Negative plate and lithium ion battery

A lithium-ion battery and negative electrode technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of poor cycle performance, safety problems, distortion and deformation of lithium-ion batteries, and achieve improved cycle stability and safety performance , good cycle performance and safety performance, and the effect of reducing the possibility of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the silicon-based material of the present invention comprises the following steps:

[0056] 1) Carbon-coated Li-SiO x Materials and organic solvents containing oxygen-containing salts are mixed and dispersed to form a suspension solution;

[0057] 2) Drying the mixed solution in step 1) to obtain a silicon-based material.

[0058] Specifically, the carbon-coated Li-SiO in step 1) x The material may be purchased commercially, as long as the carbon material in the carbon coating satisfies the definition of the above-mentioned carbon material.

[0059] The organic solvent in step 1) can be N-methylpyrrolidone (NMP), ethanol, acetone, toluene.

[0060] Based on the total mass of the silicon-based material, the mass percentage of the oxygen-containing salt in step 1) is 0.05-5%.

[0061] The drying method in step 2) is not particularly limited, and any method that can make the mixed solution in step 1) dry falls within the protection scope of th...

Embodiment 1

[0091] The preparation method of the negative plate of the present embodiment comprises the following steps:

[0092] 1) The purchased carbon-coated Li-SiO 1.07 The material is placed in Al(PO 3 ) 3 After stirring in the nano-suspension for 60 minutes, the mixed system was dried, and then filtered to obtain a silicon-based material;

[0093] Among them, 2.6wt%Al(PO 3 ) 3 Nanosuspensions were obtained commercially.

[0094] Carbon-coated Li-SiO 1.07 The material and the silicon-based material are weighed, and the difference is calculated to obtain that the mass of the above-mentioned oxygen-containing salt coating layer accounts for 0.5% of the total mass of the silicon-based material. The particle size D of the above silicon-based material v10Si 5.8 μm, D v50Si 9 μm, D v90Si is 15 μm.

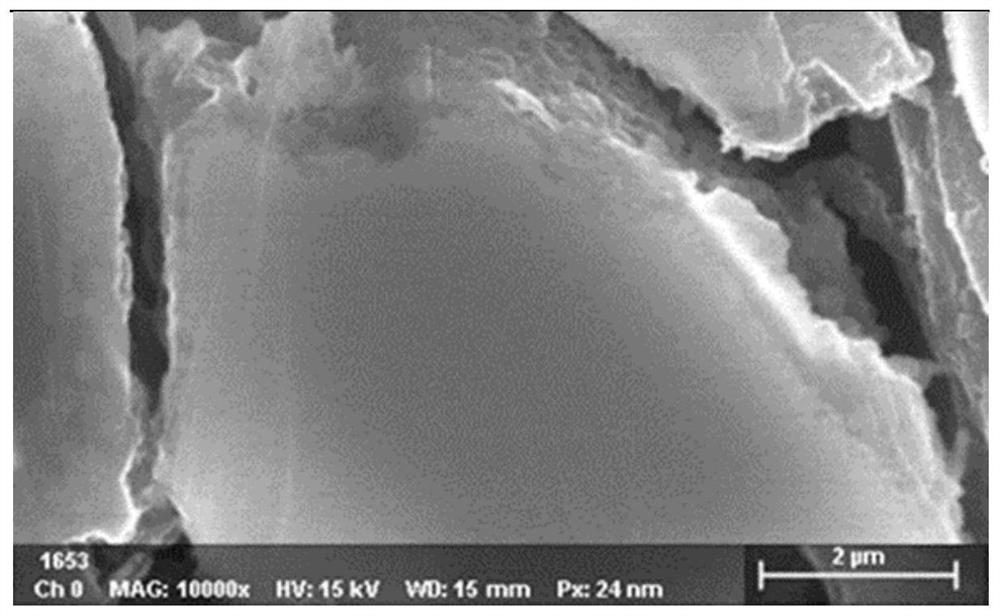

[0095] SEM was used to observe the surface morphology of silicon-based materials, figure 1 It is the surface SEM image of the silicon-based material in Example 1 of the present inven...

Embodiment 2

[0101] The preparation method of the negative plate of the present embodiment comprises the following steps:

[0102] 1) The purchased carbon-coated Li-SiO 1.04 The material is put into La(PO 3 ) 3 After stirring in the nano-suspension for 60 minutes, the mixed system was dried, and then filtered to obtain a silicon-based material;

[0103] Among them, 3.1wt%La(PO 3 ) 3 Nanosuspensions are commercially available.

[0104] Carbon-coated Li-SiO 1.04 The material and the silicon-based material are weighed, and the difference is calculated to obtain that the mass of the above-mentioned oxygen-containing salt coating layer accounts for 0.5% of the total mass of the silicon-based material. The particle size D of the above silicon-based material v10Si 4.2 μm, D v50Si 5.9 μm, D v90Si is 10.4 μm.

[0105] 2) The silicon-based material in step 1) is mixed with graphite particles at a mass ratio of 15:85, and the silicon-based material and graphite particles, styrene-butadiene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com