Formaldehyde oxidation reactor

A technology of oxidation reactor and oxidizer, which is applied in chemistry/physics/physicochemistry fixed reactor, oxidation preparation of carbonyl compounds, organic chemistry, etc. It can solve the problem of unused process waste heat, inconvenient replacement of catalyst, and reduced heat exchange efficiency and other problems to achieve the effect of overcoming stress cracking, solving stress corrosion problems, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

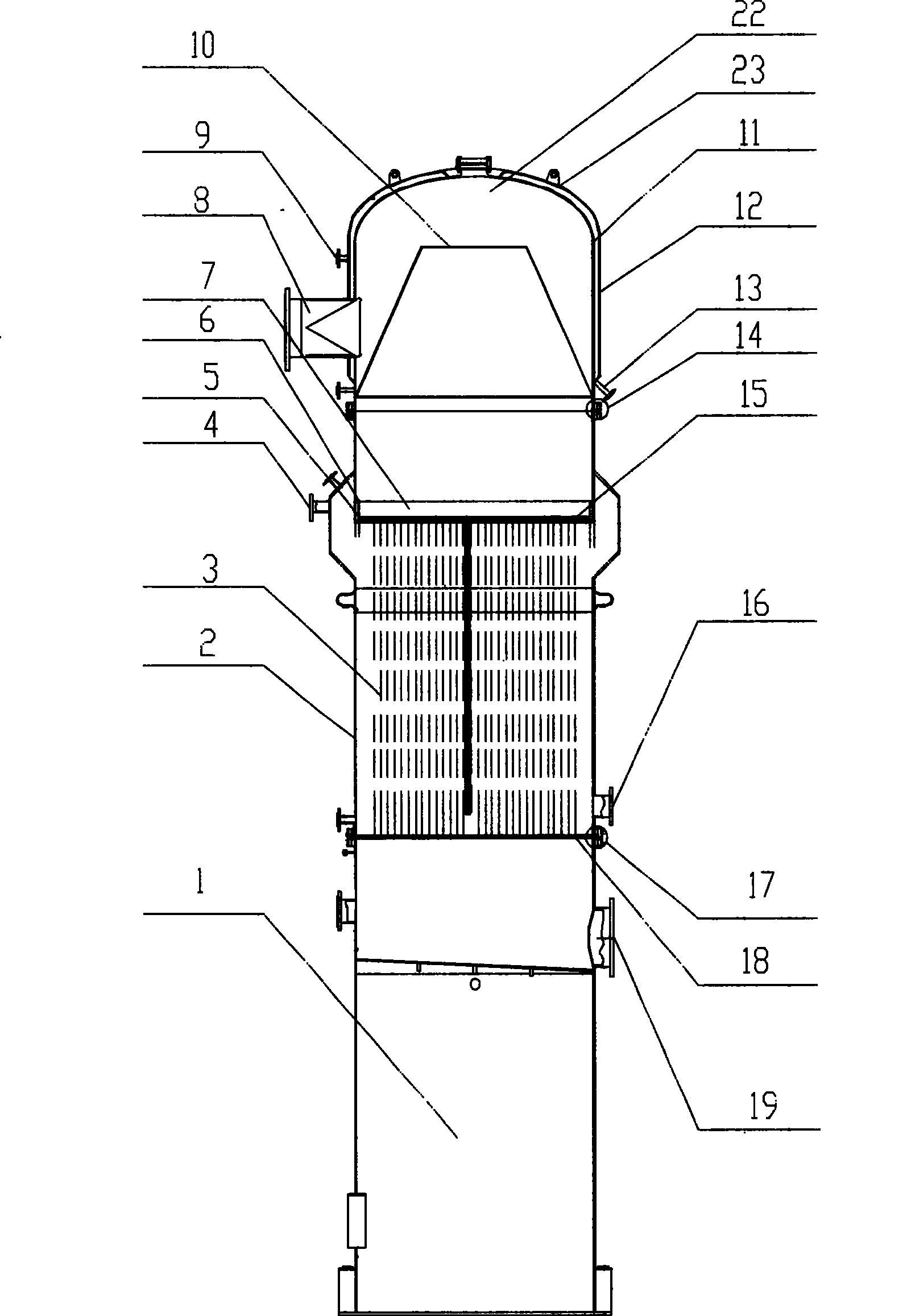

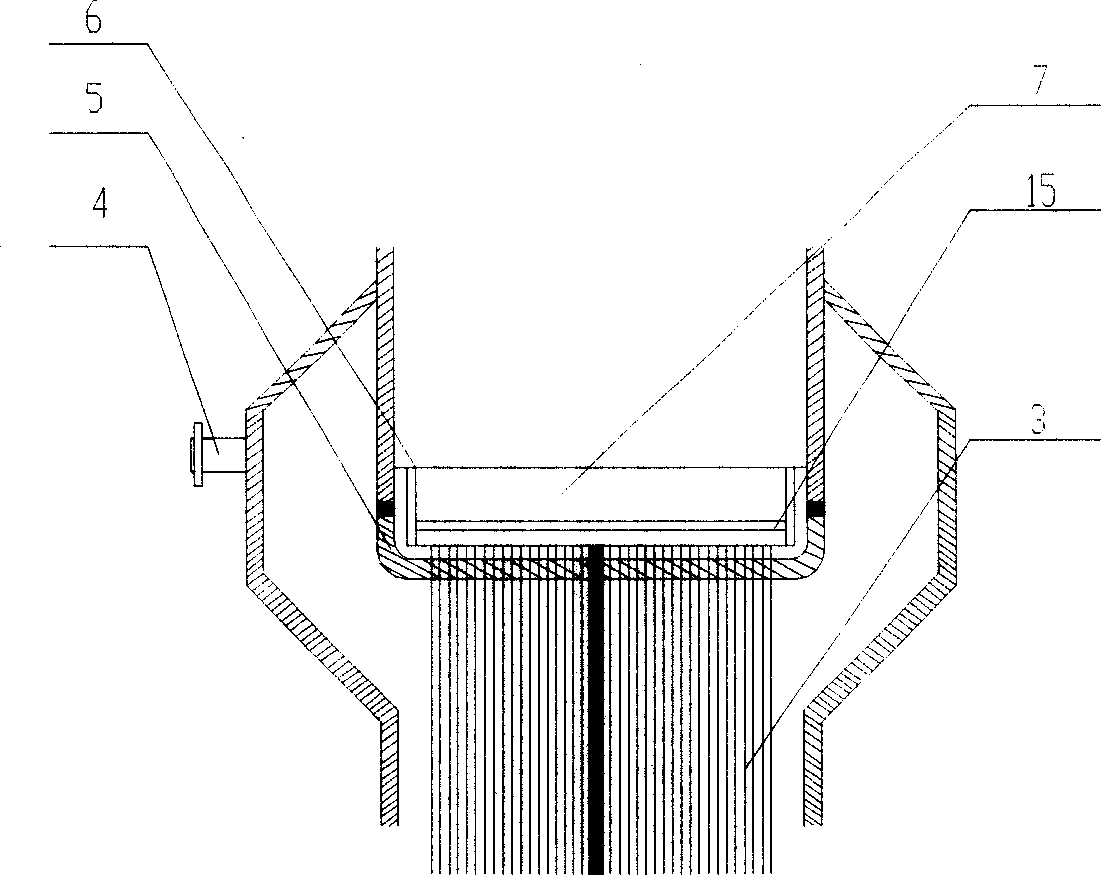

[0062] see first figure 1 The schematic diagram of the shown formaldehyde oxidation reactor of the present invention, the formaldehyde oxidation reactor of the present invention comprises:

[0063] top cover 22;

[0064] The oxidizer main cylinder 2 connected to the top cover 22 is provided with a catalyst layer 7 for oxidative dehydrogenation reaction to generate formaldehyde gas;

[0065] A device connected to the main cylinder body 2 of the oxidizer to output the generated formaldehyde gas, in this case, the device is a skirt 1 provided with a formaldehyde gas outlet 19;

[0066] It is characterized in that the top cover 22 includes:

[0067] The heat preservation jacket 12 is composed of an inner cylinder 11 and an outer cylinder 23 that are sealed and connected, and a heating interlayer is formed between the outer cylinder 23 and the inner cylinder 23;

[0068] Enter the quaternary mixed gas inlet 8 inside the top cover 22 from the outer cylinder 23 and the inner cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com