Metal granulation method and equipment thereof

A kind of granulation equipment and granulation technology, which is applied in the field of ultrasonic application, can solve the problem of unstable material particle shape, achieve high sphericity, good protection, and reduce the effect of metal granulation wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

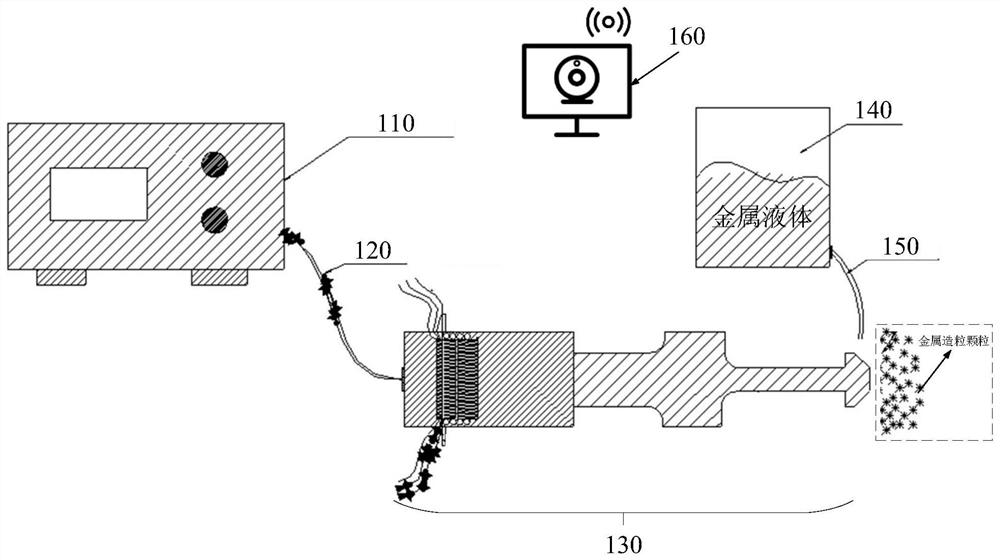

[0048] Please refer to figure 1 , which shows a schematic structural diagram of a metal granulation equipment provided by an exemplary embodiment of the present invention. Among them, the metal granulation equipment includes an ultrasonic power controller 110 , an ultrasonic power cord 120 , an ultrasonic granulation device 130 , a granulation material box 140 , a granulation material delivery pipe 150 and a control assembly 160 .

[0049] The ultrasonic power controller 110 is connected to the ultrasonic granulation device 130 through the ultrasonic power line 120 , wherein the ultrasonic power controller 110 is used for starting and shutting down the metal granulation equipment, and for adjusting the ultrasonic frequency of the ultrasonic granulation device 130 .

[0050] The ultrasonic granulation device 130 is also connected to the granulation material box 140 through the granulation material delivery pipe 150, the granulation material box 140 is used to load the metal liq...

Embodiment 2

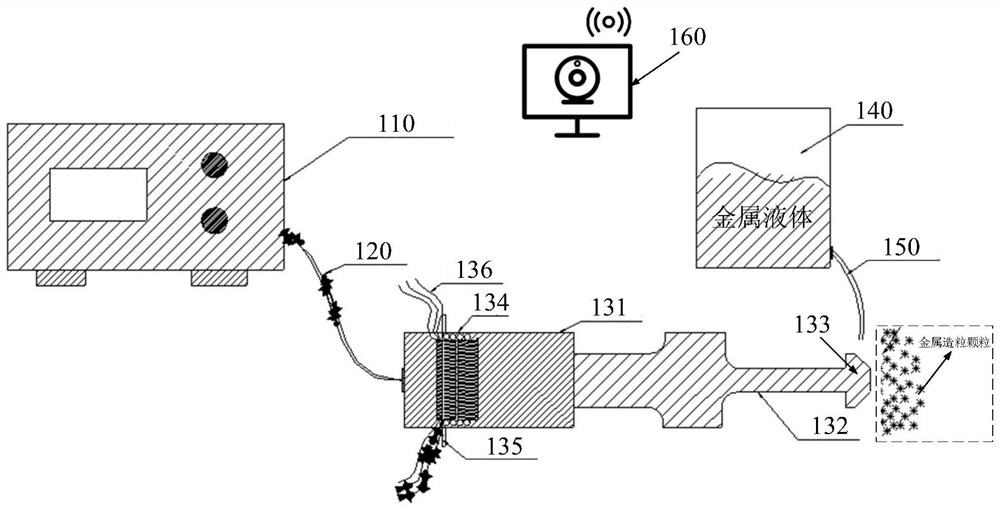

[0054] Please refer to figure 2 , which shows a schematic structural diagram of a metal granulation equipment provided in another exemplary embodiment of the present invention.

[0055] Optionally, the ultrasonic granulation device 130 is composed of an ultrasonic transducer 131 , an ultrasonic horn 132 and an ultrasonic horn probe 133 connected in sequence.

[0056] The ultrasonic transducer 131 is used to convert the electric power set by the control component 160 into a target ultrasonic frequency.

[0057] The ultrasonic horn 132 is used for granulation operation at the target ultrasonic frequency to obtain metal granulated particles, and the ultrasonic horn probe 133 is used for product processing operation using the metal granulated particles.

[0058] Optionally, the ultrasonic horn probe 133 is made of TC4 titanium alloy material. TC4 titanium alloy material has the characteristics of high heat resistance and high strength, and has the characteristics of good corrosi...

Embodiment 3

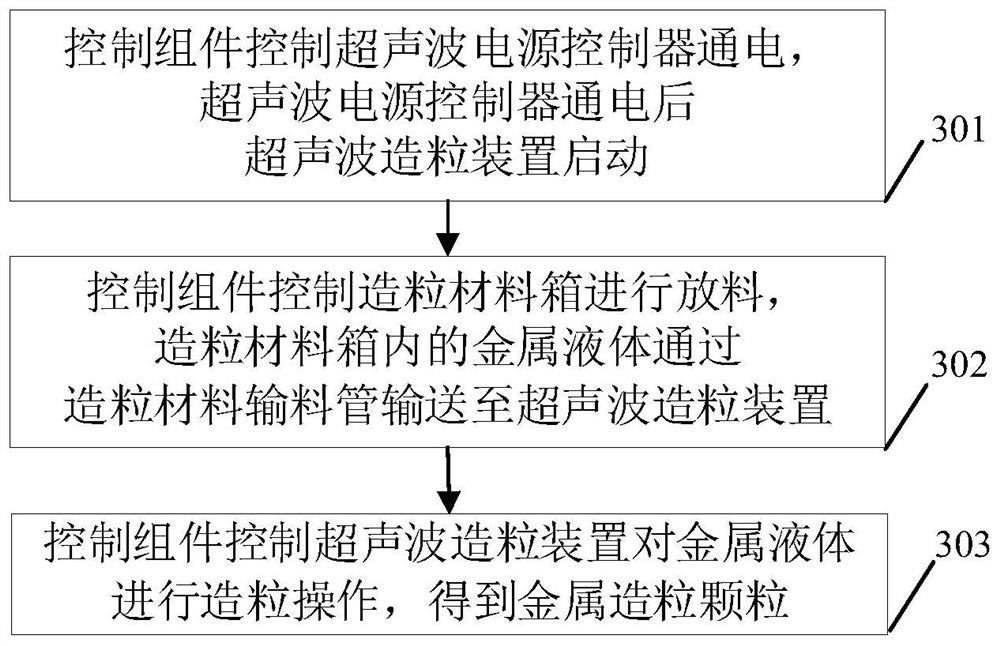

[0070] Please refer to image 3 , which shows a schematic flow chart of a metal granulation method provided by an exemplary embodiment of the present invention, which is applicable to the metal granulation equipment of the above embodiment, and the method is as follows.

[0071] Step 301, the control component controls the ultrasonic power controller to be powered on, and the ultrasonic granulation device is started after the ultrasonic power controller is powered on.

[0072] Step 302, the control component controls the granulation material box to discharge, and the metal liquid in the granulation material box is transported to the ultrasonic granulation device through the granulation material delivery pipe.

[0073] Step 303, the control component controls the ultrasonic granulation device to perform granulation operation on the metal liquid to obtain metal granulation particles.

[0074] To sum up, the embodiment of the present application provides a metal granulation meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com