Macro-scale biological nylon fiber containing active ingredients of coffee and preparation method thereof

A technology of active ingredients and biological fibers, which is applied in the field of nylon large biological fibers and their preparation, can solve the problems of poor light resistance and heat resistance of nylon fibers, the active ingredients of coffee are easily destroyed by high temperature, and the nylon fibers do not have antiviral functions. Achieve good compatibility, good virus inhibition, good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

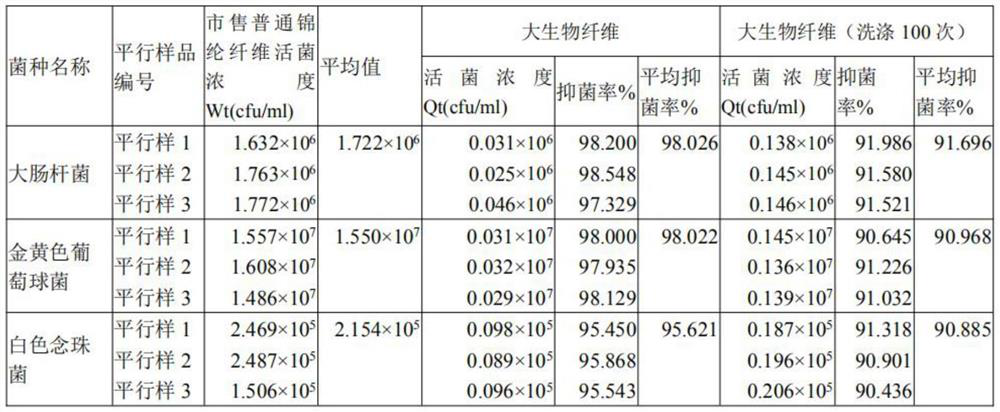

Examples

Embodiment 1

[0040] Embodiment 1: concrete steps are as follows:

[0041] S100, preparation of coffee extract:

[0042] S110. Put 100g of pre-ground coffee beans into the extraction kettle, heat the extraction kettle, the first separation kettle and the second separation kettle, the extraction temperature is 48°C, the temperature of the first separation kettle is 48°C, and the second separation kettle is heated. The temperature of the second separation tank is 43°C,

[0043] S120. When the temperature reaches the requirement, pass CO to the extraction tank, the first separation tank, and the second separation tank. 2 Boosting, extraction pressure 25MPa, first separation tank pressure 6MPa, second separation tank pressure 6MPa,

[0044] S130. When the pressure reaches the requirement, start circular extraction, keep constant temperature and pressure, and add 80% ethanol as entrainer at the same time, the addition of 80% ethanol is 500m L / (100g material), extraction time is 3.5h, CO 2 The...

Embodiment 2

[0058] Embodiment 2: concrete steps are as follows:

[0059] S100, preparation of coffee extract:

[0060] S110. Put 100g of pre-ground coffee beans into the extraction kettle, heat the extraction kettle, the first separation kettle and the second separation kettle, the extraction temperature is 48°C, the temperature of the first separation kettle is 48°C, and the second separation kettle is heated. The temperature of the second separation tank is 43°C,

[0061] S120. When the temperature reaches the requirement, pass CO to the extraction tank, the first separation tank, and the second separation tank. 2 Boosting, extraction pressure 25MPa, first separation tank pressure 6MPa, second separation tank pressure 6MPa,

[0062] S130. When the pressure reaches the requirement, start circular extraction, keep constant temperature and pressure, and add 80% ethanol as entrainer at the same time, the addition of 80% ethanol is 500m L / (100g material), extraction time is 3.5h, CO 2 The...

Embodiment 3

[0075] Embodiment 3: concrete steps are as follows:

[0076] S100, preparation of coffee extract:

[0077] S110. Put 100g of pre-ground coffee beans into the extraction kettle, heat the extraction kettle, the first separation kettle and the second separation kettle, the extraction temperature is 48°C, the temperature of the first separation kettle is 48°C, and the second separation kettle is heated. The temperature of the second separation tank is 43°C,

[0078] S120. When the temperature reaches the requirement, pass CO to the extraction tank, the first separation tank, and the second separation tank. 2 Boosting, extraction pressure 20MPa, first separation tank pressure 4MPa, second separation tank pressure 4MPa,

[0079] S130. When the pressure reaches the requirement, start cyclic extraction, keep constant temperature and pressure, and add 80% ethanol as an entrainer at the same time, the amount of 80% ethanol added is 350m L / (100g material), the extraction time is 2h, CO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com