Full-automatic 4U lamp tube bridging apparatus and its process

A fully automatic, bridge equipment technology, applied in glass manufacturing equipment, manufacturing tools, glass molding and other directions, can solve the problems of not adapting to the manufacturer's automatic production line, unable to meet mass production, inconsistent product specifications and standards, etc. The effect of improving equipment utilization, improving quality, and unifying product specifications and standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

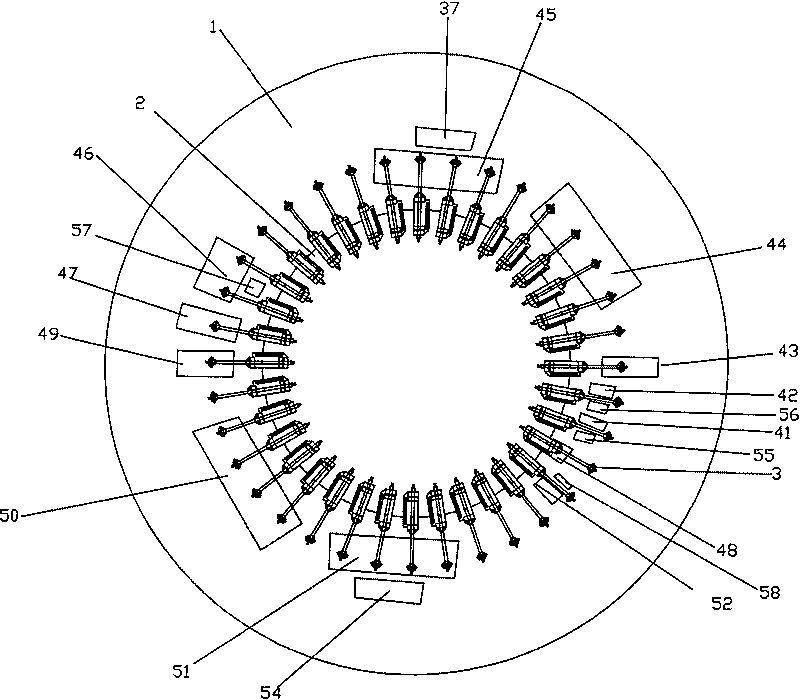

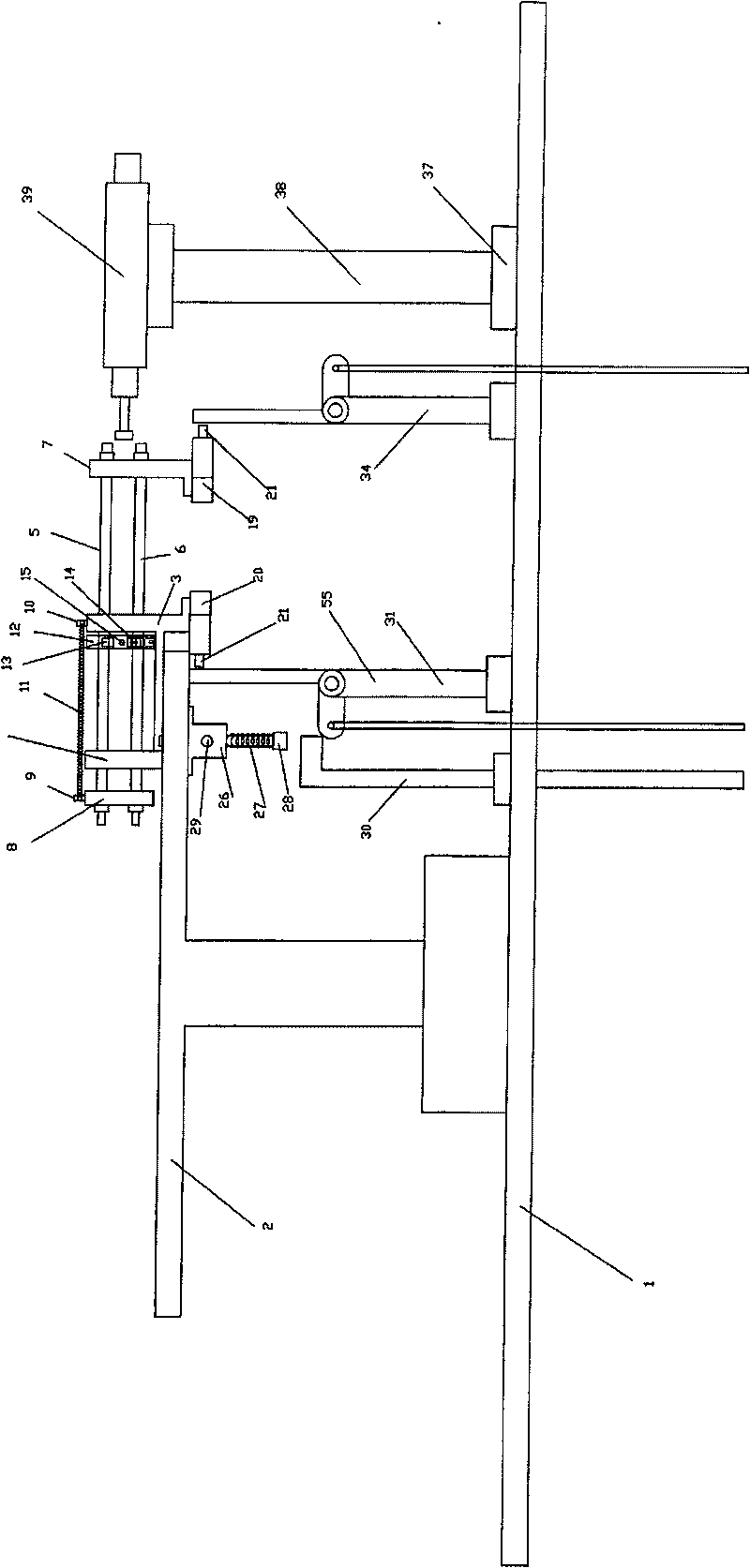

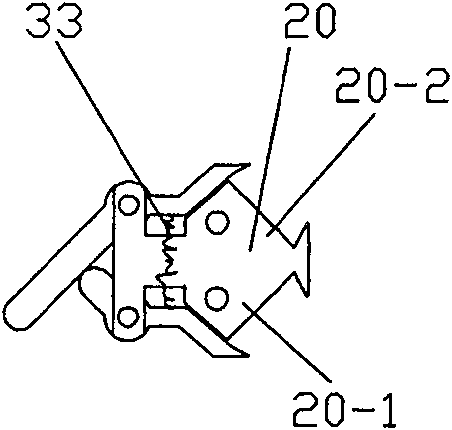

[0034] Such as Figures 1 to 9 As shown, this embodiment is composed of a working machine table 1 and a turntable table 2. The turntable table 2 is arranged on the working machine table 1. The turntable table 2 can rotate in situ on the working machine table 1. 36 head devices 3, on the working machine table 1 and around the turntable table 2, there are successively distributed a primary lifting device 48, a primary tube loading device 41, a secondary tube loading device 42, a sheet tube positioning device 43, and a primary flattening device 44. Primary bridging device 45, overturning device 46, first bridge, second bridge positioning device 47, secondary push-off device 49, flat head device 50, secondary bridging device 51 and lower tube device 52, in the primary upper tube device 41. The secondary upper pipe device 42, the turning device 46 and the lower pipe device 52 are respectively provided with a primary unclamping device 55, a secondary unclamping device 56, a third un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com