Hollow prefabricated concrete pile and machining method thereof

A technology of prefabricated concrete and processing method, applied in the direction of manufacturing tools, sheet pile walls, infrastructure engineering, etc., can solve the problem of high construction cost, and achieve the effects of low equipment and electricity cost, weight reduction, and easy transportation and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

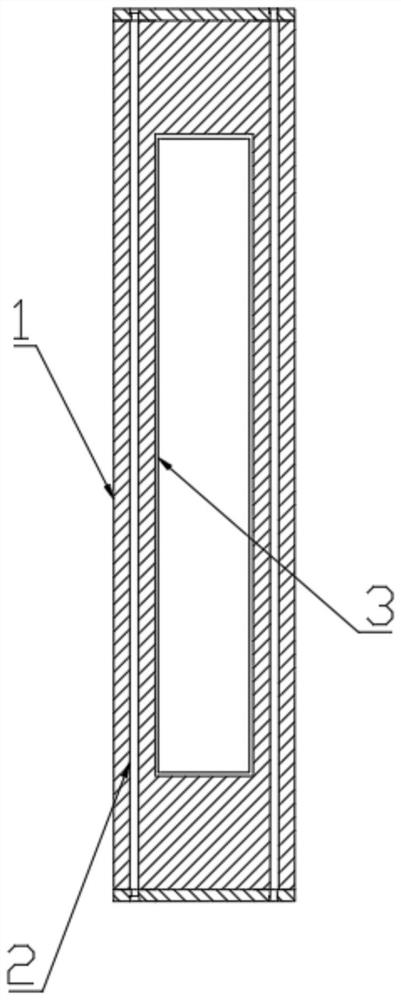

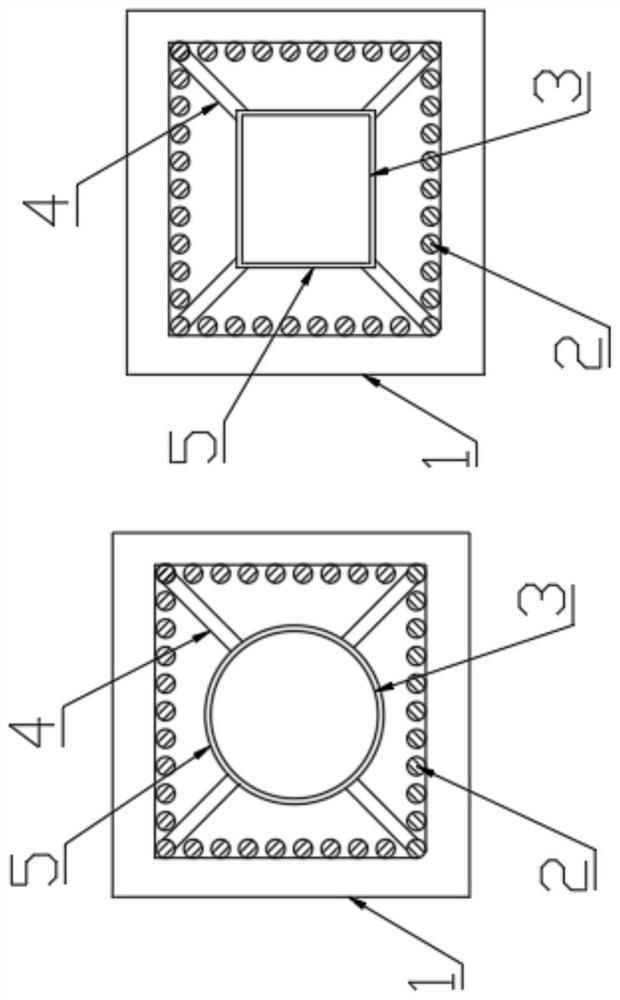

[0038] Such as figure 1 As shown, a hollow prefabricated concrete pile includes: a pile body 1, a main reinforcement 2, a core pipe 3, and a pile body 1. The pile body 1 is square or rectangular and formed by pouring precast concrete. There are multiple main reinforcements 2, which are located inside the pile body 1 and combined with the pile body 1. The main reinforcements 2 are bound into a reinforcement cage through spiral reinforcement. The distance between the main reinforcement 2 and the outer surface of the pile body 1 is 0-10mm farther than the existing standard. The main reinforcement 2 is provided with a pier head and is limited by an end plate. The core tube 3 is fixed to the center of the pile body 1 after being connected with the steel cage. The core tube 3 is a hollow round tube or square tube. The two ends of the core tube 3 are closed. the cavity,

[0039] The number of the core tube 3 is one or more, and when the section of the pile body 1 is square, a core ...

Embodiment 2

[0044] Other parts are identical with embodiment, except the fixing mode of core pipe 3 and reinforcement cage, as image 3 As shown, the core pipe 3 is fixed to the reinforcement cage through multiple sets of well-tac-toe supports 6 .

[0045] Correspondingly, a processing method of a hollow prefabricated concrete pile is disclosed, such as Figure 5 , 6 shown, including the following steps:

[0046] S1. To prepare concrete, mix cement, aggregate, water, admixtures, and admixtures in a certain proportion to form concrete.

[0047] S2. Fabrication of reinforcement cage. After the main reinforcement 2 is cut, pier head operation is performed. Multiple main reinforcement 2 are positioned through the end plate.

[0048] S3. Install the core tube 3. After the two ends of the core tube 3 are closed, insert the steel cage. The distance between the two ends of the core tube 3 and the two ends of the steel cage is the same. The distance between the side of the core tube 3 and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com