Pixelated thermochromic liquid crystal array system for light stealth

A liquid crystal array and pixelation technology, which is applied to instruments, static indicators, etc., can solve the problems of static color camouflage, etc., and achieve the effects of low cost, guaranteed stealth performance, and low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

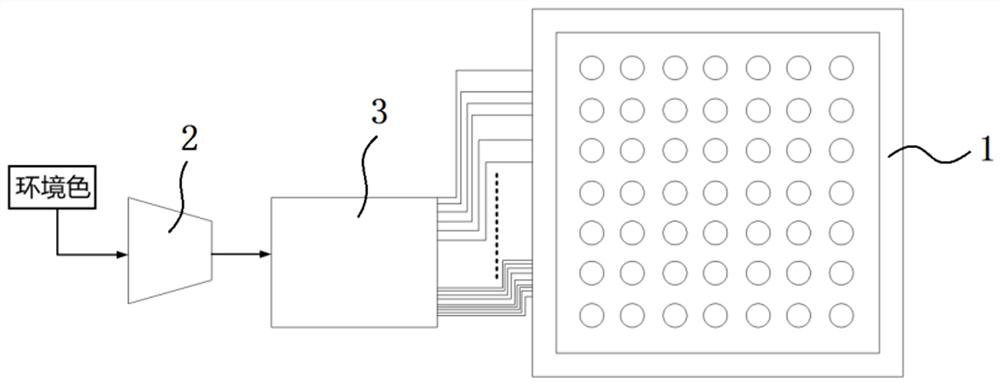

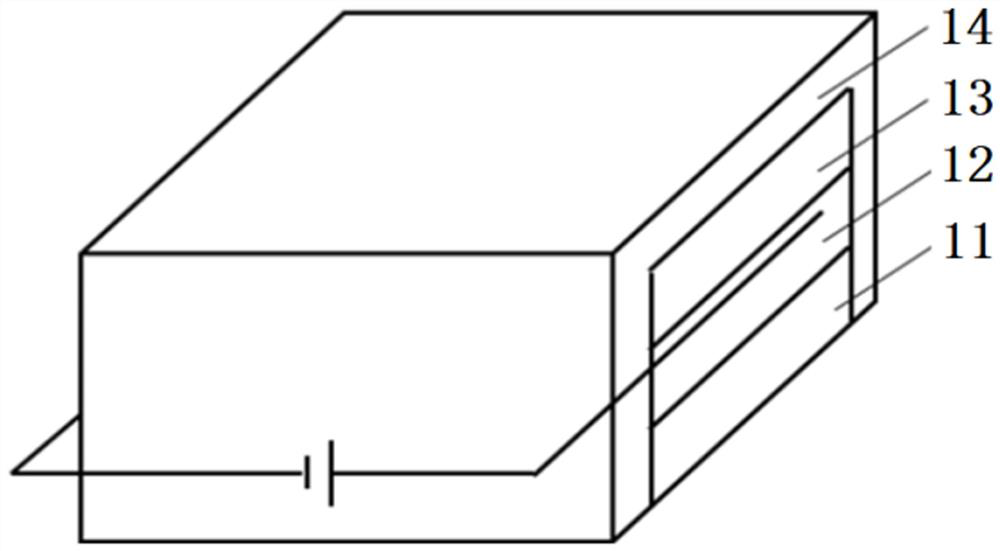

[0022] The temperature of the preparation environment of the pixelated liquid crystal array of the present invention must be strictly controlled below 20°C to ensure the activity of different types of liquid crystals after compounding. figure 1 The substrate shown in is ITO conductive glass, which is cut into small pieces of 1cm×1cm. The size of the selected silicone rubber heating plate is 1cm×1cm. The surface is brushed with hydrogen peroxide solution with a mass concentration of 10%. After drying at room temperature, brush again, and repeat 6 times. The surface is fully hydroxylated, dried at room temperature and coated with a black heat-resistant primer for later use. Configure compound liquid crystal ink, the mass ratio of A-type liquid crystal to B-type liquid crystal is 3:2, apply it on the surface of the pretreated silicone rubber heating plate, and apply a sealing agent on the surface after drying. Epoxy resin is used to seal the substrate and the heating plate coated...

Embodiment 2

[0024] The temperature of the preparation environment of the pixelated liquid crystal array of the present invention must be strictly controlled below 20°C to ensure the activity of different types of liquid crystals after compounding. figure 1 The substrate shown in is FTO conductive glass, cut into small pieces of 1cm×1cm, the size of the selected silicone rubber heating plate is 1cm×1cm, and the surface is brushed with hydrogen peroxide solution with a mass concentration of 10%, and then brushed again after drying at room temperature, repeated 6 times, The surface is fully hydroxylated, dried at room temperature and coated with a black heat-resistant primer for later use. Configure compound liquid crystal ink, the mass ratio of A-type liquid crystal and C-type liquid crystal is 1:2, apply it on the surface of the pretreated silicone rubber heating plate, and apply a sealing agent on the surface after drying. Epoxy resin is used to seal the substrate and the heating plate co...

Embodiment 3

[0026] The temperature of the preparation environment of the pixelated liquid crystal array of the present invention must be strictly controlled below 20°C to ensure the activity of different types of liquid crystals after compounding. figure 1 The substrate shown in is FTO conductive glass, cut into small pieces of 1cm×1cm, the size of the selected silicone rubber heating plate is 1cm×1cm, and the surface is brushed with hydrogen peroxide solution with a mass concentration of 10%, and then brushed again after drying at room temperature, repeated 6 times, The surface is fully hydroxylated, dried at room temperature and coated with a black heat-resistant primer for later use. Configure compound liquid crystal ink, the mass ratio of B-type liquid crystal and C-type liquid crystal is 1:1, apply it on the surface of the pretreated silicone rubber heating plate, and apply a sealing agent on the surface after drying. Epoxy resin is used to seal the substrate and the heating plate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com