High swing data line and preparation method thereof

A technology for data lines and transmission lines, applied in the field of high-swing data lines and their preparation, can solve the problems of abnormal use of data lines, high rigidity, cracking, etc., and achieve the effect of improving the promotion effect, reducing wrinkles, and reducing fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

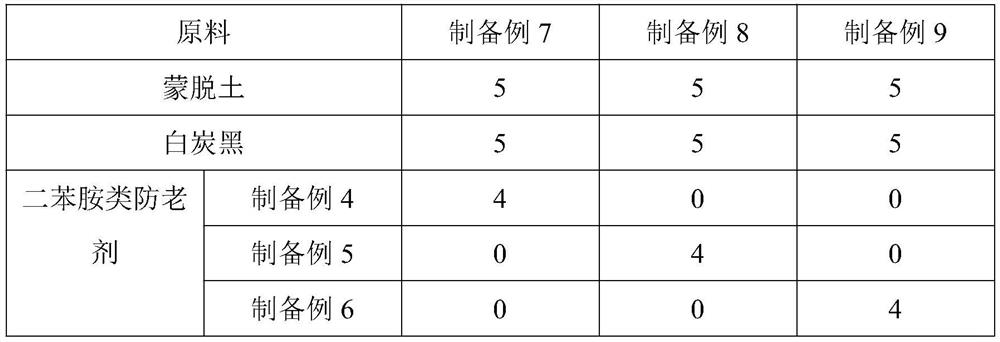

[0044] As shown in Table 1, the main difference of Preparation Examples 1-3 is that the raw materials are different.

[0045] The following takes Preparation Example 1 as an example for illustration.

[0046] A kind of grafting aid, adopt following steps to prepare: According to proportioning, put dialkyl peroxide initiator and caprolactam into agitator, under the stirring speed of 160r / min, stir 5min, obtain grafting aid .

[0047] Table 1 Raw material ratio of grafting aids

[0048]

preparation example 4

[0050] A kind of diphenylamine anti-aging agent, adopts following steps to prepare:

[0051] S1. According to the proportioning ratio, add 12.5kg of 4-aminodiphenylamine, 50kg of methyl isoamyl ketone and 0.65kg of Pd / C catalyst into the reactor in sequence, and stir for 10min at 140r / min to obtain a mixture;

[0052] S2, feed nitrogen into the reactor for 2 minutes, then feed hydrogen for 2 minutes, adjust the air pressure in the reactor to 3.5 MPa, then raise the temperature of the reactor to 140° C., and keep the temperature and pressure for 3 hours to obtain the reaction product;

[0053] S3, filter the reaction product, remove the Pd / C catalyst in the reaction product, obtain the filtrate, distill the filtrate at 100°C, stop the distillation when the mass fraction of the filtrate is 98.5%, and obtain the diphenylamine anti-aging agent.

preparation example 5

[0055] The difference between this preparation example and preparation example 4 is that in the step S2, the temperature of the reaction kettle is raised to 160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com