Drying device and drying method

A drying device and desiccant technology, which is applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., can solve the problems of large shape, occupying a large space, and difficulty in taking and placing the drying device, and achieve light weight , saving space and low logistics cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

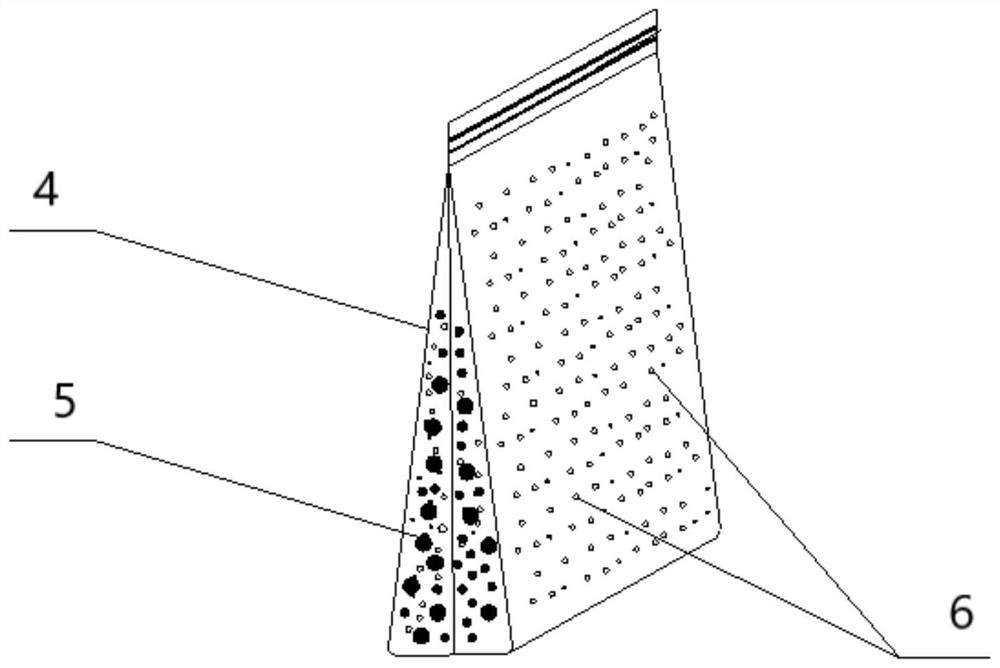

[0041] As an embodiment of the embodiment of the present invention, the synthetic fibers include, but are not limited to, any of the following: polyester, nylon.

[0042] As an embodiment of the embodiment of the present invention, the above-described sealing housing 1 may further include a support layer made of a aluminized film, the support layer disposed on the inner surface of the first flexible layer, the support layer The thickness can be 0.05-0.15mm.

[0043] The aluminizing film is well supported, and the self-supporting properties of the sealing housing 1 can be further improved, and the problem of collapse of the sealing housing 1 collapsed by the first flexible layer is reduced by the first flexible layer. The thickness of the aluminum plating film is too thin, the self-supporting performance is limited, the thickness of the aluminized film is too thick, the flexibility of the sealing housing 1 is deteriorated, and the folding performance is not good, affecting the shap...

Embodiment 1

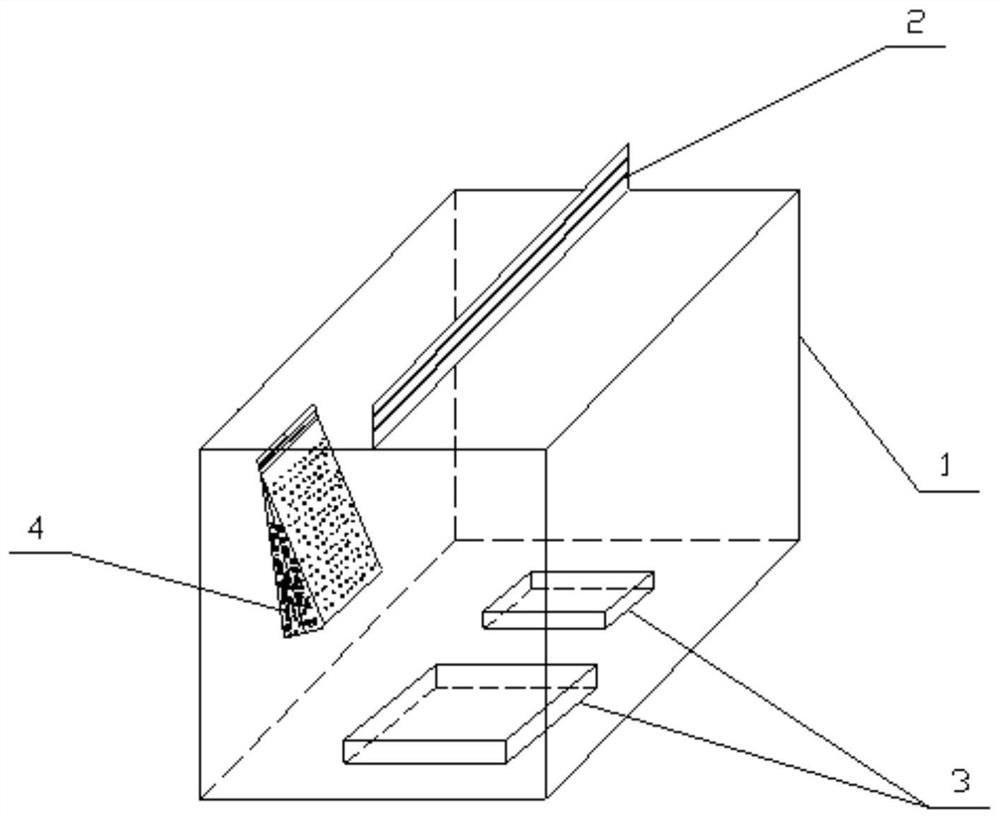

[0060] Example 1 provides a drying device, combined figure 1 The drying apparatus includes a sealing housing 1, a desiccant flushing package 4, and 2 samples 3, wherein the sealing housing 1 is a rectangular parallelepiped, a first flexible layer made of polyethylene, a first flexible layer The thickness is 1.2mm, and a pressureable sealing port 2 is provided on the top surface of the first flexible layer; the desiccant mask 4 is pasted on the side wall of the sealing housing 1 by the rubber; 2 samples 3 paste The bottom surface is fixed to the inside of the sealing housing 1.

Embodiment 2

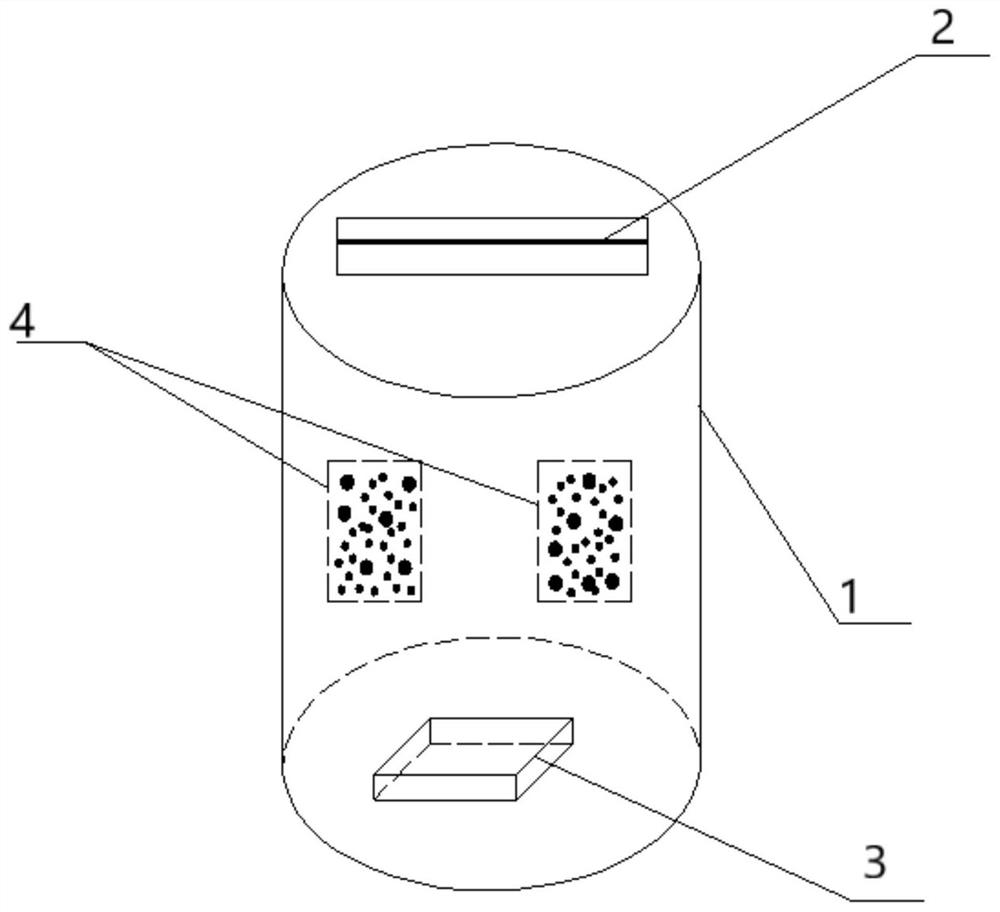

[0062] Example 2 provides a drying device, a combination figure 2 The drying apparatus includes a sealing housing 1, a desiccant proscence package 4, and a sample 3, wherein the sealing housing 1 is cylindrical, and the sealing housing 1 is made of a first flexible layer made of polycarbonate and The second flexible layer made of polyester, the first flexible layer is the inner layer of the sealing housing 1, the thickness is 1.5 mm; the second flexible layer is the outer layer of the sealing housing, the thickness is 0.2mm, the first flexible layer and The second flexible layer is composite through the glue. The top surface of the first flexible layer and the second flexible layer is provided on the top surface of the sealing port 2; the desiccant flush 4 is attached to the side wall of the first flexible layer; 1 sample The torch is attached to the inner bottom surface of the first flexible layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com