Electronic electroplating wastewater recycling advanced treatment technology

A technology for advanced treatment of electroplating wastewater, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficulty in selecting functional bacteria, high cost of chemicals, and few examples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: An advanced treatment process for reuse of electronic electroplating wastewater

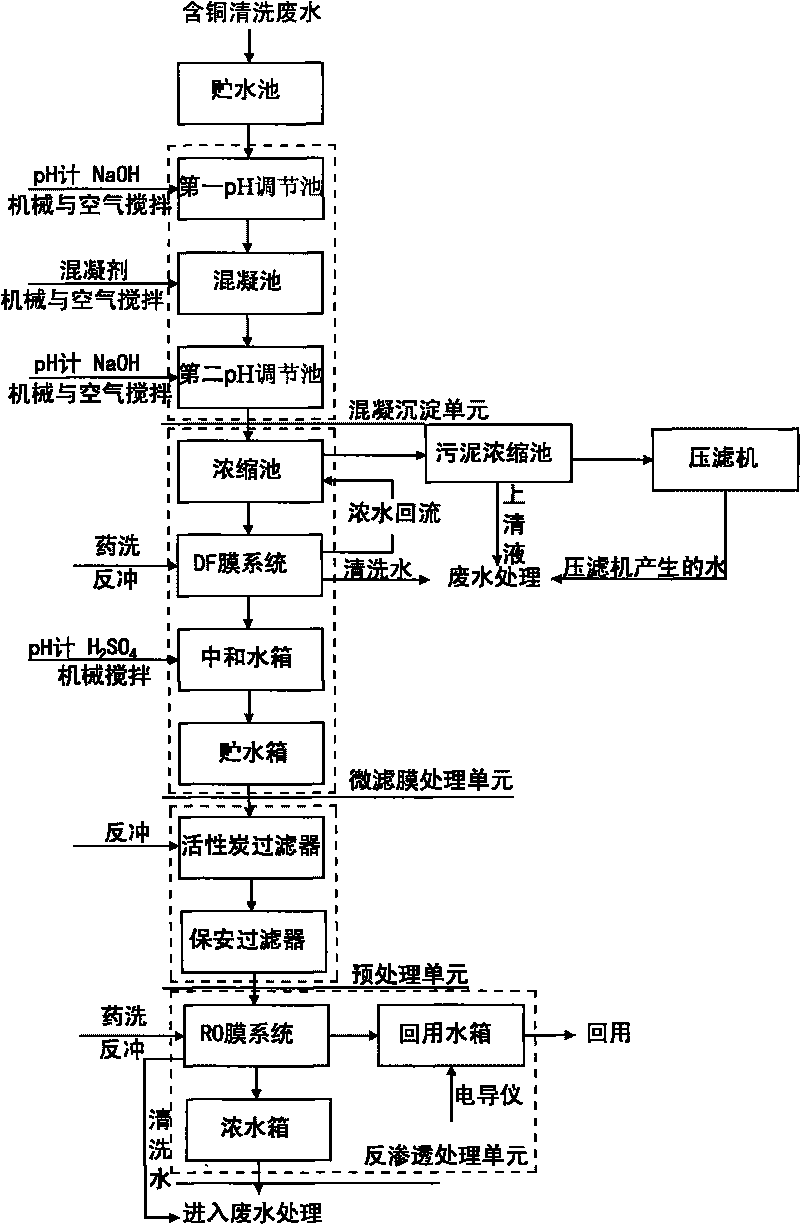

[0034] The technological process of this technical scheme is as attached figure 1 shown.

[0035] Taking copper-containing cleaning wastewater generated in the production process of printed circuit board (PCB) enterprises as an example, advanced wastewater treatment and reuse are carried out.

[0036] (1) pH adjustment + microfiltration membrane treatment system

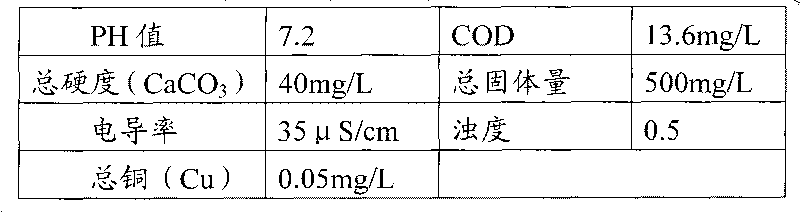

[0037] Taking the copper-containing cleaning wastewater generated by PCB enterprises as the treatment object, after the wastewater is discharged into the storage tank, the raw water quality monitoring structure is as follows: the pH value of the wastewater is 4.5, the COD is 173mg / l, and the Cu is 136mg / l. First, pump the cleaning wastewater to the first pH adjustment tank, add sodium hydroxide to the first pH adjustment tank to control the pH value at about 9-10, then pump the wastewater to the coagulation tank, ...

Embodiment 2

[0047] Example 2: An advanced treatment process for reuse of electronic electroplating wastewater

[0048] One, process flow chart copper embodiment one

[0049] Electroplating wastewater for the following water quality indicators:

[0050] (1) The chemical oxygen demand is 184mg / l;

[0051] (2) The copper content is 127mg / l, and the nickel content is 0.5mg / l;

[0052] (3) Conductivity less than or equal to 2400μs / cm;

[0053] Take the following steps to process:

[0054] The first step: adjust the pH value of the treated electronic electroplating wastewater to 9.7, then add a coagulant to it and stir, so that the metal ions in the electronic electroplating wastewater react to form metal hydroxides and then precipitate; after adding the coagulant And the pH value is maintained at 9-10 during the stirring process; the coagulant is ferric chloride.

[0055] The second step: using the microfiltration membrane to process the treatment liquid obtained in the first step under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com