Method for integrally improving corrosion resistance of 7-series aluminum alloy battery pack shell

An overall lifting, aluminum alloy technology, applied to the surface coating device, furnace type, coating and other directions, can solve the problems of unclean electrophoresis drainage, many processes, easy corrosion resistance, etc., to solve the problem of poor drainage. net effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

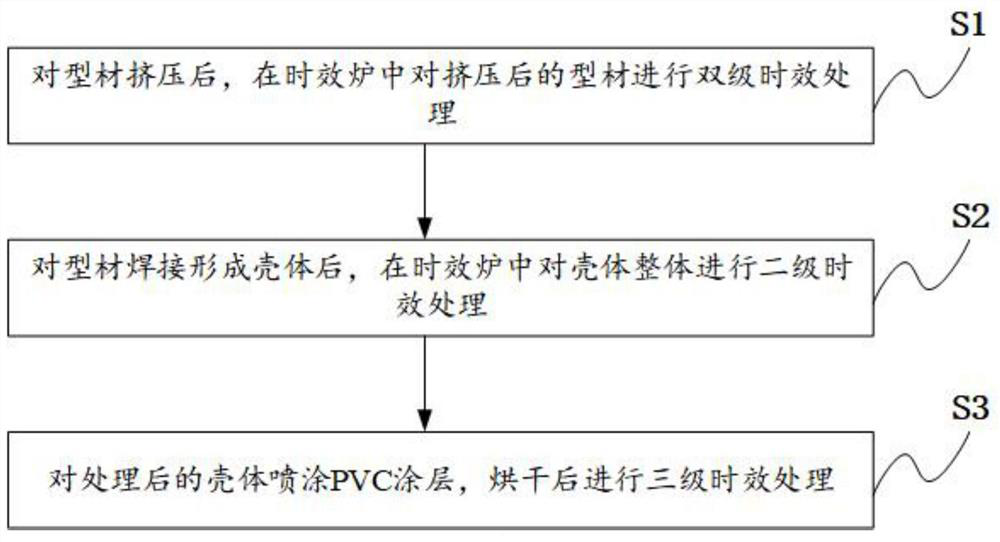

[0021] Such as figure 1 Shown is a schematic diagram of the main flow of an embodiment of a method provided by the present invention. In this embodiment, the method includes the steps of:

[0022] Step S1, after extruding the profile, performing a double-stage aging treatment on the extruded profile in an aging furnace;

[0023] In a specific embodiment, the two-stage aging treatment includes the first-stage aging treatment: setting the temperature range of the aging furnace within 80 to 150 degrees, and performing heat treatment on the extruded profile in the aging furnace for a predetermined time, The predetermined time range is 4 to 8 hours; the two-stage aging treatment includes a second-stage aging treatment: after the extruded profile has undergone the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com