Double-turbulent-flow combined oil flinger

An oil throwing tray and combined technology, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as insufficient oil throwing volume, poor atomization effect, small fuel atomization cone angle, etc. Good temperature field distribution, good atomization effect, and improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

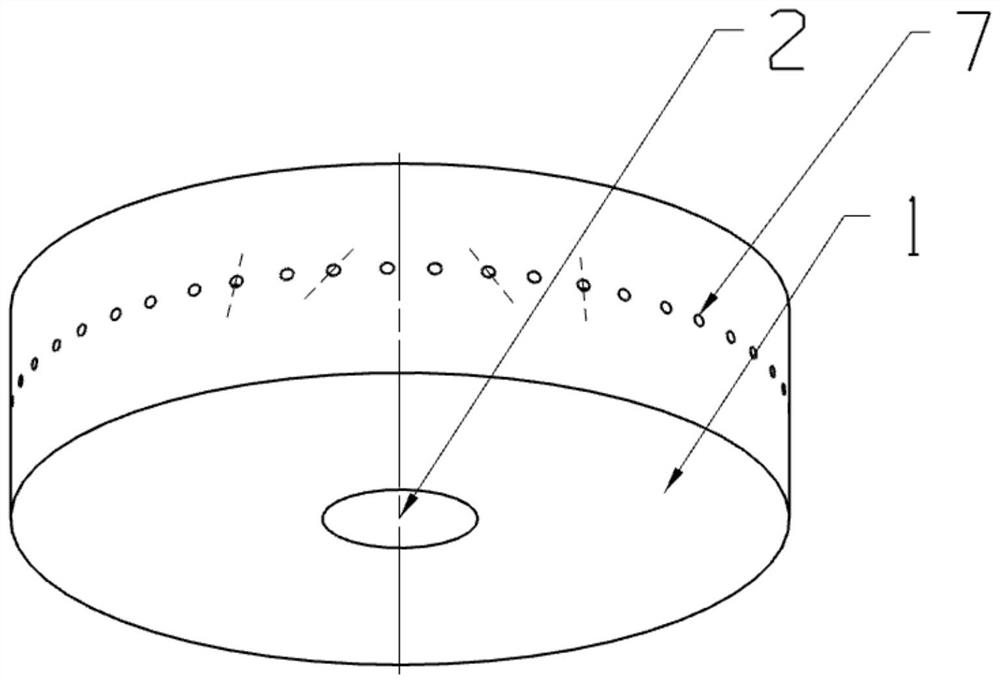

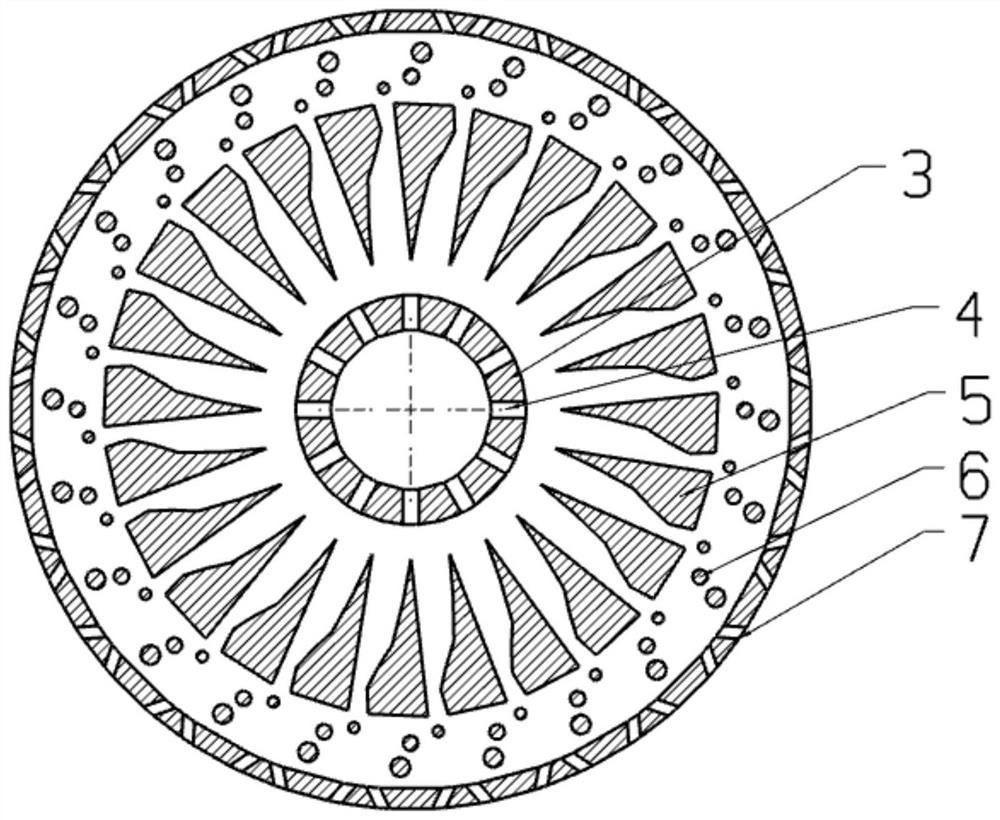

[0021] combine figure 1 , figure 2 , the present invention is a double turbulence combined oil flinger.

[0022] When it works, the liquid fuel flows into the cavity of the oil thrower through the oil inlet 2, and enters the interior of the oil thrower through the diverter 3, so that the fuel injection amount reaches each oil hole through the splitter channel 4 to be equal, and then flows through the special-shaped spoiler vanes in turn 5 and bubble-type spoiler 6, due to the high-speed rotation of the disc main body 1, the fuel is thrown at the spoiler blade and the spoiler area, and after being torn, crossed, and changed, the atomization effect of the liquid flow is better, The larger the expansion cone angle, the more fully mixed with the air in the combustion chamber. And the hedge nozzle 7 makes the tissue burn more fully, and the outlet temperature field is more eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com