Shrinkage-warping-resistant ASA 3D printing material and preparation method thereof

A printing material and anti-shrinkage technology, applied in the direction of additive processing, etc., can solve problems such as physical and mental health of operators that affect the forming accuracy of parts, shrinkage and warpage of materials, etc., to reduce molecular chain peristalsis, reduce surface tension, and improve thermal stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

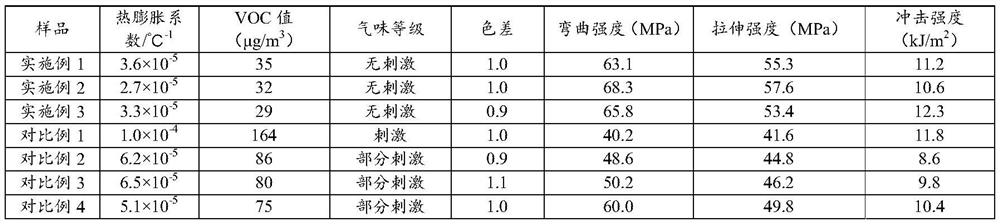

Examples

Embodiment 1

[0025] A kind of anti-shrinkage warping ASA 3D printing material, the components are calculated by weight percentage: ASA resin 70%, HIPS resin 15%, organicized montmorillonite 5% (the layer spacing of organicized montmorillonite in this embodiment Preferred is 2.4 nm), acrylonitrile-butadiene-styrene grafted maleic anhydride 5%, zinc stearate 2%, antioxidant 1010 1% and stearic acid 2%.

[0026] A method for preparing an ASA 3D printing material resistant to shrinkage and warpage, comprising the following steps:

[0027] (1) ASA resin, HIPS resin, organic montmorillonite, acrylonitrile-butadiene-styrene grafted maleic anhydride, zinc stearate and antioxidant 1010 were vacuum-dried respectively, and each group after drying The parts are weighed according to the following weight percentage ratio: a kind of anti-shrinkage and warping ASA3D printing material, the components are calculated by weight percentage: ASA resin 70%, HIPS resin 15%, organic montmorillonite 5%, acrylonitri...

Embodiment 2

[0033] A kind of anti-shrinkage warping ASA 3D printing material, the components are calculated by weight percentage: ASA resin 65%, HIPS resin 20%, organicized montmorillonite 6% (the layer spacing of organicized montmorillonite in this embodiment Preferably 3.5nm), acrylonitrile-butadiene-styrene grafted glycidyl methacrylate 6%, calcium stearate 1%, antioxidant 168 1% and liquid paraffin 1%.

[0034] A method for preparing an ASA 3D printing material resistant to shrinkage and warpage, comprising the following steps:

[0035] (1) ASA resin, HIPS resin, organic montmorillonite, acrylonitrile-butadiene-styrene grafted glycidyl methacrylate, calcium stearate and antioxidant 168 are vacuum-dried respectively, and after drying The components are weighed according to the following weight percentage ratio: an anti-shrinkage and warping ASA 3D printing material, the components are calculated by weight percentage: ASA resin 65%, HIPS resin 20%, organic montmorillonite 6% , acryloni...

Embodiment 3

[0041]A kind of anti-shrinkage warping ASA 3D printing material, the components are calculated by weight percentage: ASA resin 75%, HIPS resin 12%, organicized montmorillonite 7% (the layer spacing of organicized montmorillonite in this embodiment Preferred are 3.8 nm) styrene, grafted glycidyl methacrylate 4%, magnesium stearate 0.5%, antioxidant CA 0.5% and polyethylene wax 1%.

[0042] A method for preparing an ASA 3D printing material resistant to shrinkage and warpage, comprising the following steps:

[0043] (1) ASA resin, HIPS resin, organic montmorillonite, styrene-grafted glycidyl methacrylate and magnesium stearate were vacuum-dried respectively, and each component after drying was weighed according to the following weight percentage ratio : An anti-shrinkage and warping ASA 3D printing material, the components are calculated by weight percentage: ASA resin 75%, HIPS resin 12%, organic montmorillonite 7%, styrene grafted glycidyl methacrylate 4 %, magnesium stearate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com