PCB enterprise order management system and method

A technology for order management and PCB boards, applied in manufacturing computing systems, data processing applications, collaborative operation devices, etc., can solve problems such as inaccurate scanning, affecting scanning speed, unclear production site bottleneck procedures, etc., and achieve workflow specifications , improve production efficiency, and facilitate the traceability of quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

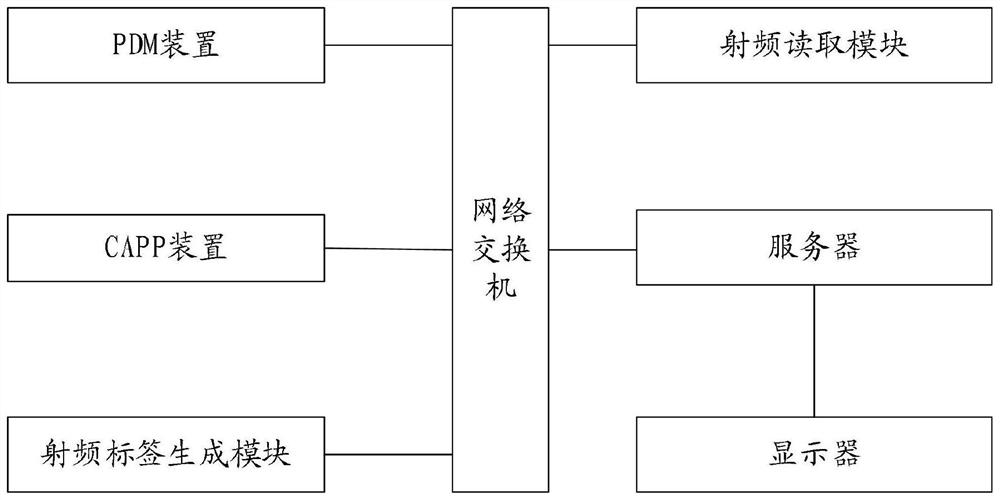

[0029] See attached figure 1 As shown, Embodiment 1 of the present invention discloses a PCB enterprise order management system, including: PDM device, CAPP device, radio frequency tag generation module, radio frequency reading module, network switch, server and display, PDM device, CAPP device and radio frequency The label generating module is connected to the network switch through communication, the network switch is connected to the radio frequency reading module and the server, and the server is connected to the display.

[0030] In a specific embodiment, the number of the radio frequency tag generation module is one or any number, and is set on the production equipment or production line.

Embodiment 2

[0032] On the other hand, Embodiment 2 of the present invention provides a PCB enterprise order management method, comprising the following steps:

[0033] S100: Obtain PCB board order data, and use the PDM device to define PCB board manufacturing information according to the PCB board order data;

[0034] S200: Using the CAPP device to automatically generate a corresponding process flow and product ID according to the manufacturing information of the PCB board;

[0035] S300: Generate the content of the radio frequency tag through the radio frequency tag generation module according to the process flow of the PCB board and the product ID, and attach it to the corresponding PCB board;

[0036] S400: Read the attached radio frequency tag information of the PCB board through the radio frequency reading module during the execution of each step of the process flow.

[0037] Specifically, the PDM device defines the manufacturing information of the PCB board according to the PCB boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com