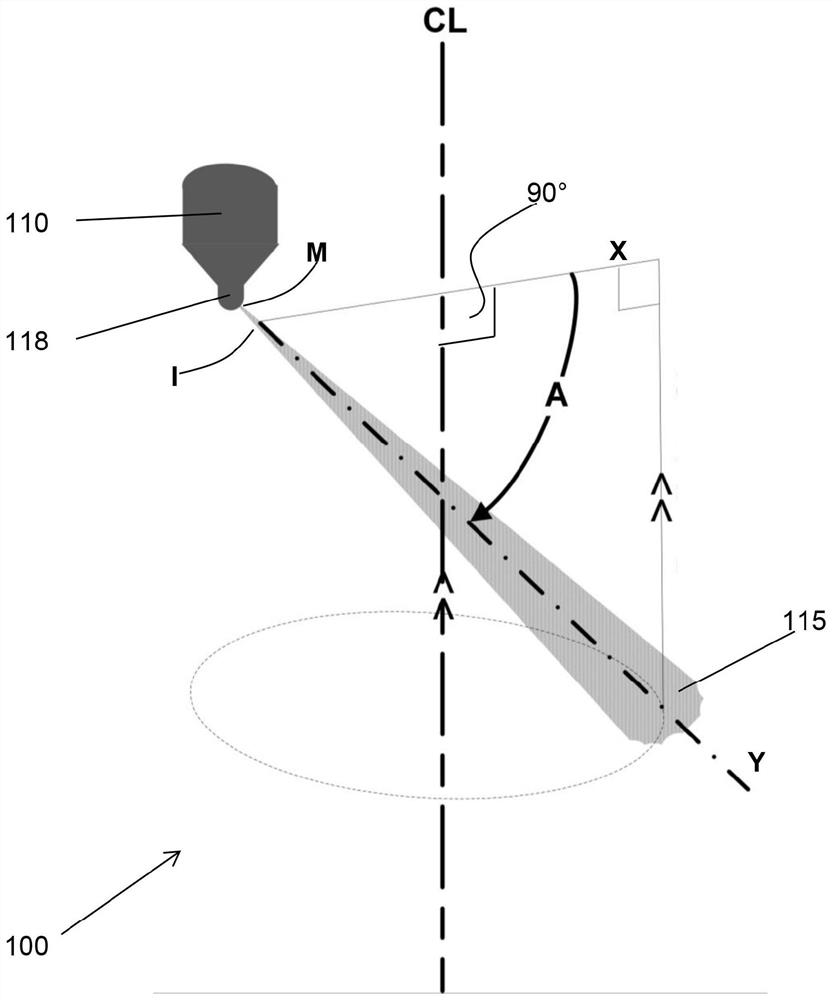

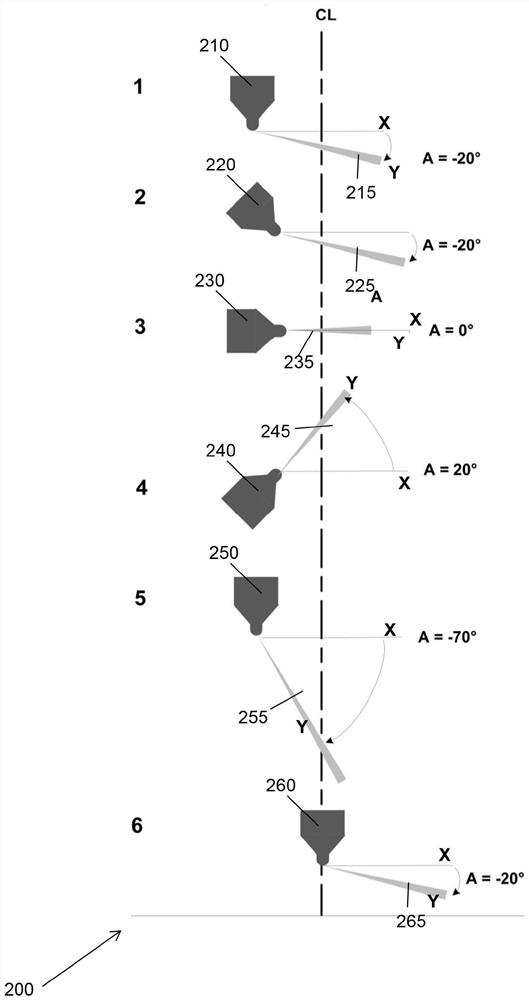

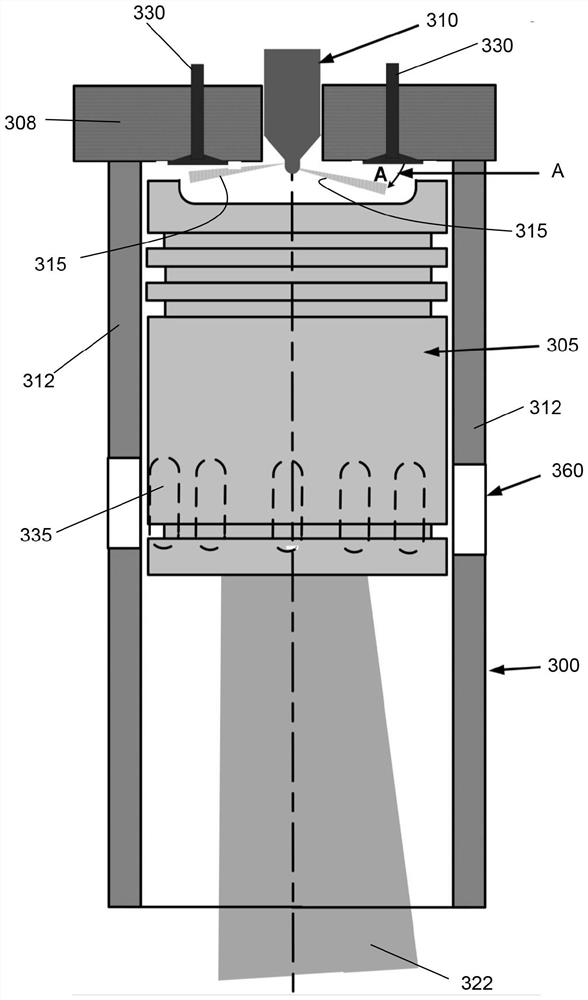

[0062] The method of the invention can be advantageously used in low, medium and high speed engines, trunk piston and crosshead engines, 2-stroke cycle engines and 4-stroke cycle engines, and spark, plasma or laser ignition engines. The invention is particularly applicable to conventional trunk piston 2-stroke engines, as well as to low speed crosshead engines, such as those used in deep water vessels. The specific implementation manner of the first aspect of the present invention is as follows:

[0063] For top-injected (injector located in the cylinder head) trunk-piston, single-flow, 2-stroke engines, the method of the first aspect of the invention comprises injecting ammonia fuel as at least one fuel jet as one or more fuel jets to Angles A of -90° and -35° were injected into the combustion chamber of each cylinder with ammonia fuel injection timed to occur after the exhaust valve closed and before 45 degrees of the crank at top dead center.

[0064] For a top injection (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com