A biological hydrogen production device

A technology of biological hydrogen production and vertical installation, which is applied in biochemical cleaning devices, enzymology/microbiology devices, biomass post-processing, etc., can solve the problems of inability to guarantee the crushing accuracy of substrates, affecting the rate and effect of fermentation, etc. Achieve the effect of increasing the screening efficiency, improving the crushing efficiency and ensuring the uniformity of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The following description is used to disclose the invention to enable those skilled in the art. The preferred embodiments in the following description are only example, and those skilled in the art can think of other obvious variations.

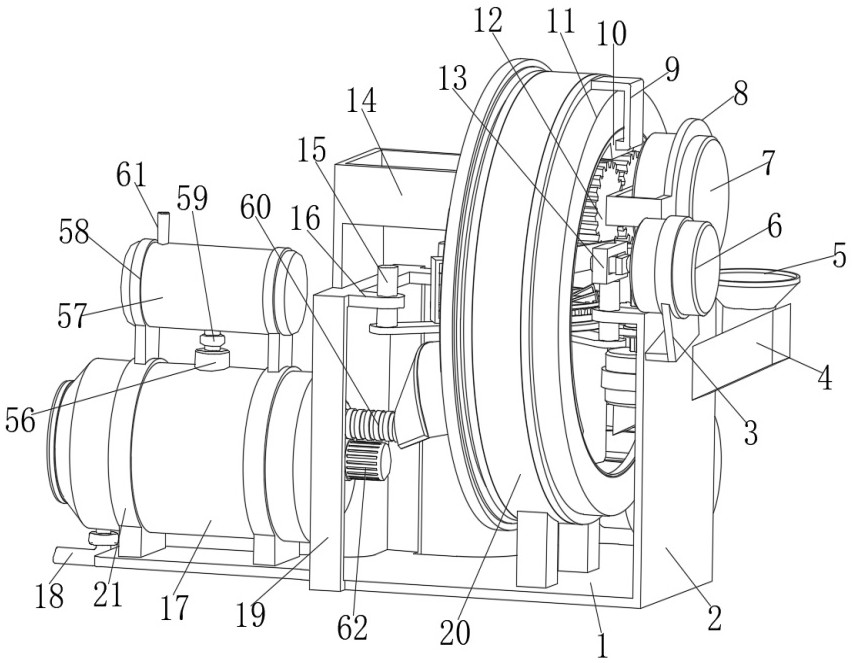

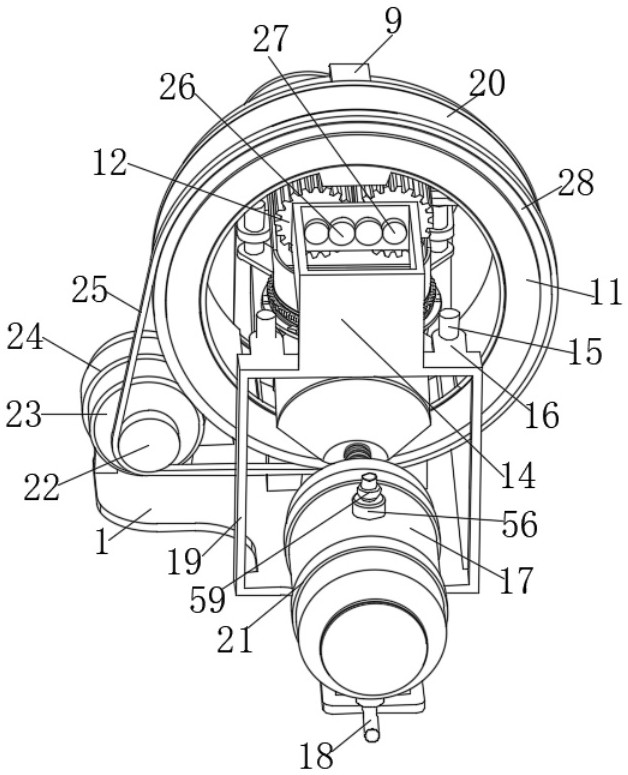

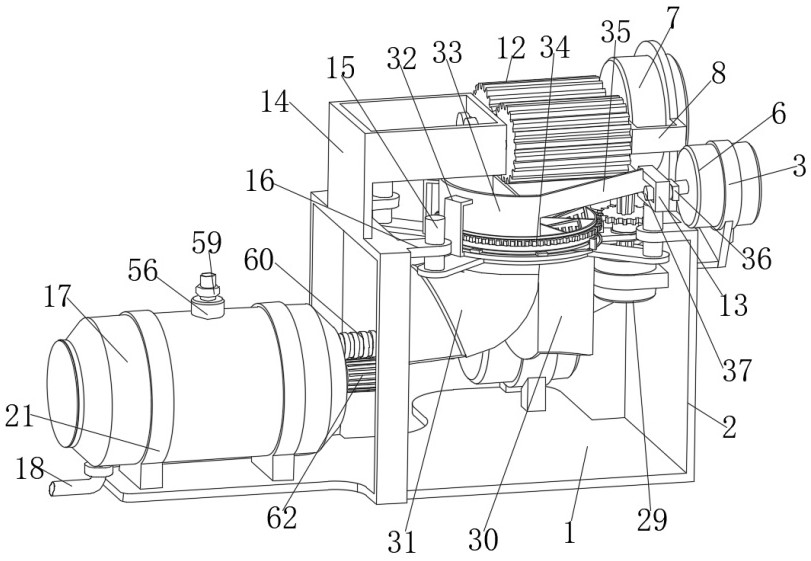

[0029] like Figure 1 - Figure 11 A biological hydrogen supply device, including the lateral bottom plate 1, and the top of the lateral bottom plate 1 is vertically mounted with longitudinal plate 2, and the top of the longitudinal plate 2 is provided with a niche, and the other end of the top of the lateral bottom plate 1 is vertically mounted. The support frame 19, and the lower support frame 19 is connected between the top end of the longitudinal plate 2, and the screening mechanism includes a screening mechanism including a horizontally disposed screening ring 46, and the internal intermediate position of the screening ring cover 46 is provided with a central column. 50, the outer side of the center post 50 and the inner wall of the siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com