FOF scale inhibition material filtering device for direct drinking water purifier and use method thereof

A technology of drinking water purifier and filtering device, which is applied in the direction of chemical instruments and methods, filtering treatment, mixer with rotating stirring device, etc., which can solve the problems of high cost, troublesome cleaning, harm to drinkers, etc., and achieve cost saving , reduce the generation of scale, and ensure the effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

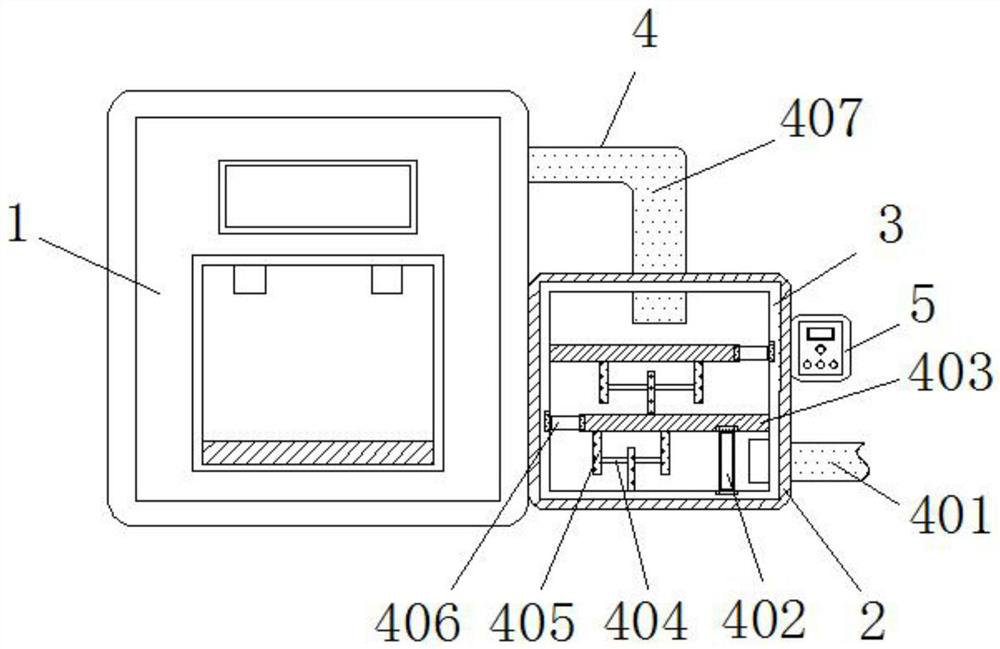

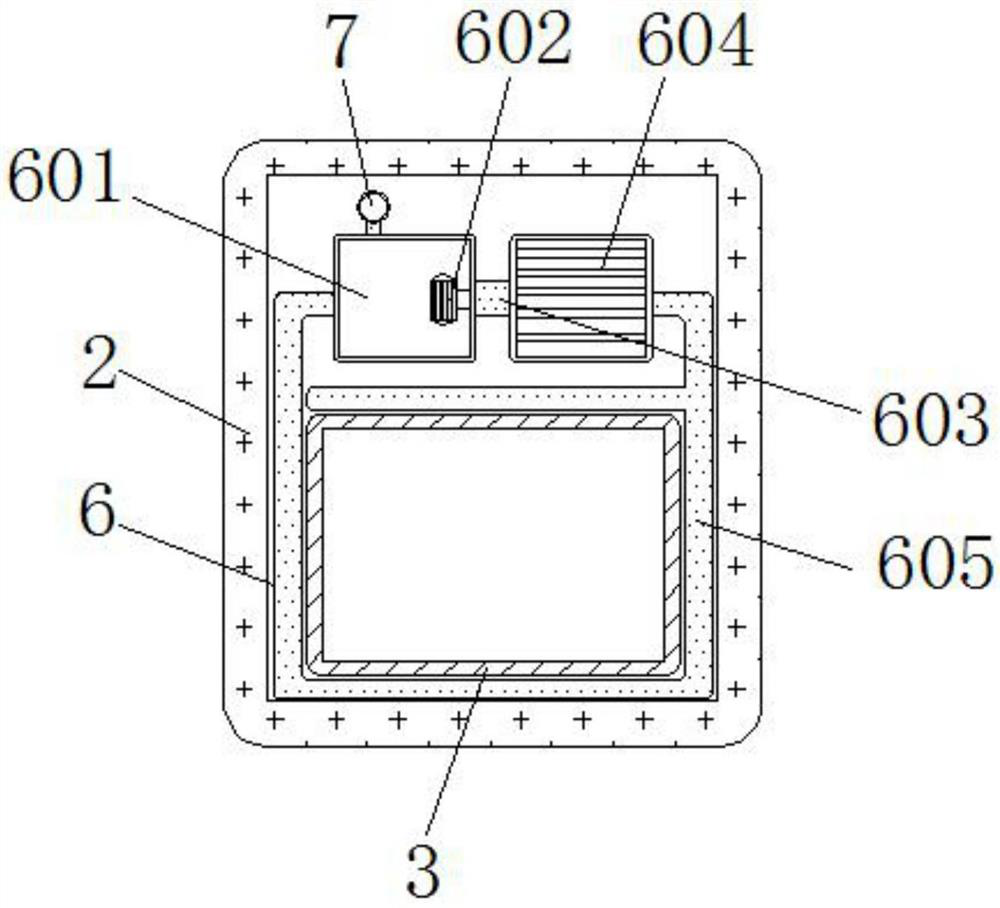

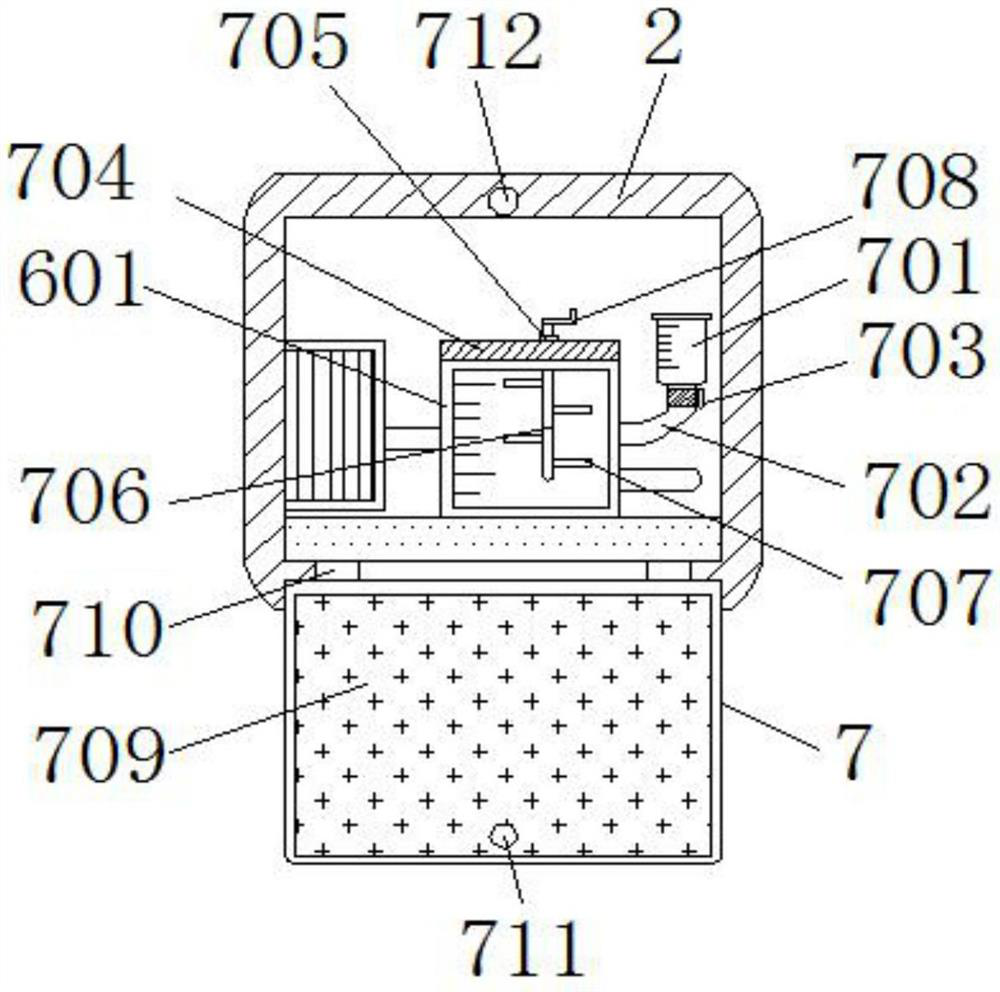

[0036] Such as Figure 1-Figure 5 As shown, a FOF scale-inhibiting material filter device for direct drinking water purifiers includes a drinking water body 1, a filter body 2, an inner box 3, a filter mechanism 4, a water inlet pipe 401, a preliminary filter layer 402, and a layered plate 403 , FOF filter element filter layer 404, partition 405, high-efficiency filter layer 406, outlet pipe 407, control device 5, constant temperature mechanism 6, water tank 601, water pump 602, first connecting pipe 603, heater 604, heating pipe 605, opening and closing Mixing mechanism 7, scale cup 701, diversion tube 702, regulating valve 703, cover plate 704, movable shaft 705, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com