Electrolysis equipment and application thereof

A kind of electrolysis equipment and equipment technology, applied in the direction of electrolysis components, electrolysis process, oxidized water/sewage treatment, etc., can solve the problem that the reduction of sulfate radicals into elemental sulfur cannot be realized, and achieve convenient operation, simple equipment structure, and high-efficiency transformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 sodium chloride mass concentration affects available chlorine content

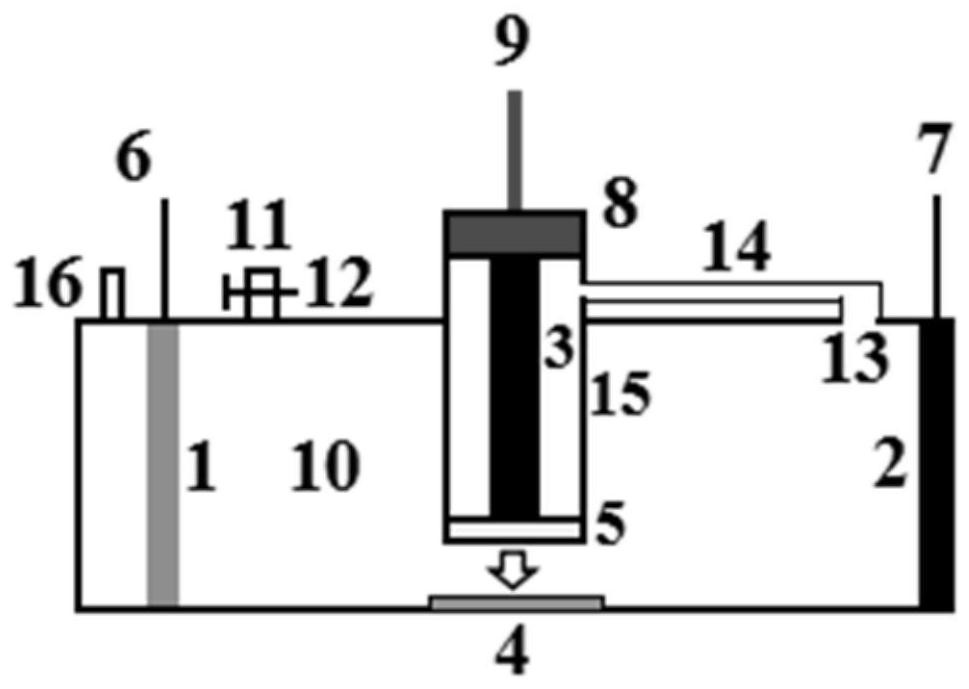

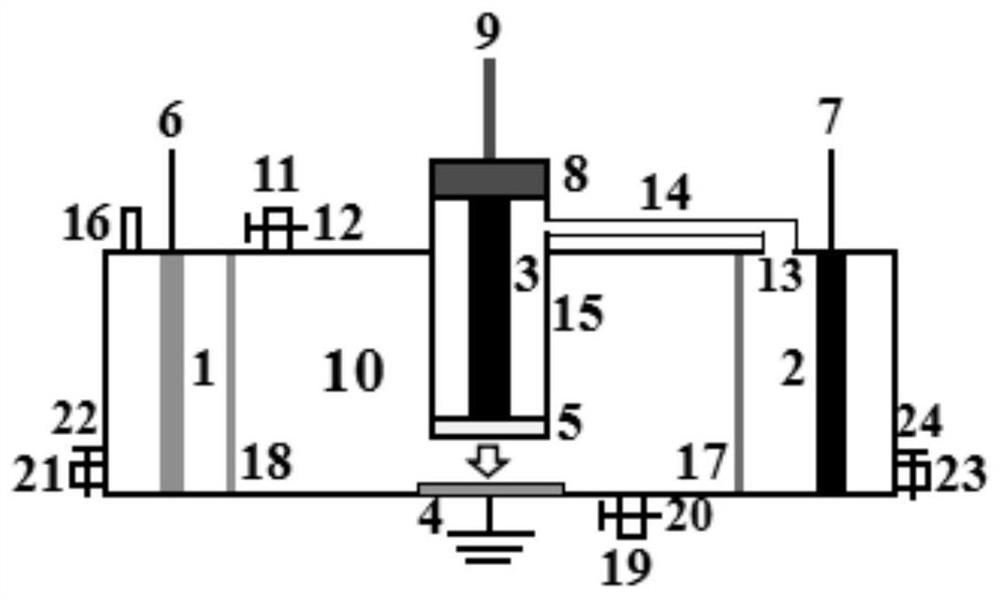

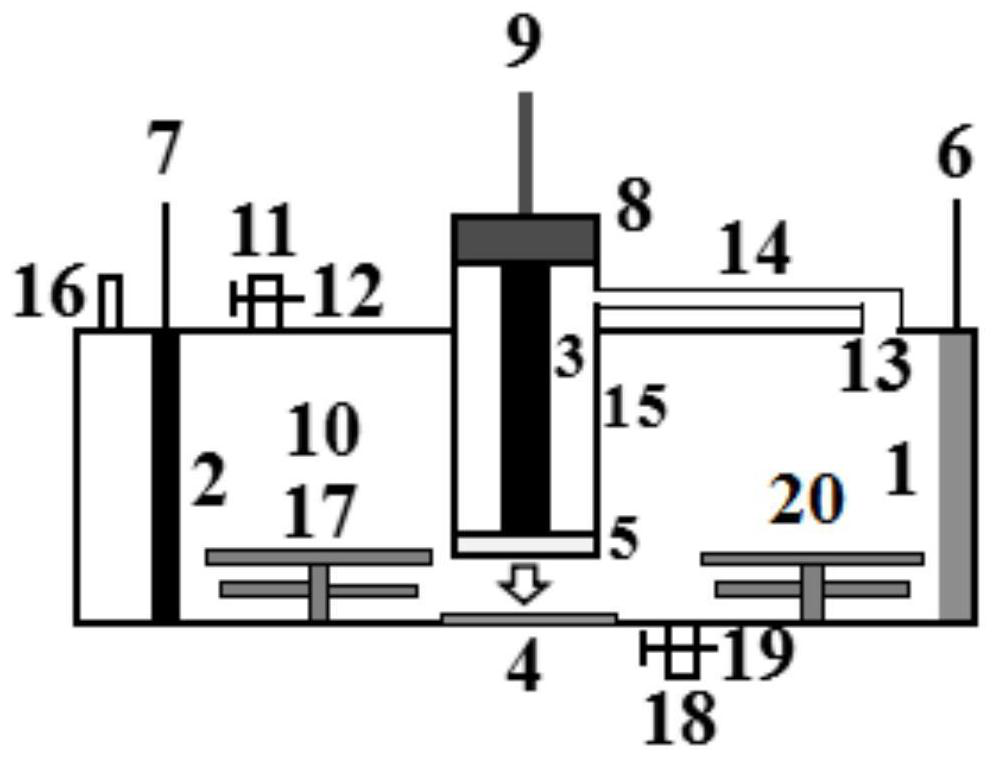

[0047] Such as figure 1 As shown, the device includes an electrolytic cell 10, a DC power supply and a low-temperature plasma discharge power supply; the electrolytic cell 10 includes a first electrode region, a high voltage region and a second electrode region; the first electrode region is a cathode region , the second electrode area is an anode area; the upper end of the cathode area is provided with a hydrogen exhaust port 16 and a solution inlet 11, and the inside of the cathode area is provided with a cathode electrode 1 with a cathode wire 6; A high-voltage line 9, a high-voltage electrode cover 15 and a ground electrode 4 are provided in sequence from top to bottom, and a high-voltage tap 8, a high-voltage electrode 3 and an aeration head 5 are sequentially provided inside the high-voltage electrode cover 15 from top to bottom; the upper end of the anode area is provided with T...

Embodiment 3

[0060] Embodiment 3 Low-temperature plasma discharge power supply influence on available chlorine content

[0061] Experimental equipment and method are the same as embodiment 1, wherein the sodium chloride aqueous solution concentration is 15%, connects the DC power supply and the low-temperature plasma discharge power supply and handles the sodium chloride aqueous solution for 1.5h, the voltage of the DC power supply is 100V, and the current is 550A, The low-temperature plasma discharge power supply voltage is 75kV, and the power is 10kW, 30kW, 50kW, 70kW, 90kW, 100kW, and six groups of sodium hypochlorite solutions are obtained.

[0062] The detection of available chlorine content is the same as in Example 1, and the test results of this example are shown in Table 3.

[0063] Table 3 Effect of low temperature plasma discharge power on available chlorine content

[0064]

[0065] As can be seen from Table 3, when the power of the low-temperature plasma discharge power su...

Embodiment 4

[0068]Adopt technology of the present invention, experimental equipment and method are the same as embodiment 1, wherein the concentration of sodium chloride aqueous solution is 15%, connect DC power supply and low-temperature plasma discharge power supply and dispose of sodium chloride aqueous solution for 1.5h, the voltage of DC power supply is 100V , the current is 550A, the low-temperature plasma discharge power supply voltage is 75kV, and the power is 100kW to obtain a sodium hypochlorite solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com