Tension-compression and fatigue loading testing machine based on laser confocal microscope

A laser confocal and fatigue loading technology, applied in the direction of applying stable tension/pressure to test the strength of materials, using optical devices, measuring devices, etc., can solve the problems of small observation range, complicated operation process, loss of test piece information, etc. Achieve the effect of improving precision and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

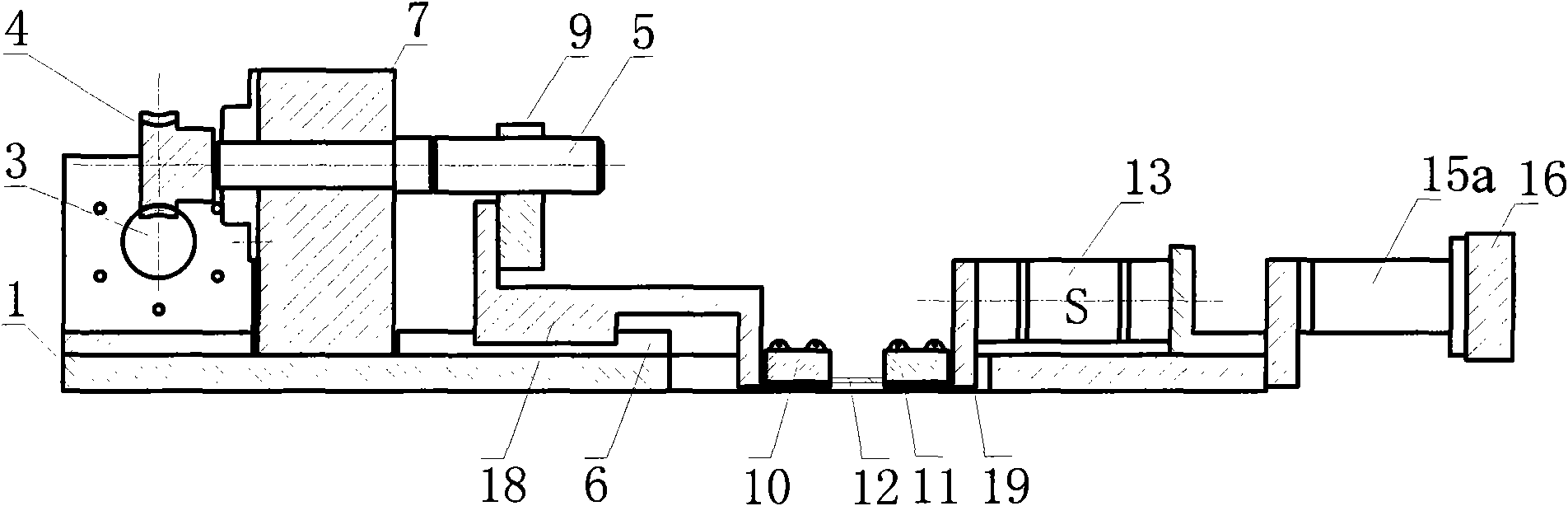

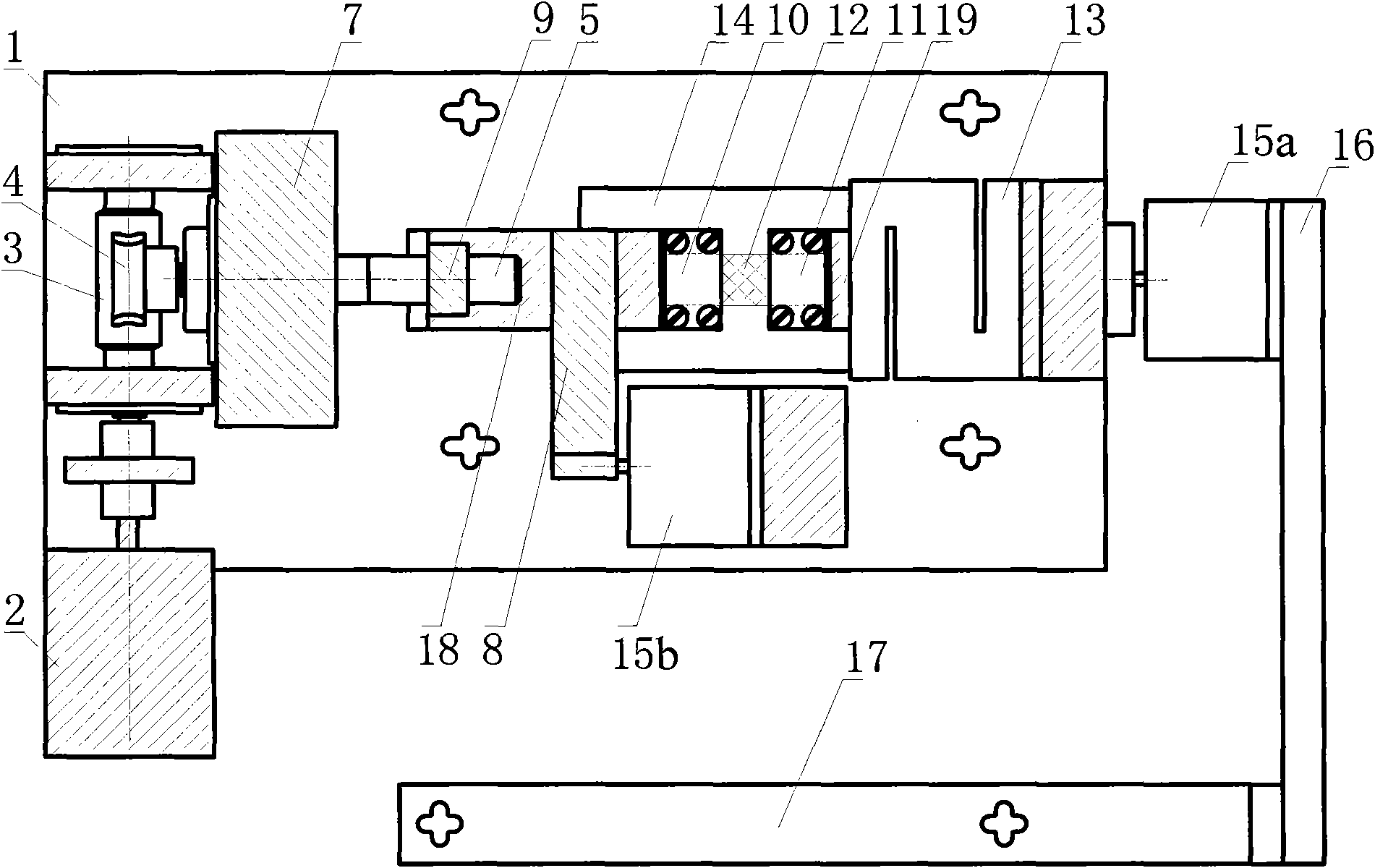

[0036] Measuring the deformation of metal specimens under tensile loading using the phase-shift moiré method

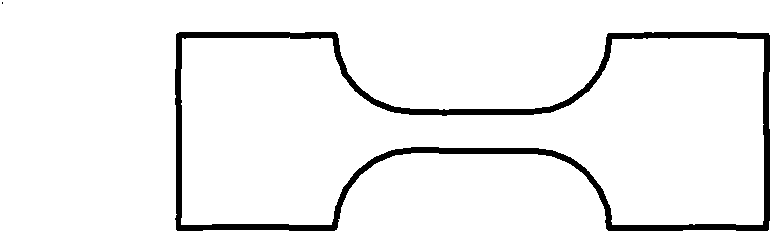

[0037] Make a typical metal test piece, its shape is as image 3 As shown, it can also be slightly changed according to needs. Paste a holographic orthogonal grating with 1200 lines / mm on the surface of the metal test piece, put it into the two holders of the loading device, and tighten the screws on the holder to fix the test piece. The nut 9 is disconnected from the slider 19, and the first piezoelectric ceramic 15a is placed. Then use the stepper motor controller to control the stepper motor 2 to load, read out the force load result with the force load display of the force sensor 13, load in sections, and collect images at the end of each loading. When collecting images, it is necessary to set the scanning line width of the laser scanning confocal microscope to about 0.833um, which is close to the grating pitch of 1200 lines / mm. Moire streaks will be produced. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com