A high-efficiency battery missing ring steel shell ring repair device

A battery and high-efficiency technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as difficult alignment, low operating efficiency, and difficult quality assurance, and achieve the effects of preventing offset, easy insertion and removal, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

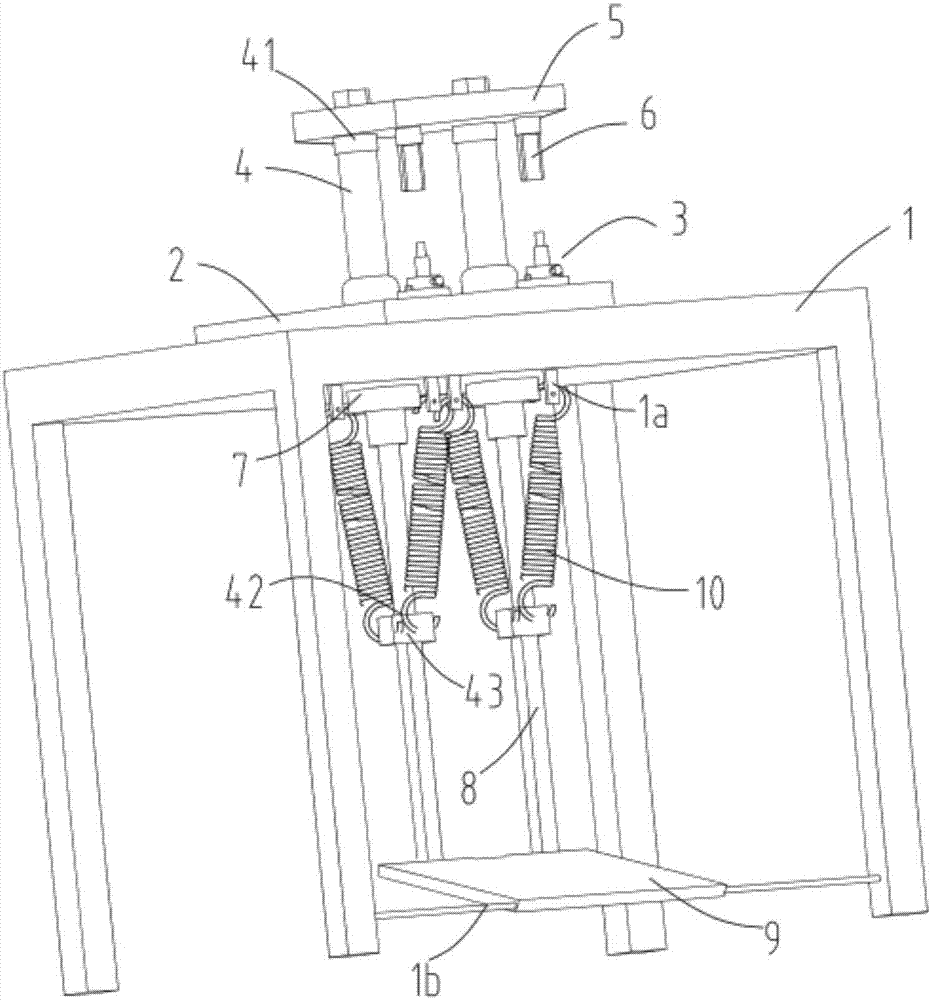

[0024] figure 1 It is a structural schematic diagram of a high-efficiency battery missing ring steel shell repairing device, figure 2 It is a structural schematic diagram of the ring fixing device of a high-efficiency battery missing ring steel shell ring repairing device. Such as figure 1 , figure 2 As shown, a high-efficiency battery missing ring steel shell repairing device includes a base 2 arranged on a workbench 1, and a ring fixing device 3 and a telescopic rod 4 are sequentially arranged on the base 2 from front to back; the ring fixing The device 3 and the telescopic rod 4 are provided with at least two groups; the upper end 41 of the telescopic rod 4 is provided with a fixed plate 5; the fixed plate 5 is provided with at least two ring-fixed devices corresponding to at least two groups of ring-fixed devices 3 3 coaxial steel shell slots 6 in the vertical direction; at least two sliding sleeves 7 matching with the telescopic rods 4 are provided on the base 2 corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com