Preparation method of WO3 gas-sensitive material, prepared gas-sensitive material and application of gas-sensitive material

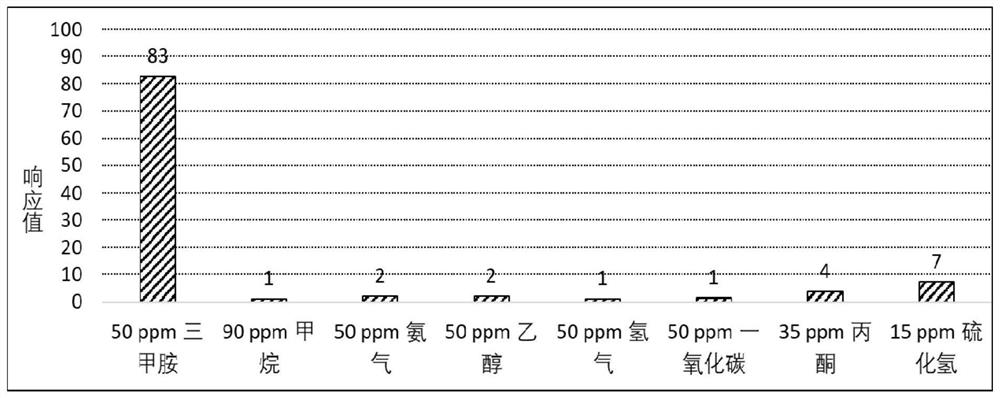

A gas-sensitive material and reaction system technology, which is applied in material resistance, material analysis, material analysis by electromagnetic means, etc., can solve problems such as difficulty, and achieve simple preparation methods, easy miniaturization, good response and selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Based on WO 3 The preparation method of the MEMS gas sensor of gas sensitive material, comprises the following steps:

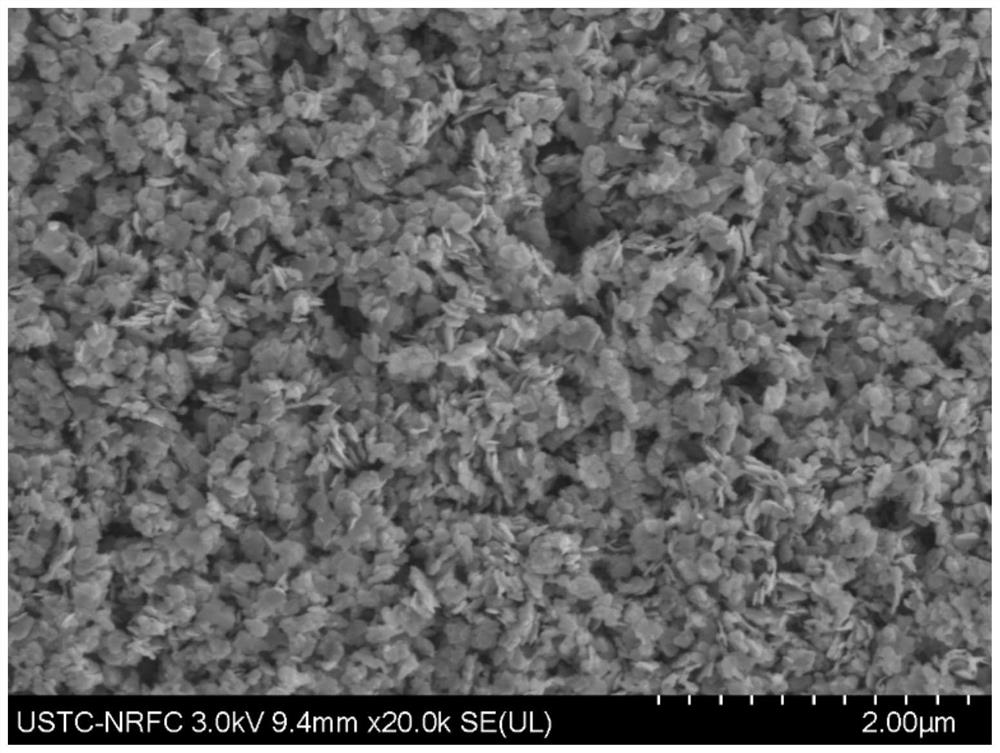

[0065] (1) Preparation of WO 3 Gas sensitive material: 3g Na 2 WO 4 2H 2 O was dissolved in 20ml of water, and under the condition of stirring, sulfuric acid with a concentration of 6mol / L was added dropwise to adjust the H of the solution. + The concentration value is 2.4mol / L, stirred for 2h, kept at 30°C for 24h, washed the obtained precipitate with water and ethanol alternately, dried at 80°C for 12h, and then heat-treated at 300°C for 2h to obtain WO 3 gas sensitive material. where H + The determination method of the concentration is a prior art, and will not be described in detail in this embodiment.

[0066] (2) Based on WO 3 Preparation of MEMS sensitive chip of gas sensitive material: the WO 3 After the gas-sensitive material is mixed with a solvent, it is ball-milled to make a uniform slurry, where the solvent includes but not limite...

Embodiment 2

[0069] Based on WO 3 The preparation method of the MEMS gas sensor of gas sensitive material, comprises the following steps:

[0070] (1) Preparation of WO 3 Gas sensitive material: 3g Na 2 WO 4 2H 2 O was dissolved in 20ml of water, and under the condition of stirring, sulfuric acid with a concentration of 6mol / L was added dropwise to adjust the H of the solution. + The concentration value is 2.4mol / L, stirred for 2h, kept at 30°C for 24h, washed the obtained precipitate with water and ethanol alternately by centrifugation, dried at 80°C for 12h, and heat-treated at 500°C for 2h to obtain WO 3 gas sensitive material. where H + The determination method of the concentration is a prior art, and will not be described in detail in this embodiment.

[0071] (2) Based on WO 3 Preparation of MEMS sensitive chip of gas sensitive material: the WO 3 After the gas-sensitive material is mixed with a solvent, it is ball-milled to make a uniform slurry, where the solvent includes b...

Embodiment 3

[0074] Based on WO 3 The preparation method of the MEMS gas sensor of gas sensitive material, comprises the following steps:

[0075] (1) Preparation of WO 3 Gas sensitive material: 0.5g Na 2 WO 4 2H 2 O and 0.3 g of citric acid were dissolved in 30 ml of water, and after stirring for 30 min, under stirring conditions, 6 mol / L of hydrochloric acid was added dropwise to adjust the H of the solution. + The concentration is 0.1mol / L. After stirring for 60 minutes, the mixed solution was transferred to a 50ml reaction kettle, put into a drying oven, and reacted at 200°C for 12 hours. After the hydrothermal reaction, the precipitate was alternately centrifuged with water and ethanol, dried at 80°C for 4h, and heat-treated at 450°C for 1h to obtain WO 3 gas sensitive material. where H + The determination method of the concentration is a prior art, and will not be described in detail in this embodiment.

[0076] (2) Based on WO 3 Preparation of MEMS sensitive chip of gas se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com