Die with stretching male die and bottom hole punching stripping block integrally formed

A technology for forming molds and stripping blocks, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the qualified rate of products, deformation of bottom holes, etc., and achieve the effect of smooth feeding and improving the qualified rate of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

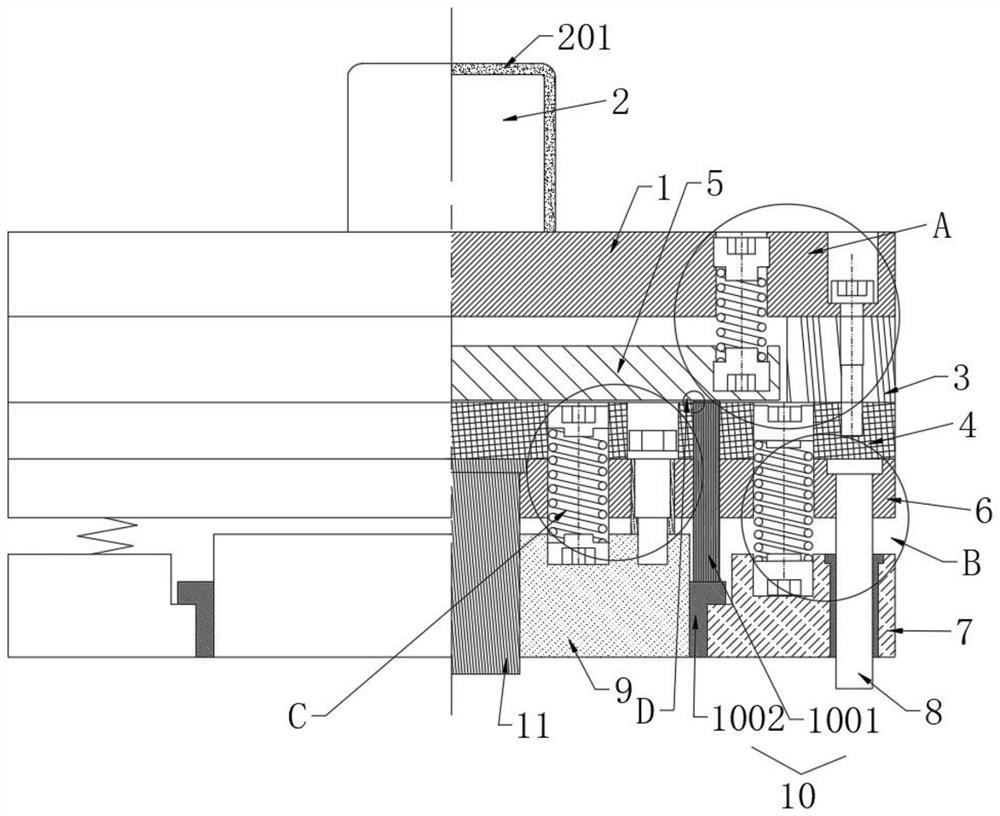

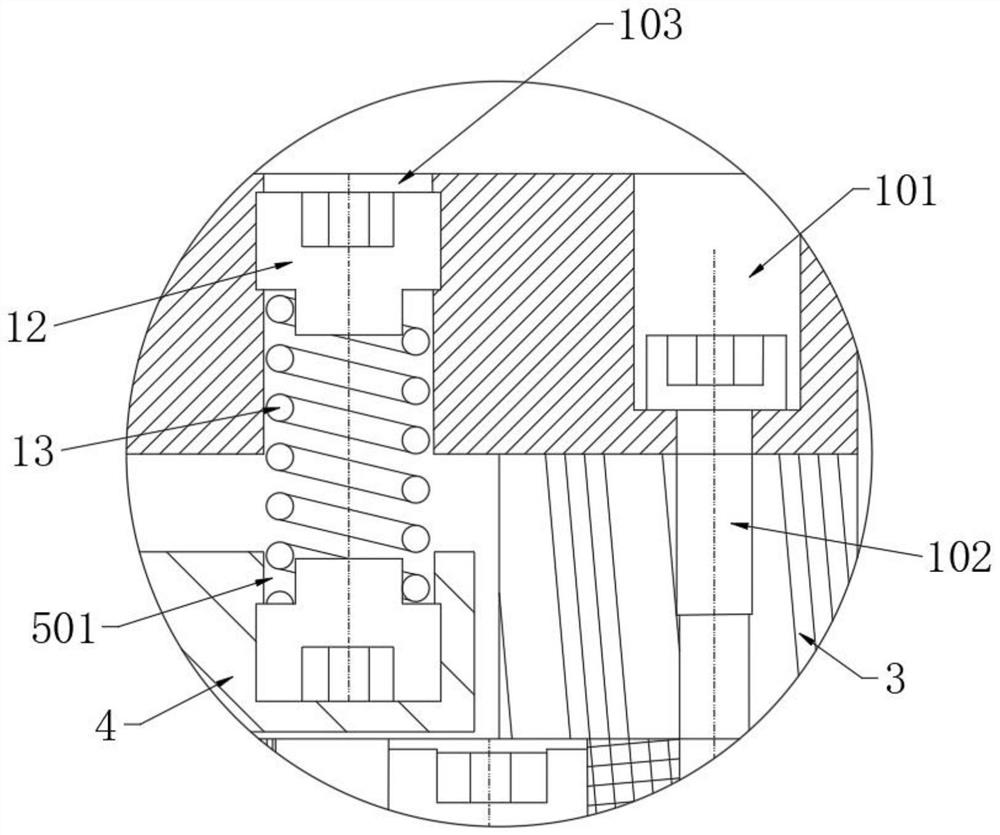

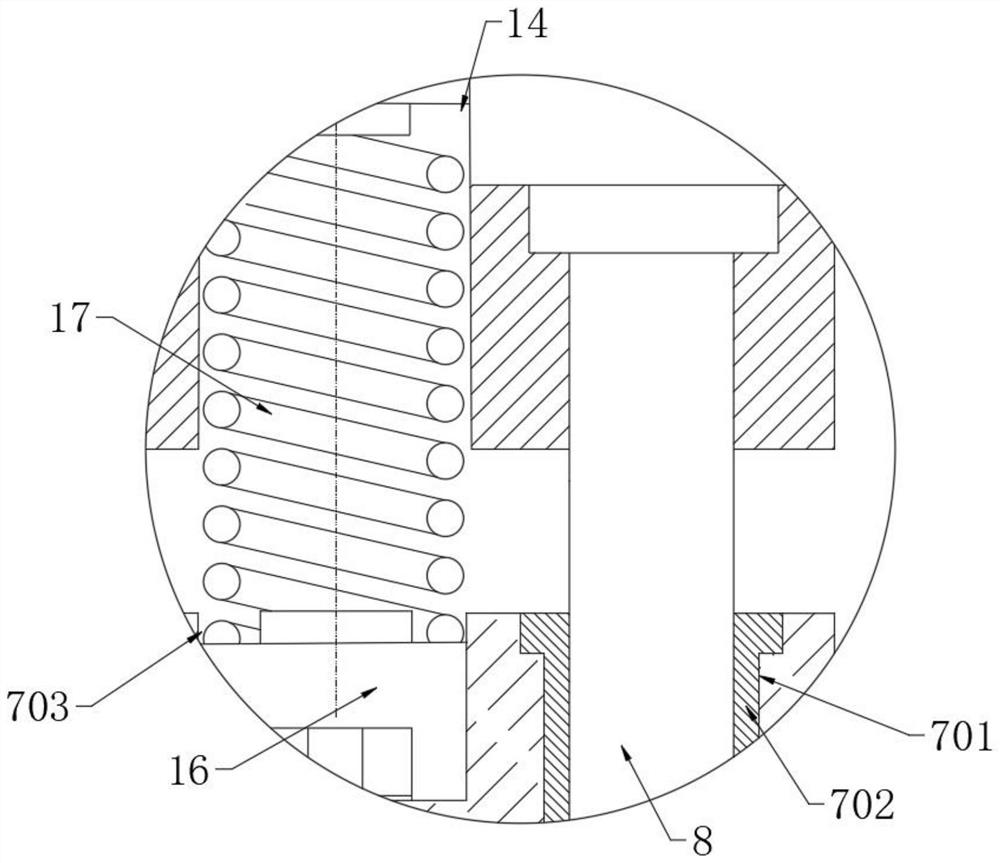

[0038] Please refer to the attached Figure 1-6 , a stretching punch and a punching hole stripping block integrally formed mold, comprising:

[0039] Wherein, a mold handle 2 is welded at the center of the upper surface of the upper template 1 , and a frosted sleeve 201 is set on the mold handle 2 .

[0040] Further, the set mold handle 2 plays the role of driving the upper template 1 to press down under the force.

[0041] Wherein, the first fixing plate 3 is formed on the lower surface of the upper template 1 .

[0042] Further, the provided first fixing plate 3 plays a role of fixing and linking the upper mold 1 and the upper mold backing plate 4 together.

[0043] Wherein, the upper mold backing plate 4 is fixedly installed under the first fixing plate 3 .

[0044] Wherein, the pushing washer 5 is formed in the first fixing plate 3 and is located between the upper mold 1 and the upper mold backing plate 4 .

[0045] Wherein, the second fixing plate 6 is welded and fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com