Method for supplementing water to dilute concentrated solution of salt lake brine

A salt lake brine and concentrated solution technology, applied in separation methods, mixing methods, chemical instruments and methods, etc., can solve the problems of low output of diluent and slow liquid return speed of concentrated solution, and achieve uniform concentration, conductivity value and pH The effect of stabilizing and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0138] Hereinafter, the present invention will be described in detail with reference to Examples. However, the embodiments of the present invention may be modified into various other forms, and the scope of the present invention should not be construed as being limited to the embodiments described below. The embodiments of the present invention are provided so as to more fully describe the present invention to those skilled in the art.

[0139] If the experimental methods in the following examples do not indicate specific conditions, they are usually the conventional conditions in this field or the conditions suggested by the manufacturer; the raw materials and equipment used, if no special instructions, are available from commercial channels such as the conventional market Raw materials and equipment obtained.

Embodiment 1

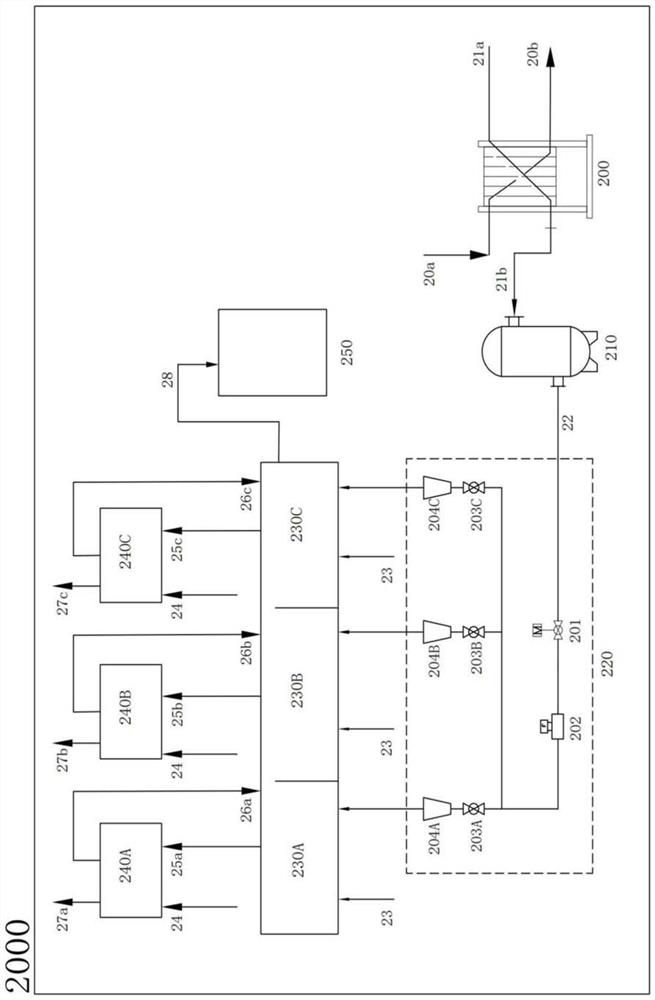

[0151] refer to figure 2 , compared with the prior art single make-up water dilution system in Comparative Example 1, in the multi-stage make-up water dilution system of the present embodiment, a heating mechanism 200 is additionally added, and a new control mechanism 220 is used, wherein the dilution tank 230A , 230B, and 230C are all diluted with water, and the water intake of the dilution tanks 230A, 230B, and 230C is distributed in a gradually decreasing manner, and the raw water replenishment at the top of the storage mechanism 250 is canceled.

[0152] The workflow of this embodiment is as follows.

[0153] First, the raw water 21a (50.00m 3 / h, 15°C) to the plate heat exchanger as the heating mechanism 200 (from Alfa Laval (Shanghai) Technology Co., Ltd., the material is TA), and at the same time, 120°C from the gas supply facility is passed into the plate heat exchanger The steam 20a (1m 3 / h) to heat raw water 21a to obtain heated water 21b whose temperature is 33...

experiment example 1

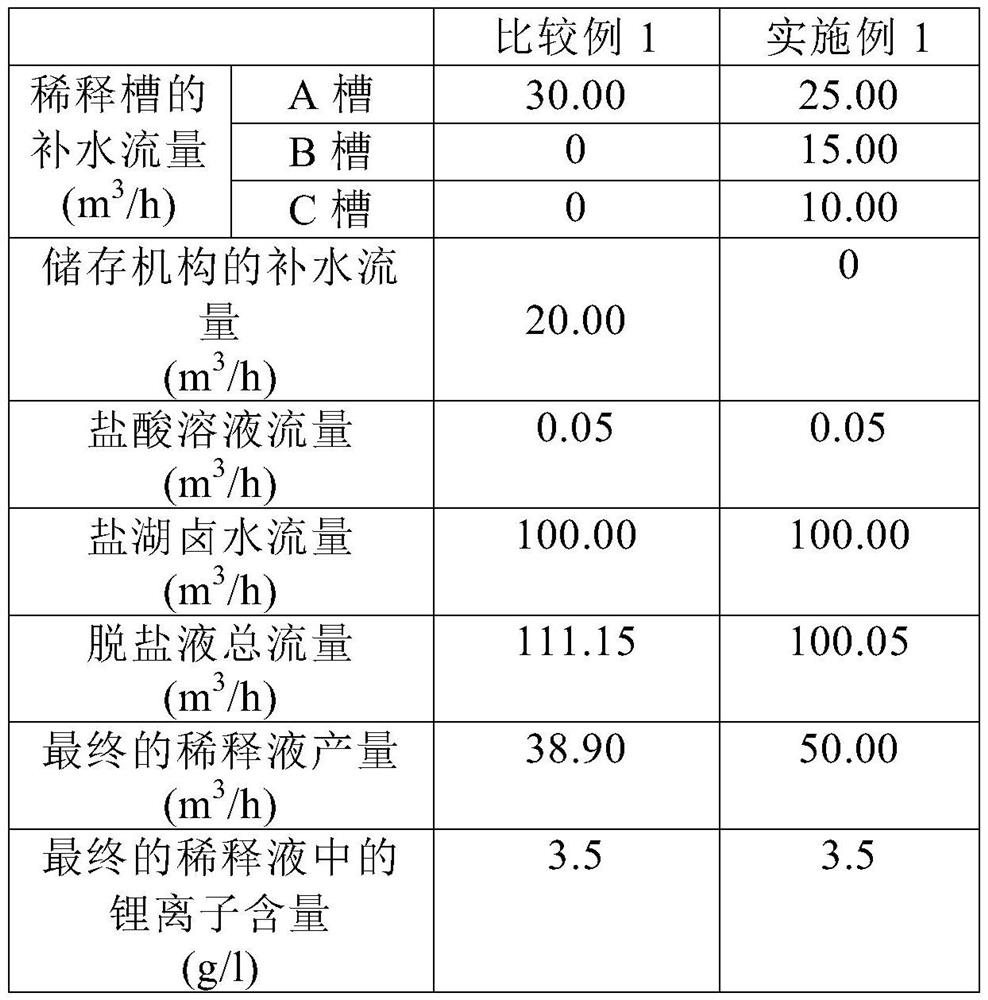

[0165] Through the feedback data provided by DCS (Zhejiang University Central Control Program Control System), the operation of each mechanism and device in Comparative Example 1 and Example 1 is controlled, and various data are obtained by measurement, which are summarized in Table 1 below.

[0166] Table 1

[0167]

[0168] As can be seen from Table 1, when the total amount of water added, the flow of hydrochloric acid solution and the flow of salt lake brine added are all the same respectively, compared with Comparative Example 1, the final dilution of Example 1 significantly improves the output. And have the same lithium ion content. This fully demonstrates that the multi-stage replenishment dilution method of the present invention can significantly increase the output of diluent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com