MXene doping-based composite material and preparation method thereof

A technology of composite materials and raw materials, applied in the field of composite photocatalysts, can solve problems such as underutilization, achieve uniform distribution, low requirements for equipment and equipment, and improve photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

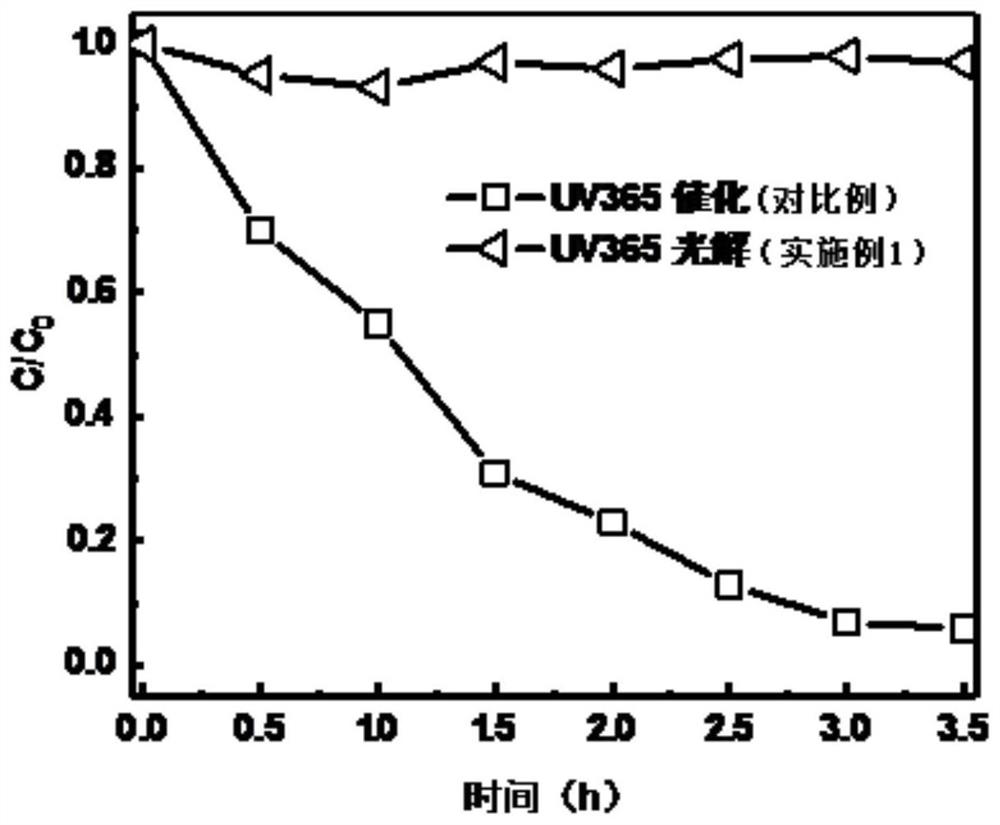

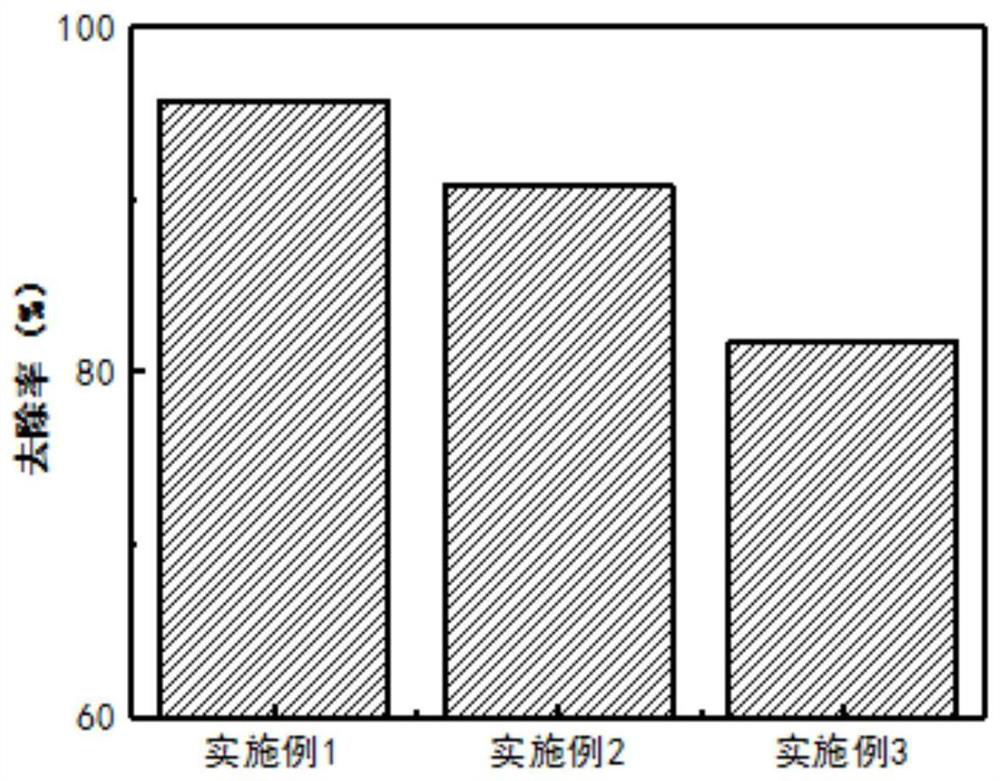

Embodiment 1

[0036] (1) At room temperature, add 2gLiF into a polytetrafluorobeaker filled with 40mL, 9mol / L hydrochloric acid, stir for 3min, then add 2g Mo 2 Ga 2 C. Stir evenly; put the obtained mixed solution into a 37°C constant temperature magnetic stirring water bath, put a polytetrafluoroethylene rotor, stir and react for 100 hours, and obtain the MXene colloidal solution;

[0037] (2) Centrifuge the MXene colloid solution at 4000rmp for 10min, add deionized water and wash it repeatedly 5 times until the pH of the solution is ≥ 6, pour off the supernatant, and at 4°C, separate the precipitates from absolute ethanol and Ultrasonic dispersion with 600W power in deionized water for 2 hours to obtain a suspension solution, centrifuge the suspension solution at 8000rmp for 60min to obtain a blue-black MXene sheet colloid solution;

[0038](3) The blue-black MXene sheet colloidal solution was self-assembled by vacuum filtration using a cellulose carbonate filter membrane with a pore siz...

Embodiment 2

[0044] (1) At room temperature, add 2gLiF into a polytetrafluorobeaker filled with 40mL, 9mol / L hydrochloric acid, stir for 3min, then add 2g Mo 2 Ga 2 C. Stir evenly; put the obtained mixed solution into a 37°C constant temperature magnetic stirring water bath, put a polytetrafluoroethylene rotor, stir and react for 100 hours, and obtain the MXene colloidal solution;

[0045] (2) Centrifuge the MXene colloid solution at 4500rmp for 12min, add deionized water and wash it repeatedly 7 times until the pH of the solution is ≥ 6, pour off the supernatant, and at 4°C, separate the precipitates from absolute ethanol and then Ultrasonic dispersion in deionized water with 700W power for 1.5h to obtain a suspension solution, centrifuge the suspension solution at 8500rmp for 45min to obtain a blue-black MXene lamellar colloid solution;

[0046] (3) The blue-black MXene sheet colloid solution was self-assembled by vacuum filtration using a cellulose carbonate filter membrane with a pore...

Embodiment 3

[0052] (1) At room temperature, add 2gLiF into a polytetrafluorobeaker filled with 40mL, 9mol / L hydrochloric acid, stir for 3min, then add 2g Mo 2 Ga 2 C. Stir evenly; put the obtained mixed solution into a 37°C constant temperature magnetic stirring water bath, put a polytetrafluoroethylene rotor, stir and react for 100 hours, and obtain the MXene colloidal solution;

[0053] (2) Centrifuge the MXene colloid solution at 5000rmp for 15min, add deionized water and wash it repeatedly 10 times until the pH of the solution is ≥ 6, pour off the supernatant, and at 4°C, separate the precipitate from absolute ethanol and then Ultrasonic dispersion with 800W power in deionized water for 1h to obtain a suspension solution, centrifuge the suspension solution at 9000rmp for 30min to obtain a blue-black MXene lamellar colloidal solution;

[0054] (3) The blue-black MXene sheet colloidal solution was self-assembled by vacuum filtration with a cellulose carbonate filter membrane with a por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com