A pulse balloon and its application

A balloon and pulse technology, applied in the field of medical devices, can solve problems such as heart rate interference, achieve the effect of improving the degree of integration, increasing the service life, and avoiding separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

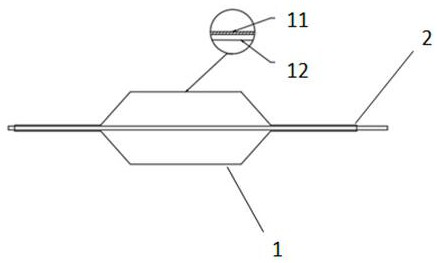

[0058] Such as figure 1 As shown, the present embodiment provides a pulse balloon, which includes a balloon body 1 and an inner tube 2; the inner tube 2 runs through the balloon body 1; the inner tube 2 is located symmetrically on the balloon body 1 On the axis; electrodes are arranged on the inner tube 2; the balloon body includes an insulating layer 11 and a balloon wall 12 from the outside to the inside; the thickness of the balloon wall is 20 μm, and the thickness of the insulating layer is 3 μm; The material of the balloon wall is polyethyleneimine, and the material of the insulating layer is polytetrafluoroethylene.

Embodiment 2

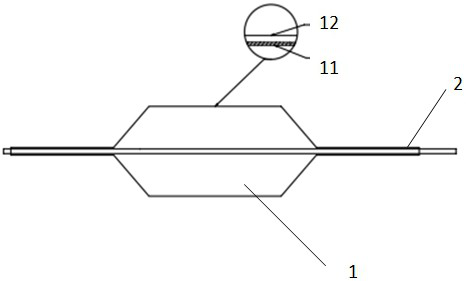

[0060] Such as figure 1 As shown, the present embodiment provides a pulse balloon, which includes a balloon body 1 and an inner tube 2; the inner tube 2 runs through the balloon body 1; the inner tube 2 is located symmetrically on the balloon body 1 on the shaft; electrodes are arranged on the inner tube 2; the balloon body includes an insulating layer 11 and a balloon wall 12 from the outside to the inside; the balloon body 1 is prepared by spraying; the balloon wall The thickness is 15 μm, and the thickness of the insulating layer is 4 μm; the material of the balloon wall is polyethyleneimine, and the material of the insulating layer is polytetrafluoroethylene.

[0061] The spraying includes: after the balloon wall is blow-molded, the polytetrafluoroethylene dispersion is sprayed on the outer surface of the balloon wall, and dried at 190°C. When the balloon pressure reaches 14ATM, set the pulse voltage at 5000V and 1HZ to start discharging 100 times. After repeating 5 times...

Embodiment 3

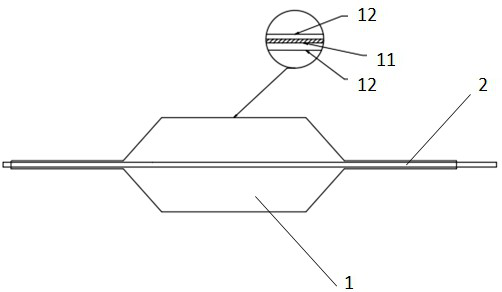

[0063] Such as figure 1 As shown, the present embodiment provides a pulse balloon, which includes a balloon body 1 and an inner tube 2; the inner tube 2 runs through the balloon body 1; the inner tube 2 is located symmetrically on the balloon body 1 on the shaft; the inner tube 2 is provided with electrodes; the balloon body includes an insulating layer 11 and a balloon wall 12 from the outside to the inside; the balloon body 1 is prepared by blow molding; the balloon The thickness of the wall is 25 μm, and the thickness of the insulating layer is 2 μm; the material of the balloon wall is polyethyleneimine, and the material of the insulating layer is polytetrafluoroethylene.

[0064] The package blow molding includes: putting the PTFE film on the outer layer of the balloon tube, putting it into the mold of the balloon molding machine, and performing blow molding. The process parameters of the blow molding are: the blow molding temperature is 140°C, heating The time is 15s, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com