Condenser pipe for refrigeration device in vending machine

A technology for automatic vending machines and refrigeration devices, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc. It can solve the problems of reducing the condensation effect, increasing the wall thickness of copper tubes, and increasing production costs, so as to achieve less chance of medium precipitation, Effect of reducing working stress and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below through specific examples.

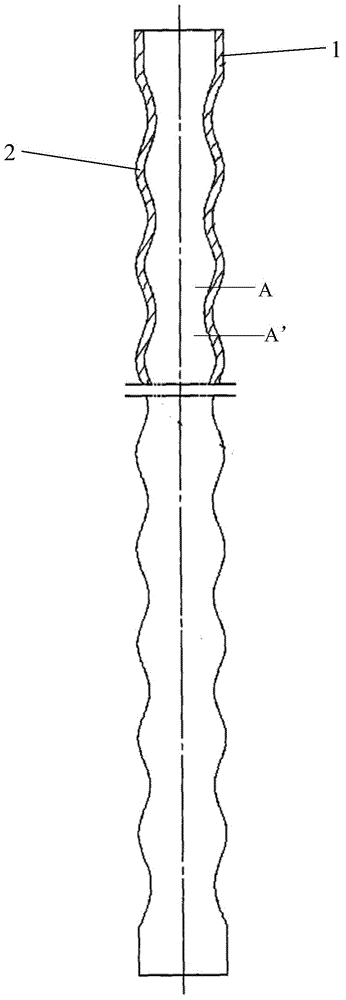

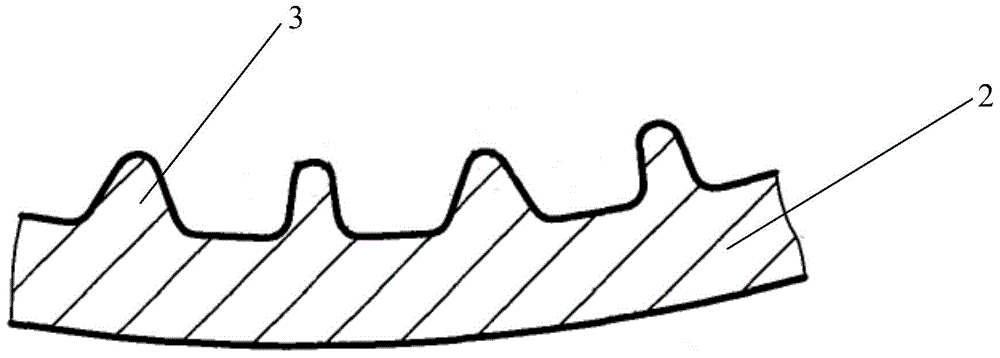

[0023] Condenser tubes used for refrigeration devices in vending machines are made of thin-walled stainless steel, with equal-diameter straight tubes 1 at both ends and corrugated tubes 2 in the middle. Diameter; due to the long condenser tube, a baffle support is installed in the condenser. The corrugated pipe 2 has a full arc structure, and the corrugation is formed by arc-shaped crests and troughs tangentially and uniformly transitioned without any processing stress and avoiding stress corrosion. External threads 3 are evenly distributed on the outer surface of the condenser tube. During heat exchange, the refrigerant changes from a vapor state to a liquid state, and condenses on the outer surface of the metal tube to form a layer of liquid film. The external thread 3 pierces the liquid film, making it quickly form small droplets, along the sinusoidal The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com