Preparation method of bio-based self-repairing polyurethane elastomer

A technology of polyurethane elastomer and polyurethane prepolymer is applied in the field of preparation of bio-based self-healing polyurethane elastomer, which can solve the problems of inability to further use, damage of polyurethane, non-renewable, etc., and achieve good self-healing performance and mild preparation process conditions. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

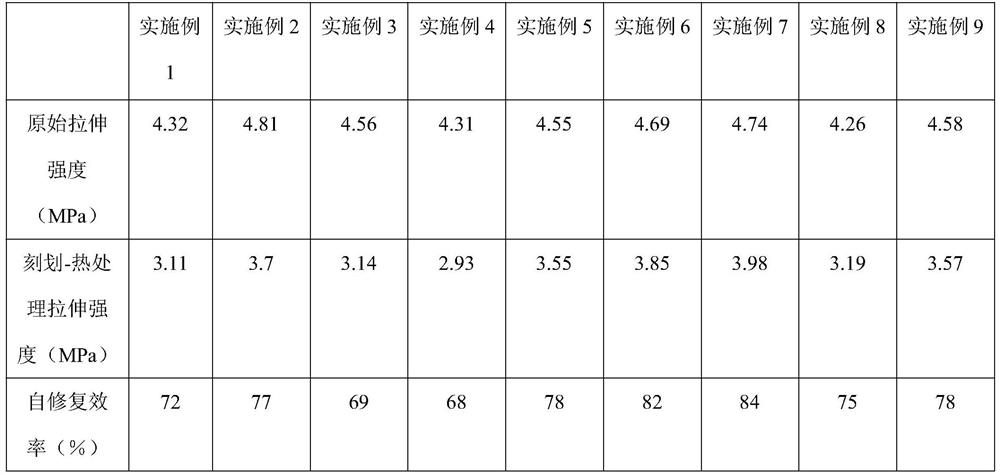

Examples

preparation example Construction

[0027] A preparation method of bio-based self-healing polyurethane elastomer, furfurylamine and formaldehyde undergo condensation reaction in the presence of hydrochloric acid, and then undergo aldolamine condensation with vanillin to obtain a small molecule chain extender containing dynamic imine bonds, and then Chain extension reaction with polyurethane prepolymer made of diphenylmethane diisocyanate (MDI-50) and polypropylene glycol (PPG), after vacuum degassing, pour the obtained solution into a preheated polytetrafluoroethylene mold , heating at 40-80°C for 12-30 hours to obtain a polyurethane elastomer.

[0028] Described chain extender synthetic steps are as follows:

[0029] (1) Preparation of Difurfurylamine: Add furfurylamine into a flask with a reflux condenser, cool to -5-5°C, add hydrochloric acid with a mass fraction of 10-40%, heat up to 10-30°C and stir. Add a part of acetone, raise the temperature to 10-50°C, and then add the remaining acetone to continue the...

Embodiment 1

[0034] Described chain extender synthetic steps are as follows:

[0035] (1) Preparation of bisfurfurylamine: add 0.2mol of furfurylamine into a flask with a reflux condenser, cool to -5°C, add 10% hydrochloric acid (0.6mol), heat up to 10°C and stir. 0.13 mol of acetone was added, the temperature was raised to 10° C., and the remaining 0.07 mol of acetone was added to continue the reaction for 2 days. After the mixture was cooled, 50ml of water was added, and the pH was adjusted to 8 with a 10wt% sodium hydroxide solution. After extraction with tetrahydrofuran, the organic phase was washed with saline, dried and rotary evaporated to obtain the product DFA.

[0036] (2) Preparation of chain extender: After dissolving 0.2 mol of vanillin, add a solution of bisfurfurylamine (0.1 mol) in dichloromethane dropwise, heat to 30°C for 20 min, spin evaporate, and vacuum dry to obtain chain extender VDFA.

[0037] Add 0.072 mol of diphenylmethane diisocyanate (MDI) to 0.04 mol of polyp...

Embodiment 2

[0039] (1) Preparation of bisfurfurylamine: add 0.2mol of furfurylamine into a flask with a reflux condenser, cool to 5°C, add 10% hydrochloric acid (0.6mol), heat up to 10°C and stir. 0.13 mol of acetone was added, the temperature was raised to 50° C., and the remaining 0.07 mol of acetone was added to continue the reaction for 5 days. After the mixture was cooled, 50 ml of water was added, and the pH was adjusted to 8 using a sodium hydroxide solution with a mass fraction of 10 wt%, and the organic phase was extracted with dichloromethane, washed with saline, dried and rotary evaporated to obtain the product DFA;

[0040] (2) Preparation of chain extender: After 0.2 mol of vanillin was dissolved, a DMF solution of bisfurfurylamine (0.1 mol) was added dropwise, heated to 70°C for 70 min, rotary evaporated, and vacuum dried to obtain chain extender VDFA.

[0041] Add 0.072mol of diphenylmethane diisocyanate (MDI) to 0.04mol of polypropylene glycol with a molecular weight of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com