Curved surface five-axis cutting equipment used for PEEK material machining and control system of curved surface five-axis cutting equipment

A material processing and cutting equipment technology, applied in the cleaning method using tools, metal processing, and cleaning methods using gas flow, etc., can solve the problems of small clamping surface, unstable clamping, and falling off of cylindrical materials, and achieve Effect of increasing clamping area, maintaining cleanliness, and increasing clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

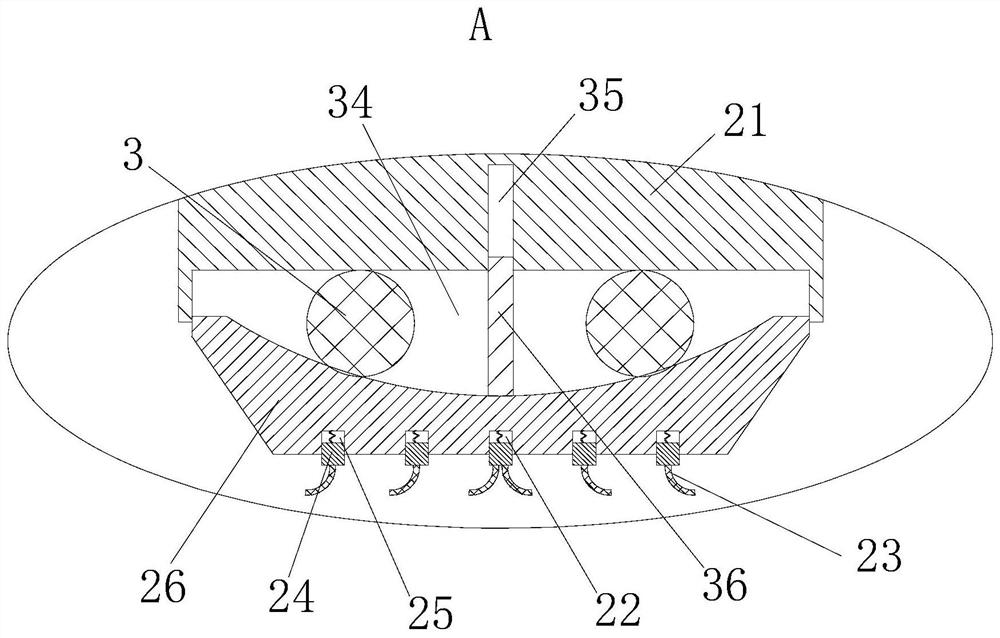

[0039] As an embodiment of the present invention, the arc-shaped pressing strip 23 is provided with a first cavity 31, and the outer wall of the arc-shaped pressing strip 23 away from the clamping surface of the claw 21 is provided with an air outlet 32, And the air outlet 32 and the first cavity 31 communicate with each other; the clamping surface of the claw 21 is provided with a third groove 34; plate 26, and the pressing plate 26 is slidably connected on the side wall of the third groove 34; the third groove 34 is opened on the outer side wall of the pressing plate 26; the first air bag 3 passes through the hose and the The first cavities 31 communicate with each other; during work, when the jaws 21 move and clamp the cylindrical workpiece, they will contact the pressing plate 26 earlier, and then continue to push the jaws 21, and the pressing plate 26 will move toward The bottom of the third groove 34 moves, and the first air bag 3 will be squeezed during the movement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com