Method for simultaneously preparing cellulose nanocrystals and cellulose nanofibers from oil-tea camellia husk

A nanocrystal and nanofiber technology is applied in the field of preparation of nanocellulose, which can solve the problems of high energy consumption, high energy consumption and high production cost by mechanical methods, reduce energy consumption, overcome low product yield, and facilitate the technological process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

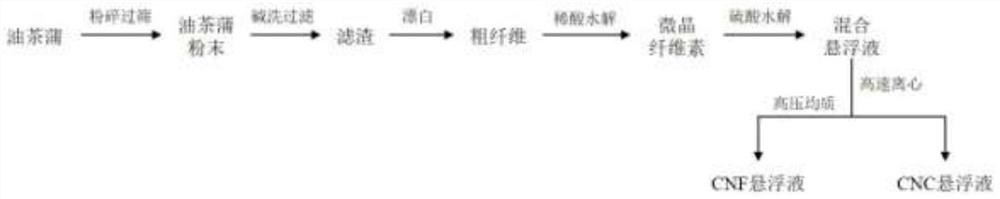

[0033] refer to figure 1 , a method for simultaneously preparing cellulose nanocrystals and cellulose nanofibers from Camellia oleifera, the specific steps are:

[0034] S1. Mechanical treatment: take 100g of Camellia oleifera, dry and pulverize, and pass through a 40-mesh sieve;

[0035] S2. Alkali washing: take 50 g of Camellia oleifera powder obtained in step S1, add 750 mL of 2% NaOH solution, heat in a water bath to 80 ° C, and stir for 2 hours at the same time, filter after the reaction is completed, rinse the filter residue with deionized water, and repeat the alkali washing 4 times , wash the filter residue with water until neutral, and dry at 50°C;

[0036] S3. Bleaching: take 20g of the filter residue obtained in step S2, add 300mL of 1.7%NaClO 2 solution, adjust the pH to 3.5, heat in a water bath to 80°C, and stir for 6 hours at the same time, filter after the reaction, wash the filter residue with water until neutral, and dry at 50°C to obtain the crude fiber of...

Embodiment 2

[0045] A method for simultaneously preparing cellulose nanocrystals and cellulose nanofibers from Camellia oleifera, the specific steps are:

[0046] S1. Mechanical treatment: take 100g of Camellia oleifera, dry and pulverize, and pass through a 60-mesh sieve;

[0047] S2. Alkali washing: take 50 g of Camellia oleifera powder obtained in step S1, add 1000 mL of 4% NaOH solution, heat it in a water bath to 90 ° C, and stir for 2 hours at the same time, filter after the reaction, rinse the filter residue with deionized water, and repeat the alkali washing 3 times , wash the filter residue with water until neutral, and dry at 50°C;

[0048] S3. Bleaching: take 20g of the filter residue obtained in step S2, add 600mL of 1.5%NaClO 2 solution, adjust the pH to 3.0, heat in a water bath to 90°C, and stir for 4 hours at the same time, filter after the reaction, wash the filter residue with water until neutral, and dry at 50°C to obtain the crude fiber of Camellia oleifera;

[0049] ...

Embodiment 3

[0056] A method for simultaneously preparing cellulose nanocrystals and cellulose nanofibers from Camellia oleifera, the specific steps are:

[0057] S1. Mechanical treatment: take 100g of Camellia oleifera, dry and pulverize, and pass through a 40-mesh sieve;

[0058] S2. Alkali washing: take 50 g of Camellia oleifera powder obtained in step S1, add 750 mL of 5% NaOH solution, heat in a water bath to 70 ° C, and stir for 3 hours at the same time, filter after the reaction is completed, rinse the filter residue with deionized water, and repeat the alkali washing 3 times , wash the filter residue with water until neutral, and dry at 50°C;

[0059] S3. Bleaching: take 20g of the filter residue obtained in step S2, add 300mL of 1.5%NaClO 2 solution, adjust the pH to 3.0, heat in a water bath to 70°C, and stir for 6 hours at the same time, filter after the reaction, wash the filter residue with water until neutral, and dry at 50°C to obtain the crude fiber of Camellia oleifera; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com