Method for determining macroscopic modulus of shale through fine/micro mechanical test

A micromechanics and shale technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and testing material hardness, etc., can solve the problems that the continuum theory cannot accurately express the mechanical properties of multiphase media, and achieve reduction The effect of test cost and shortened test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

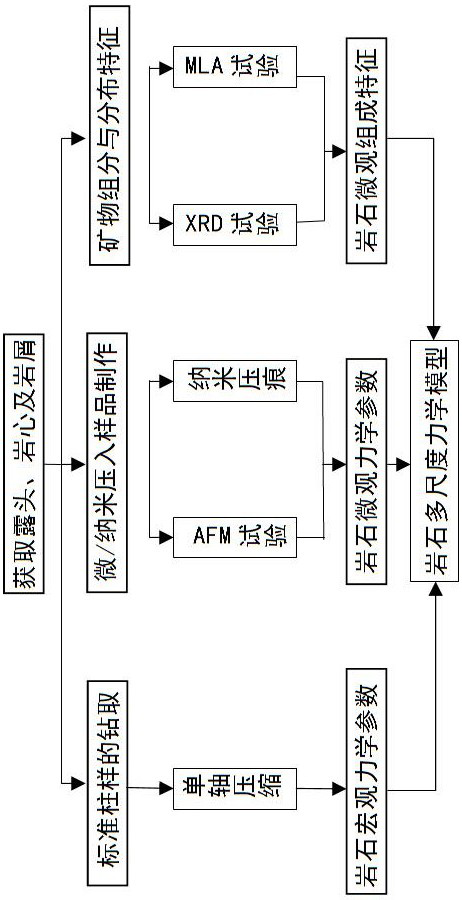

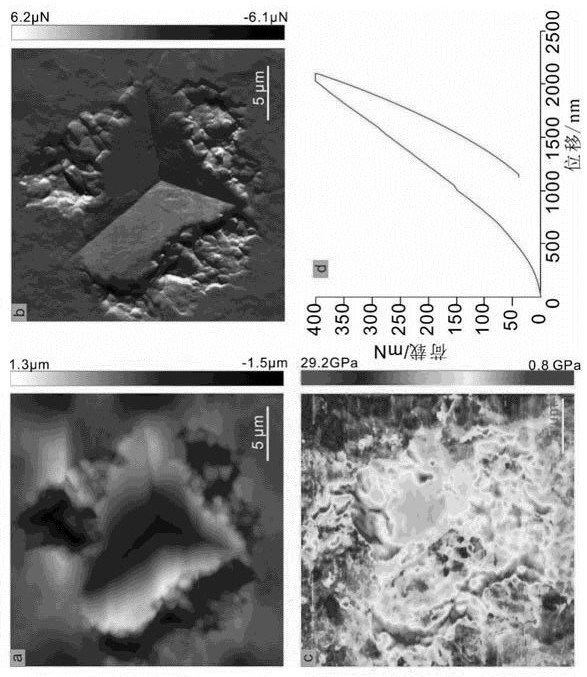

[0042] Such as Figure 1-Figure 5 As shown, a method of determining the macroscopic modulus of shale by micro / micromechanical testing of the present invention comprises the following steps:

[0043] (1) Drill standard rock sample a and sample b in two directions parallel to the bedding and perpendicular to the bedding respectively, measure and record the diameter and height of sample a and sample b collected;

[0044] (2) Perform uniaxial compression tests on sample a and sample b to obtain Young's modulus and Poisson's ratio on the macro scale;

[0045] (3) Cut the sample a and sample b after the uniaxial compression test into four 20mm×10mm×5mm slices, these four slices are respectively, a V , b V 、a P and b P , where a V and b V The slice direction is parallel to the bedding, a P and b P The slice direction is perpendicular to the bedding;

[0046] (4) taking the residual sample after cutting sample a and sample b in step (3) and performing X-ray diffraction to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com