Concrete floor slab reinforcing structure and construction method thereof

A technology for strengthening structures and concrete, applied in building construction, building maintenance, construction, etc., can solve problems such as the limitation of movable range, achieve the effect of convenient construction, prevent deformation and fracture, and improve load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

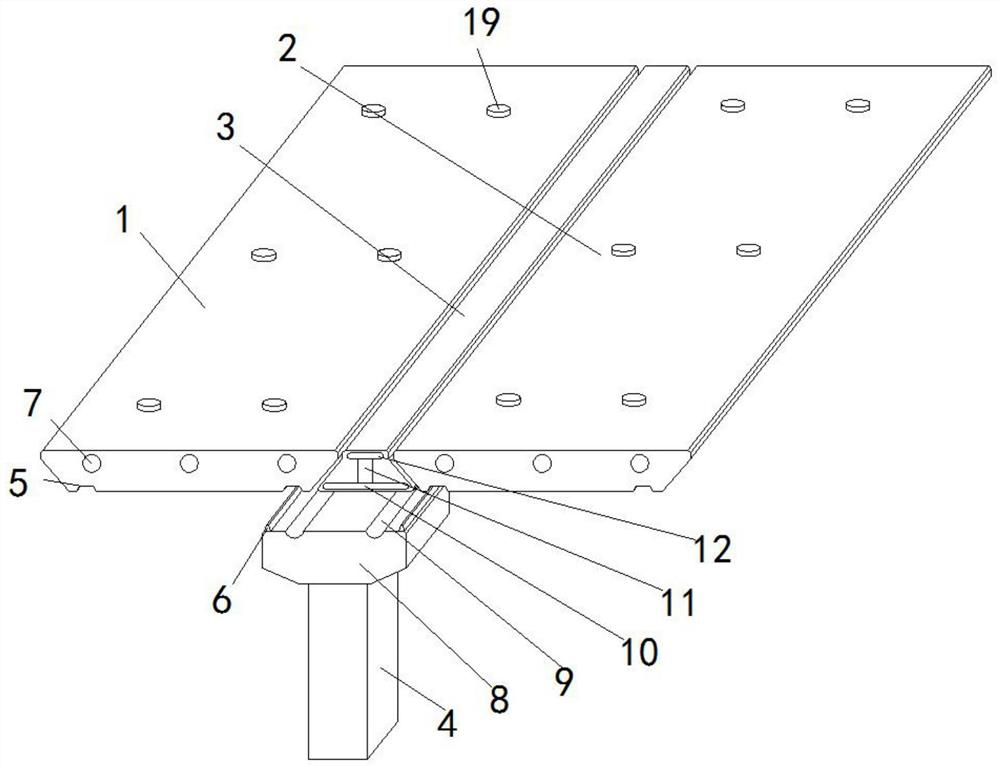

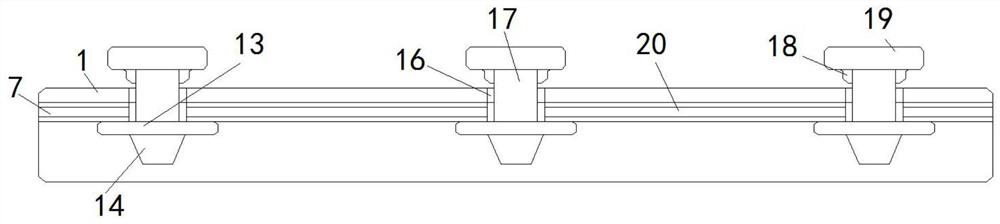

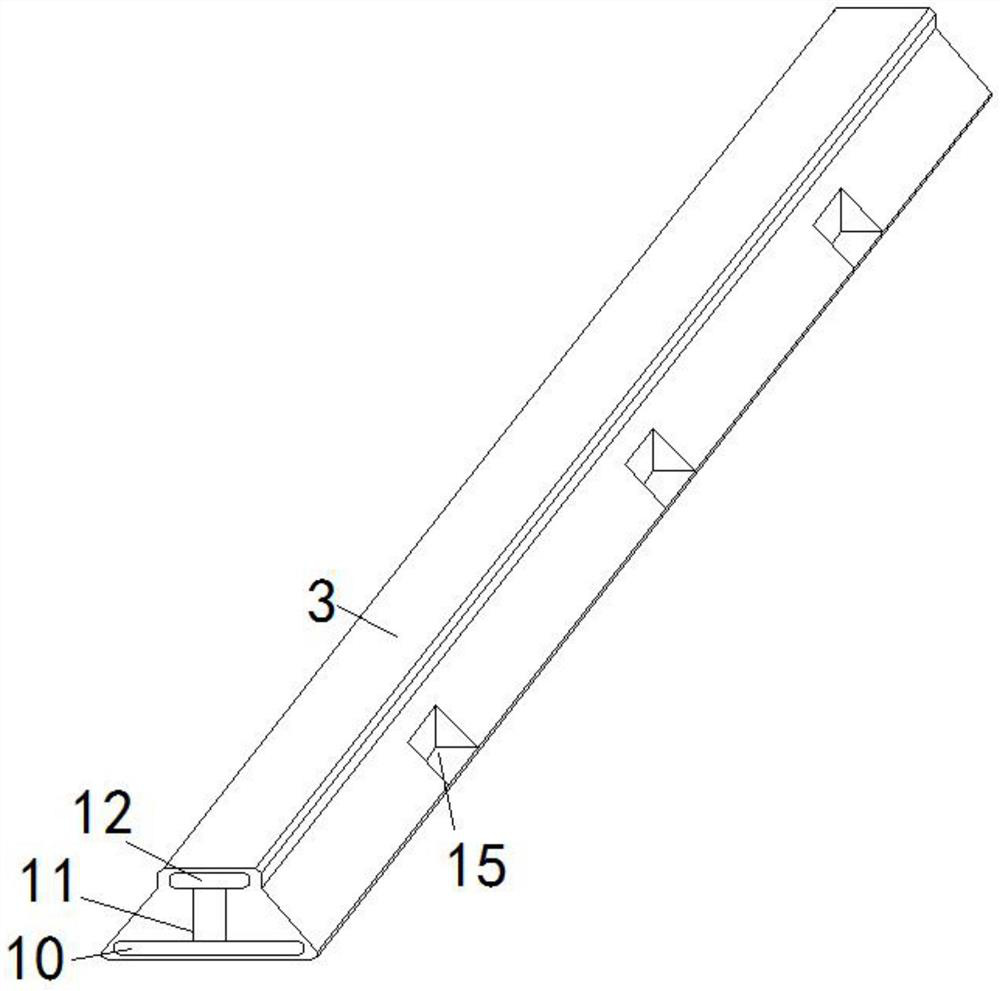

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] see Figure 1 to Figure 3 The concrete floor reinforcement structure includes a first floor 1, a second floor 2, a beam 3 and a pillar 4, the inside of the first floor 1 is fixedly equipped with a reinforcement column 7, and the bottom of the reinforcement column 7 is fixedly installed with a transverse steel plate 13. The bottom of the horizontal steel plate 13 is fixed with a cross column 14, and the inside of the first floor 1 is provided with a perforation 16. The cross beam 3 is located on the opposite side of the first floor 1 and the second floor 2, and the cross beam 3 and the first floor 1 Both are movable connections with the second floor 2, and the top of the transverse steel plate 13 is fixedly installed with a top column 17 that penetrates and extends to the top of the perforation 16, and the outer side of the top column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com