Cleaning composition and process capable of effectively removing scale and low in corrosivity

A cleaning composition and a corrosive technology, applied in the field of cleaning compositions, can solve the problems of secondary rust; sulfamic acid is stable at room temperature, non-volatile, non-hygroscopic, damaged, low in cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

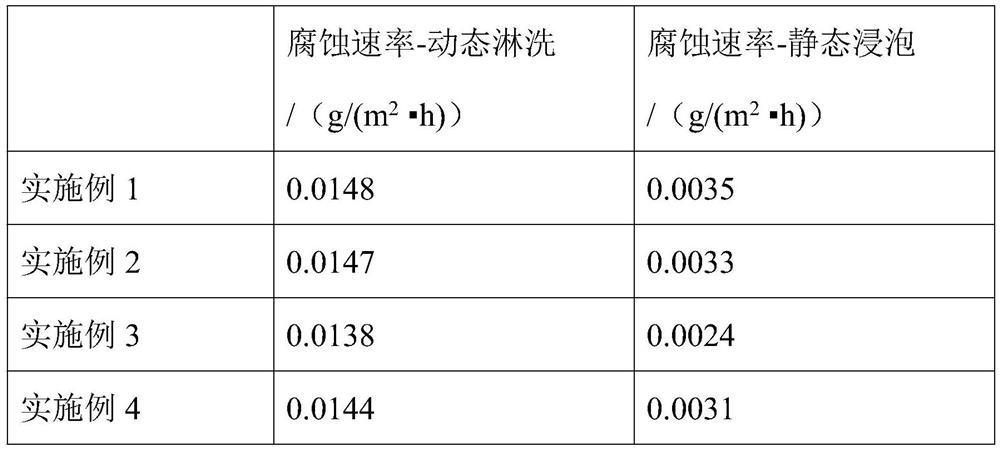

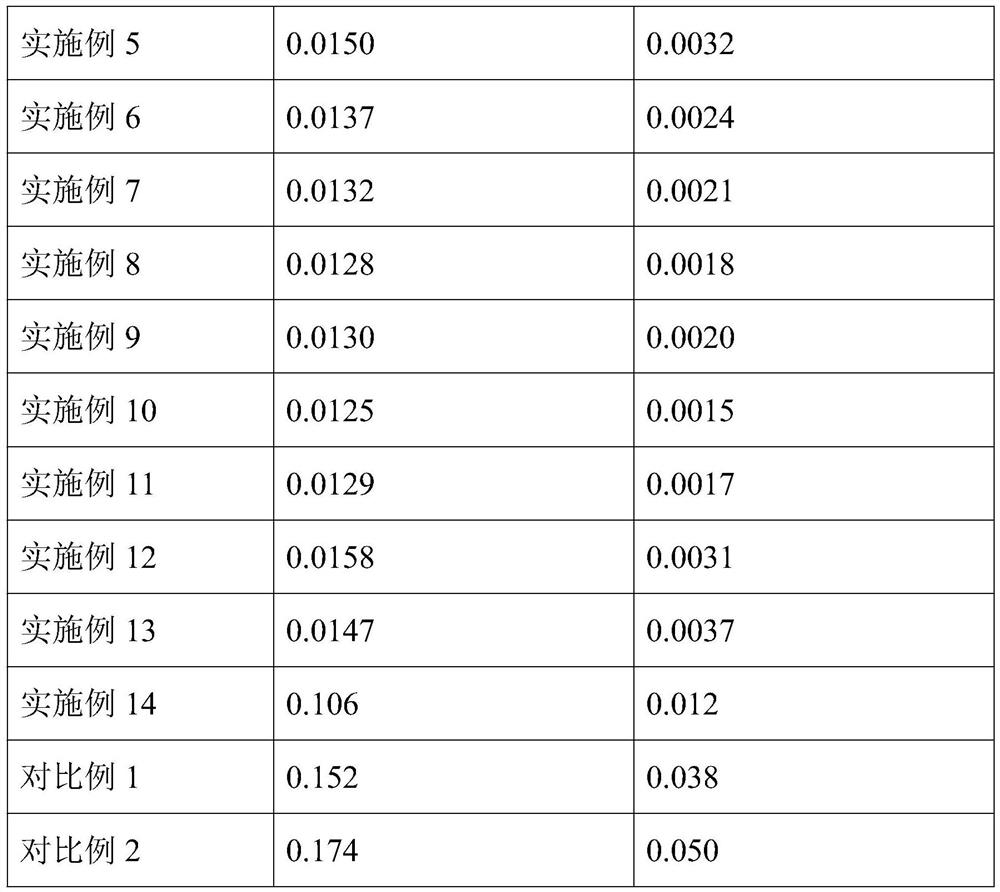

Examples

Embodiment 1

[0036] A cleaning composition having a low corrosive corrosive, comprising 2.0 kg of inorganic acid, 0.8 kg of corrosion inhibitor, 0.03 kg of surfactant, 3.6 kg of ethanol, and 93.57 kg of water.

[0037] Among them, the inorganic acid is amino sulfonic acid;

[0038] Corrosion inhibitors include imidazoline quaternine salts, benzotriazole, thiazole, and imidazoline quaternine salts, benzotriazole, thiazole weight ratio of 1: 0.3: 0.6;

[0039] The surfactant is OP-15.

[0040] A cleaning process that can be effective descant and low corrosive, including the following steps:

[0041] First, the corrosion inhibitor, surfactant is dissolved in ethanol to obtain a dissolved liquid, and then mix the dissolved liquid and water and extrapolate the cycle in the system to be cleaned, and finally pose the inorganic acid into the system to be cleaned. Until the scale is cleared.

Embodiment 2

[0043] The difference from Example 1 is:

[0044] A cleaning composition having a lower corrosive corrosive, comprising the following components: 3.0 kg of inorganic acid, 0.5 kg of corrosion inhibitor, 0.04 kg of surfactant, 2.6 kg of ethanol, and 93.86 kg of water.

Embodiment 3

[0046] The difference from Example 1 is:

[0047] A cleaning composition having a lower corrosive corrosive, including 4 kg, corrosion inhibitor 0.3 kg, surfactant 0.05 kg, and 1.4 kg of ethanol, water 94.25 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com