Shield tunneling machine steel pipe mounting and lifting device

A lifting device, shield machine technology, applied in the direction of crane, transportation and packaging, load hanging components, etc., can solve the problems of unstable clamping, difficult to install steel pipes, etc., to improve the use effect, strong adaptability, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

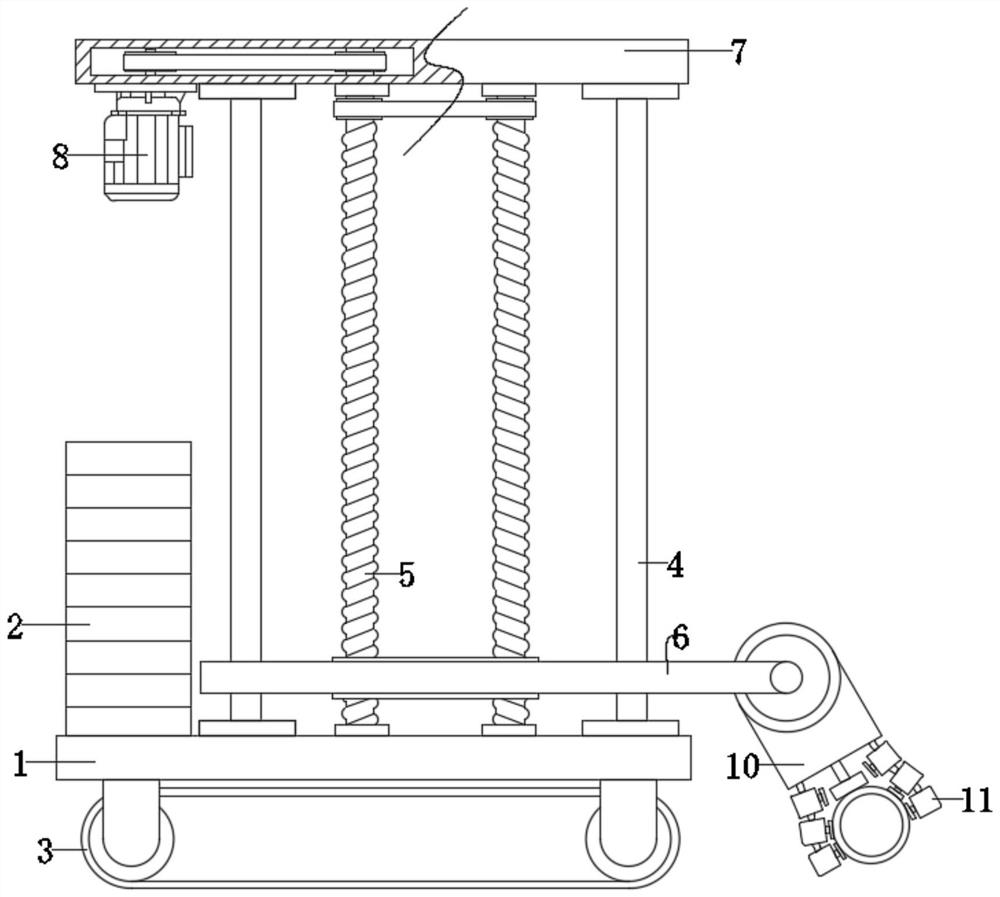

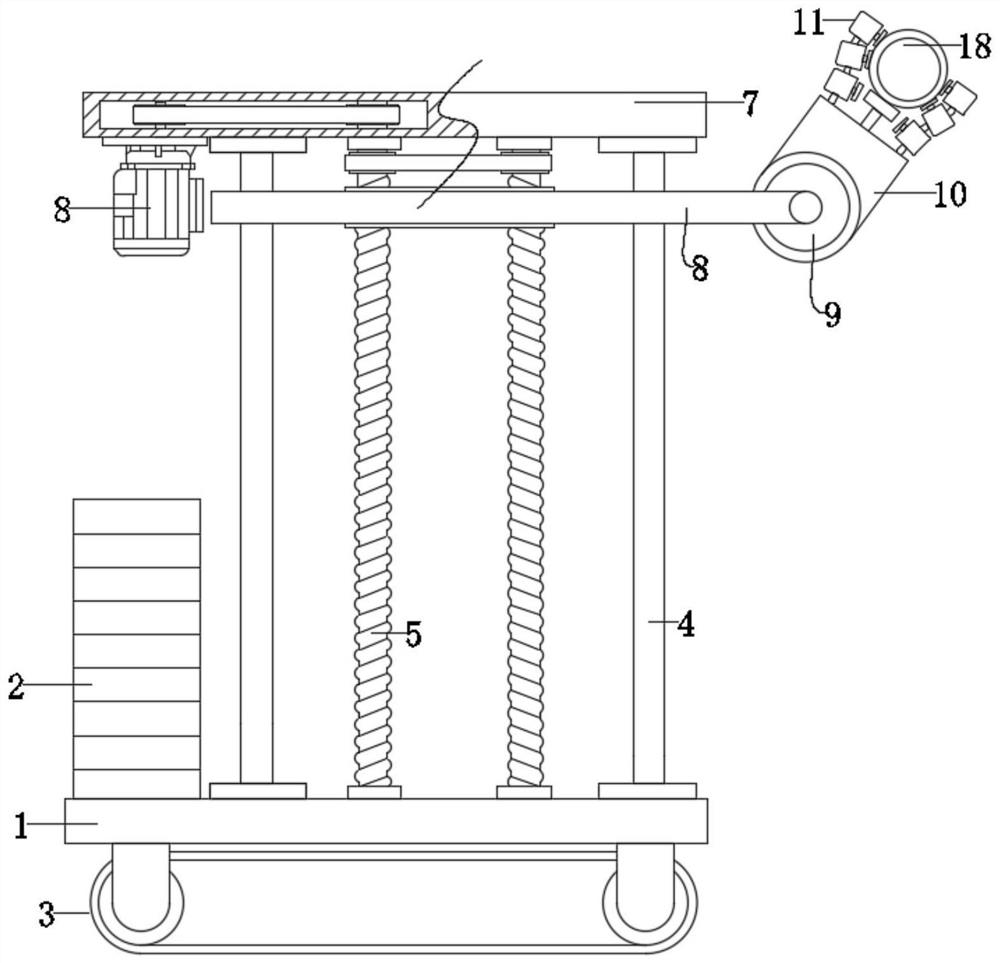

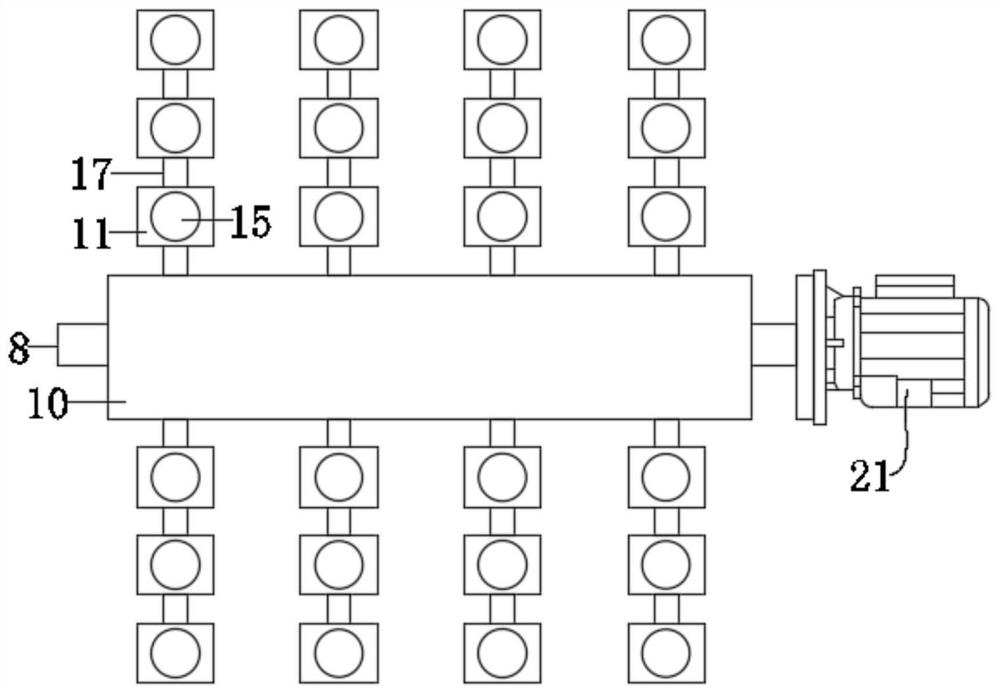

[0027] see Figure 1-3 , a steel pipe installation lifting device for a shield machine, including a bottom plate 1, an upper plate 7 and a lifting assembly, wherein a guide rod 4 is fixedly connected to the bottom plate 1, and several groups of guide rods 4 are installed on the bottom plate 1. The plate 7 is fixedly connected to the guide rod 4, and the lifting assembly is arranged and installed between the bottom plate 1 and the upper plate 7. The clamping assembly is connected and installed on the lifting assembly, and the steel pipe 18 is clamped on the clamping assembly, and the steel pipe 18 clamps Installed on the clamping assembly, the lift is performed by the lifting assembly; further, the clamping assembly includes a clamping seat 10, a clamping block 11 and an adsorption assembly, and the adsorption assembly is arranged on the clamping block 11 , the steel pipe 18 is effectively adsorbed by the adsorption assembly; the clamping block 11 is installed on the clamping s...

Embodiment 2

[0034] In this embodiment, the following improvements are made on the basis of the above embodiments, wherein a transfer assembly is arranged and installed on the base plate 1, and the transfer assembly includes rollers and crawlers 3, and the rollers are rotatably mounted on the base plate 1 and the The crawler belt 3 is swelled and installed on the rollers, and a power unit is connected to the rollers. The power unit drives the rollers to rotate, and the stability of the device during the transfer process is greatly improved under the action of the crawler belts 3 .

[0035]The working principle of the present invention is: during the use of the device, the adjacent clamping blocks 11 are hinged through the connecting rod 17, so that the clamping blocks 11 of a single group have certain flexibility and can adapt to different Diameter steel pipe 18; when the adsorption component on the clamping block 11 is adsorbed on the steel pipe 18, the piston rod of the telescopic rod 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com