A kind of magnetic adsorption material and preparation method thereof

A magnetic adsorption material and magnetic technology, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of large number of large pores, poor magnetic persistence, and reduced adsorption capacity of activated carbon, and achieve fluidity Good, high proportion of mesopores, good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

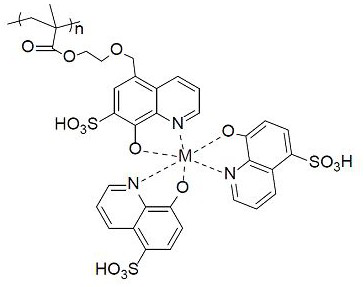

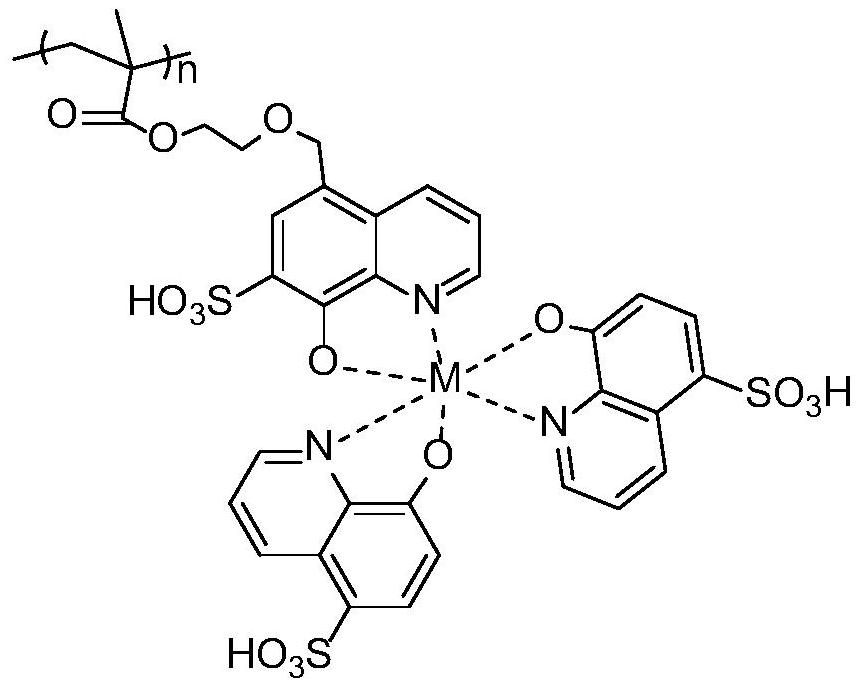

[0032] A method for preparing a magnetic adsorption material, comprising the following steps:

[0033] 1. Preparation of polymer precursors

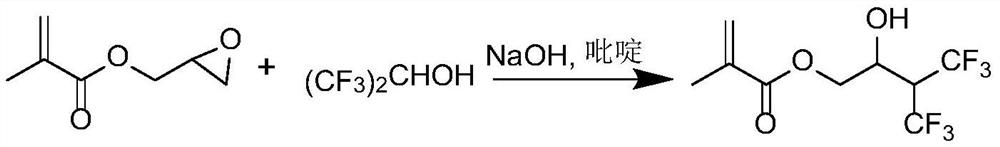

[0034] 1) using glycidyl methacrylate and hexafluoroisopropanol as raw materials to prepare fluorine-containing methacrylate monomers;

[0035]

[0036] 2) Using 6-aminoquinoline as a raw material to undergo a substitution reaction with 6-chloro-1-hexanol, followed by an esterification reaction with methacryloyl chloride to obtain a quinoline derivative with a double bond at the end;

[0037]

[0038] 3) Put 5 mmol of fluorine-containing methacrylate monomer and 10 mmol of quinoline derivatives into a reaction flask, add 0.1 mmol of initiator AIBN and solvent DMF, and circulate nitrogen / vacuum three times, and place at 60-70 The polymerization reaction was carried out at ℃ for 2-3 hours. After the reaction, the polymer was precipitated in methanol, and the polymer precursor was obtained by suction filtration and drying.

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com