Double-thread winding high-voltage wire package production line

A production line and high-voltage line technology, applied in transportation and packaging, thin material handling, conveyor objects, etc., can solve the problems of labor consumption and low manufacturing effect, and achieve the effect of improving production effect, reasonable design and ingenious conception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

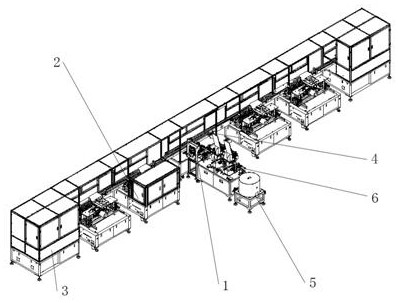

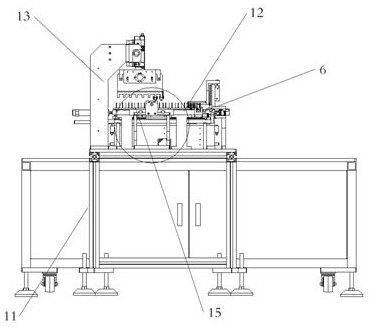

[0058] like Figure 1-19 As shown, a double-thread winding high-voltage wire package production line, the production line includes a feeding device 1, a winding device 2, a loading device 3 and a handling device 4; the loading device 1 is one, and the loading device 3 is two. 1, the loading device 3 is installed on the left and right sides of the loading device 1, one or more winding devices 2 are installed between the loading device 1 and the loading device 3 in turn. 2. The loading device 3 is arranged in a line and is connected by the handling device 4. The loading device 1 and the winding device 2 on the left side and the loading device 3 together form the left thread, and the loading device 1 and the winding device on the right side together form the left thread. The device 2 and the loading device 3 together form the right thread; the double-thread winding high-voltage wire package production line also includes a vibrating disc 5; 1.

[0059] The feeding device 1 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com