Power bogie based on novel motor suspension structure and upper swing bolster

A power bogie and frame technology, applied in the direction of the bogie, the transmission device driven by the motor, the device for lateral relative movement between the bottom frame and the bogie, etc. system problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

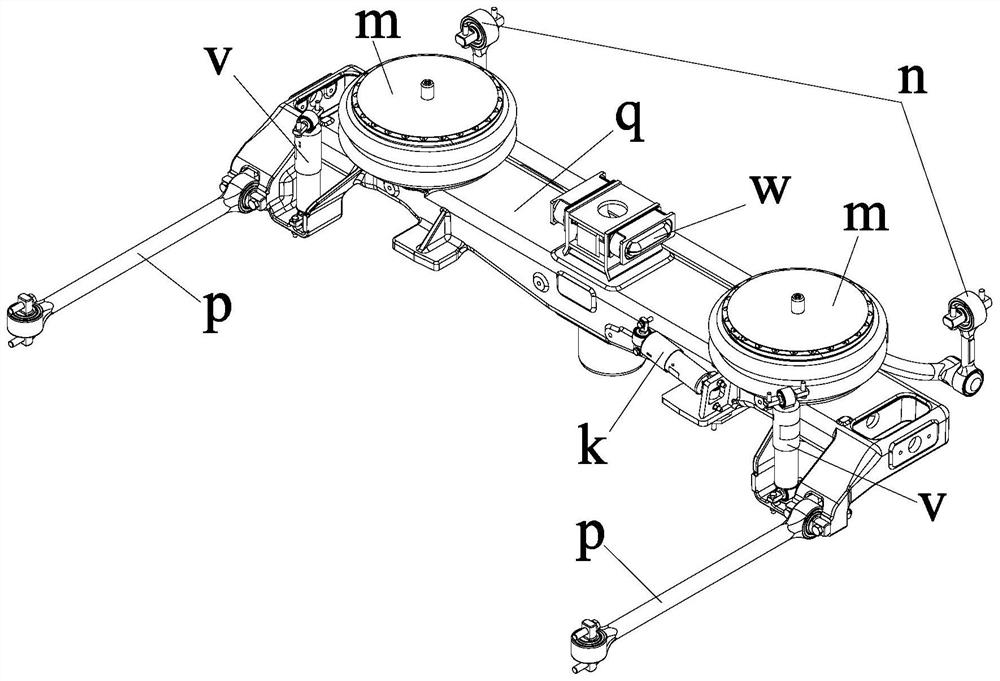

[0056] like Figure 8 to Figure 19 As shown, the present invention is based on a new motor suspension structure and a power bogie with an upper bolster, which includes a frame, a wheel set device composed of wheels and axles, and the frame includes two frame side beams 1-1 and two frame beams 1 -2. The frame side beam 1-1 includes a side beam middle section 1-1-1 at a lower position as the connecting part of two bird wings and two bird wing-shaped wings symmetrically fixed to both ends of the side beam middle section 1-1-1. The cantilever section 1-1-2 of the side beam, the cantilever section 1-1-2 of the bird wing-shaped side beam is formed by connecting an upward tilted section and a horizontal extension section extending horizontally outward;

[0057] It is characterized in that the bogie also includes an easy-to-retract shaft gearbox, a side beam single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com