High-toughness and high-cohesiveness C50-strength fiber concrete and preparation method thereof

A technology of fiber concrete and high cohesion, which is applied in the direction of climate sustainability, sustainable waste treatment, and solid waste management. Adhesive force and strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] 1) Add 6 parts by mass of water reducer to 2 / 3 of the total water volume, which is recorded as mixed solution 1; add 5.6 parts of shrinkage reducer and 1.6 parts of defoamer to the total water volume of 3 One-third of the water is recorded as mixed solution 2, and the total amount of water is 180 parts;

[0081] 2) Mix 4.5 parts of ramie fiber, 1020 parts of gravel, 715 parts of river sand, 340 parts of cement, 125 parts of fly ash, 30 parts of straw ash, 12 parts of silica fume, 1 part of nano silicon, 7.8 parts of basalt fiber, 17 parts CaCO 3 Whiskers were divided into three parts according to the mass fraction, and then a part of ramie fiber, basalt fiber, CaCO 3 Sprinkle the whiskers evenly in the disc mixer, then place a portion of crushed stone, river sand, cement, fly ash, straw ash, silica fume, and nano-silicon in the disc mixer in order, and stir for 1 min;

[0082] 3) In the same way, add the other two ingredients into the pan mixer and stir evenly;

[00...

Embodiment 2

[0089] 1) Add 5.5 parts by mass of water reducer to 2 / 3 of the total water volume, which is recorded as mixed solution 1; add 6 parts of shrinkage reducer and 1.7 parts of defoamer to the total water volume of 3 One-third of the water is recorded as mixed solution 2, and the total water content is 175 parts;

[0090] 2) Mix 4.5 parts of ramie fiber, 1020 parts of gravel, 715 parts of river sand, 340 parts of cement, 110 parts of fly ash, 30 parts of straw ash, 11 parts of silica fume, 2 parts of nano silicon, 7.8 parts of basalt fiber, 17.2 parts CaCO 3 Whiskers were divided into three parts according to the mass fraction, and then a part of ramie fiber, basalt fiber, CaCO 3 Sprinkle the whiskers evenly in the disc mixer, then place a portion of crushed stone, river sand, cement, fly ash, straw ash, silica fume, and nano-silicon in the disc mixer in order, and stir for 1 min;

[0091] 3) In the same way, add the other two ingredients into the pan mixer and stir evenly;

[0...

Embodiment 3

[0098] 1) Add 6 parts by mass of water reducer to 2 / 3 of the total water volume, which is recorded as mixed solution 1; add 6 parts of shrinkage reducer and 1.7 parts of defoamer to the total water volume of 3 One-third of the water is recorded as mixed solution 2, and the total amount of water is 180 parts;

[0099] 2) 4.6 parts of ramie fiber, 1020 parts of gravel, 715 parts of river sand, 340 parts of cement, 115 parts of fly ash, 35 parts of straw ash, 12 parts of silica fume, 2 parts of nano silicon, 7.9 parts of basalt fiber, 17.2 parts CaCO 3 Whiskers were divided into three parts according to the mass fraction, and then a part of ramie fiber, basalt fiber, CaCO 3 Sprinkle the whiskers evenly in the disc mixer, then place a portion of crushed stone, river sand, cement, fly ash, straw ash, silica fume, and nano-silicon in the disc mixer in order, and stir for 1 min;

[0100] 3) In the same way, add the other two ingredients into the pan mixer and stir evenly;

[0101]...

PUM

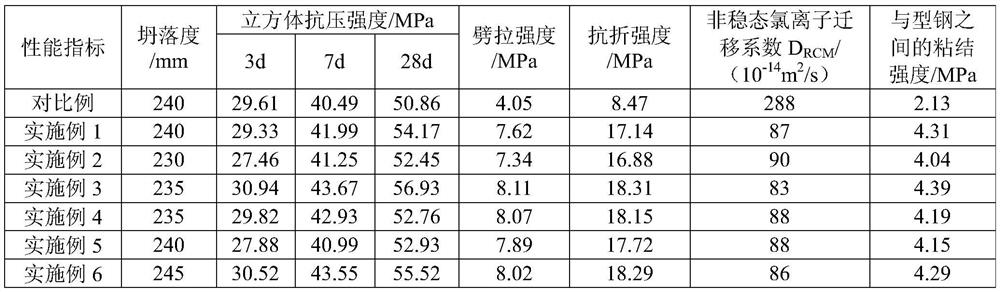

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com