Automatic scheduling method based on dynamic collaborative position complementing strategy

A scheduling method and strategy technology, which is applied in the field of electrical measurement, can solve problems such as wear and tear, inaccurate test data of the test bench, and affect the normal test of the test product, so as to ensure accuracy, improve test efficiency and accuracy, and improve test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

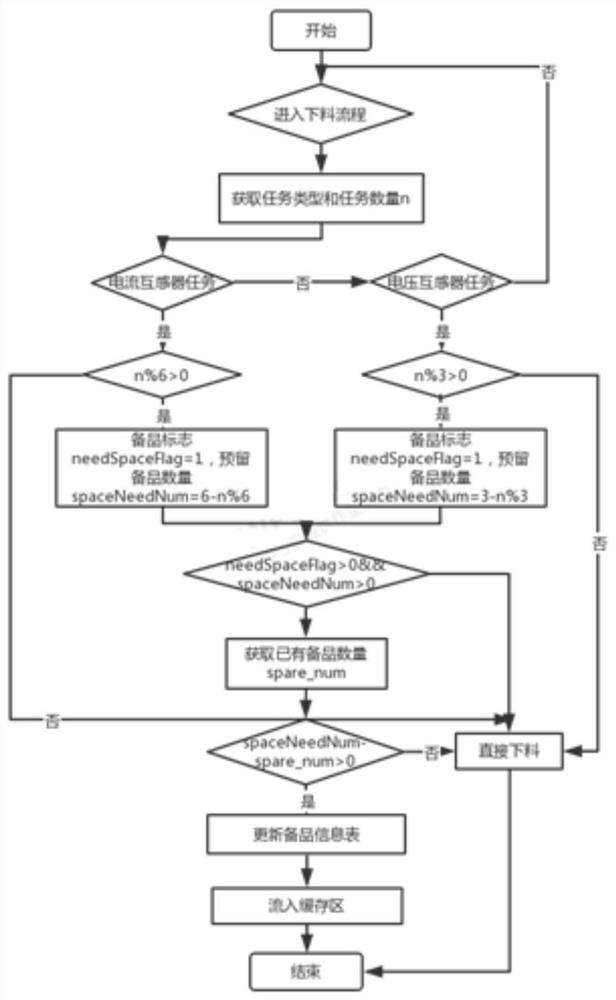

[0028] The present invention provides a technical solution: an automatic scheduling method based on a dynamic collaborative filling strategy, comprising the following steps:

[0029] S11: Obtain the verification type and verification quantity of the transformer in the current transformer verification task;

[0030] S12: Determine the single verification quantity of the current transformer verification task according to the verification type and the preset single verification quantity of the transformer verification line;

[0031] S13: Calculate the number of transformers that need to be completed for the current transformer verification task according to the verification quantity of the current transformer verification task and the determined single verification quantity;

[0032] S2: Control the transformer verification line to start the verification of the transformer;

[0033] S3: Reserve a test sample equal to the number of transformers that need to be completed from the ...

Embodiment 2

[0042] The present invention provides a technical solution: an automatic scheduling method based on a dynamic collaborative filling strategy, comprising the following steps:

[0043] S01: Issue a verification task on the production scheduling platform;

[0044] S02: The control program of the 10kv transformer calibration line receives the task, conducts out-of-warehouse verification, loading, appearance identification, and enters the current station for testing. After the test is completed, it goes to the unloading place after labeling;

[0045] S03: The i-th (i=1, 2, 3..., the initial value of i is 1) transformer enters the blanking process, and obtains task information, including task quantity n and task type;

[0046] S04: According to the task information, judge whether the current transformer is used as a spare part to flow to the spare part buffer area or is normally unloaded; judge whether the task type is CT (current transformer) or PT (voltage transformer), if it is C...

Embodiment 3

[0050] The present invention provides a technical solution: an automatic scheduling method based on a dynamic collaborative filling strategy, comprising the following steps:

[0051] S01: Send a verification task on the production scheduling platform, the number of tasks is 8, the task type is CT (current transformer), and the transformation ratio is 200 / 5;

[0052]S02: The control program of the 10kv transformer calibration line receives the task, conducts out-of-warehouse verification, loading, appearance identification, and enters the current station for testing. After the test is completed, it goes to the unloading place after labeling;

[0053] S03: The i-th (i=1, 2, 3..., the initial value of i is 1) transformer enters the blanking process to obtain task information, including task quantity and task type;

[0054] S04: The current task type is CT (current transformer), the number of tasks is 8, which cannot be divisible by 6, then set the spare parts flag needSpaceFlag=1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com