Tower type photo-thermal power station heliostat scheduling method based on heat absorber temperature control

A technology for temperature control and photothermal power plants, applied in solar collector controllers, solar thermal power generation, solar collectors, etc., can solve problems that cannot directly and reliably reflect the safe operation of heat absorbers, and cannot directly judge heat absorption In order to avoid problems such as the safe operation state of the receiver and the large demand for heat flux density, it can avoid the disturbance of the parameters of the receiver, reduce the mobilization frequency and moving range, and reduce the tracking energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

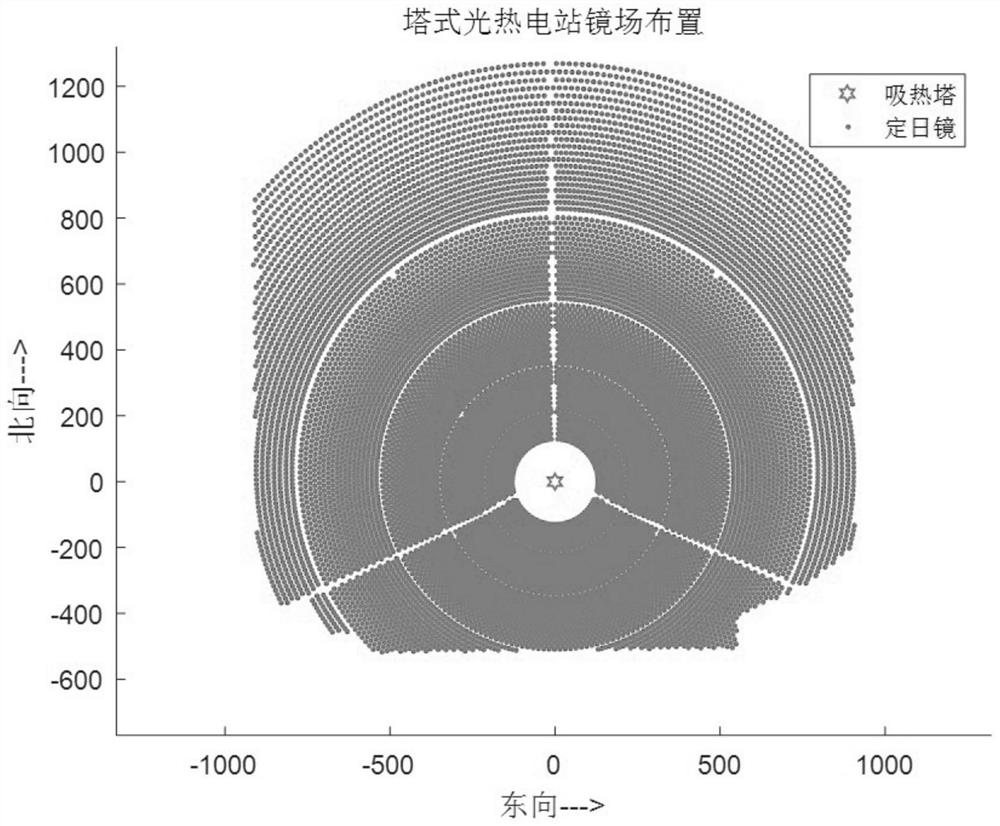

[0051] Take a tower type CSP station as an example: the longitude of the power station is 94.95° east, and the latitude is 43.63° north; the coordinates of the center of the absorber tower are (0,0,0); the center elevation of the absorber 1 is 200m, and the diameter of the heating surface of the absorber 1 is D R , the height of the heating surface of the heat sink 1 is H R . The entire mirror field is equipped with a total of 14,000 heliostats 2, which are distributed in a ring around the heat absorption tower, such as image 3 shown.

[0052] According to step S1 of the method, when 14,000 heliostats 2 are aimed at the 200.0m elevation of the heat absorber 1, the absolute value of the surface temperature, temperature gradient and temperature change rate of the heat absorber 1 corresponding to each time series within a certain period of time are calculated.

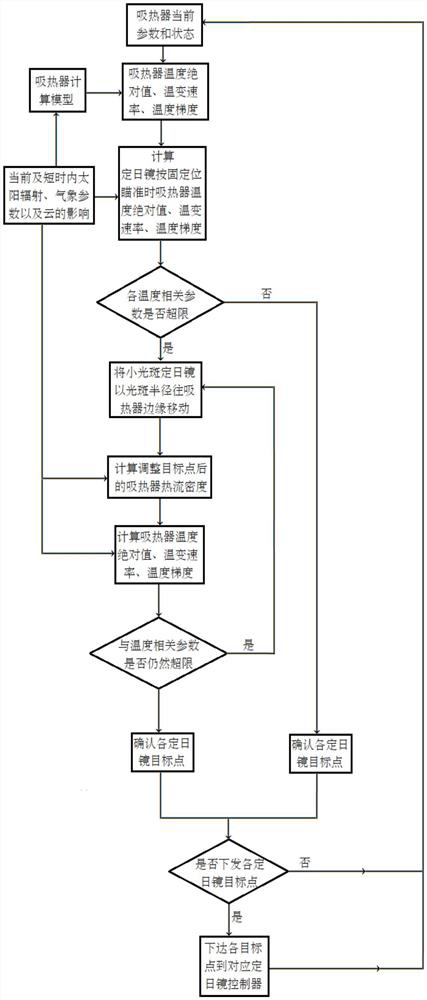

[0053] After calculation, there is the above-mentioned over-temperature problem, and heliostat 2 needs to be dispatc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com