A kind of high foaming ratio pla/pbat/talc composite foaming oil-absorbing material and preparation method thereof

A technology for composite foaming and oil-absorbing materials, applied in the field of environmental protection, can solve the problems of inability to use oil-stained adsorption materials, incapable of oil-stained adsorption treatment, low mechanical strength of film materials, etc., so as to avoid cavitation effect, improve nucleation rate, The effect of increasing the aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

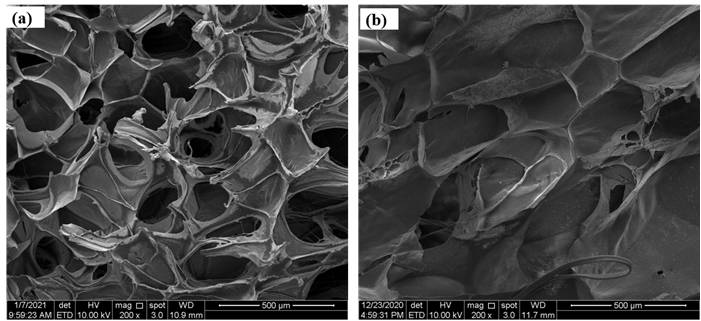

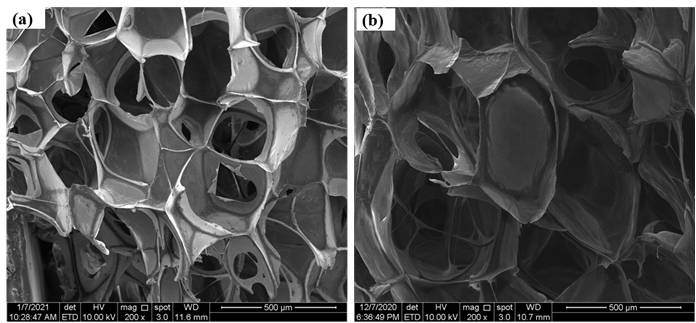

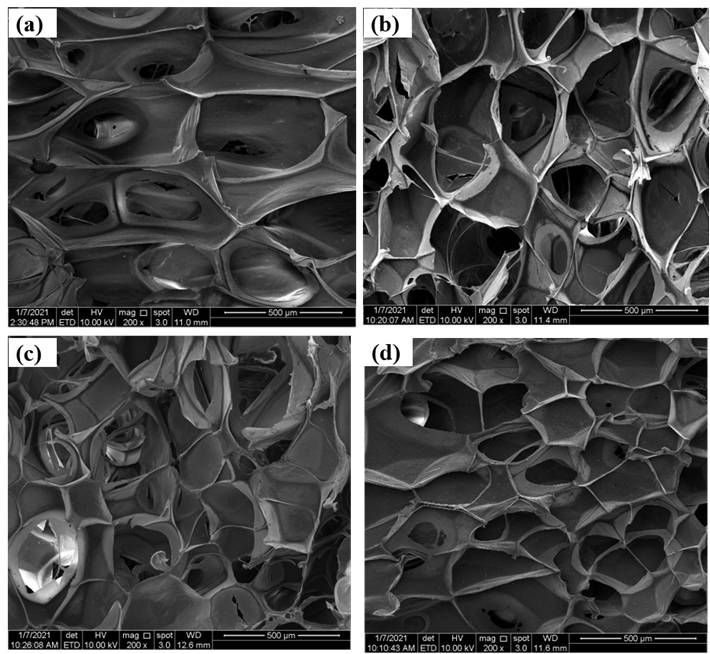

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation method of PLA / PBAT / Talc composite foaming oil-absorbing material

[0037] The preparation method of PLA / PBAT / Talc composite foaming oil-absorbing material, comprising the following steps:

[0038] (1) PLA, PBAT and Talc are melted and blended to make a sheet

[0039] 65wt% PLA (number average molecular weight 50000), 30wt% PBAT, 3wt% talc, 0.5wt% antioxidant 1010, 0.5wt% lubricant polytetrafluoroethylene, 1.0wt% anti-hydrolysis agent Bio Adimide 100 was melt-blended and pelletized on a twin-screw extruder to obtain PLA / PBAT / Talc blended granules; the PLA / PBAT / Talc blended granules were placed on a vacuum hot press, and the temperature and pressure were 160 The PLA / PBAT / Talc blended particles were hot-pressed for 5 min under the conditions of ℃ and 1200 psi to prepare thin plates with length, width and height of 300 mm, 200 mm and 1 mm respectively.

[0040] (2) High temperature heat treatment before saturation treatment

[0041] The thin...

Embodiment 2

[0050] Example 2: Effect of high temperature heat treatment before saturation on the properties of PLA / PBAT / Talc composite foamed oil-absorbing material

[0051] 1. Specimen Preparation

[0052] Sample 1: The PLA / PBAT / Talc composite foamed oil-absorbing material prepared with reference to the method steps (1) to (6) described in Example 1 is designated as sample 1, wherein the high temperature heat treatment in step (2) The temperature is set to 180 °C.

[0053] Control sample 1: refer to the PLA / PBAT / Talc composite foamed oil-absorbing material prepared by steps (1), steps (3) to (6) in Example 1, and denoted as control sample 1.

[0054] The difference between the control sample 1 and the sample 1 in the preparation process is only that the control sample 1 has not undergone the high-temperature heat treatment process before step (2) in Example 1 is saturated.

[0055] 2. Performance test

[0056] The performance test indicators of PLA / PBAT / Talc composite foamed oil-absor...

Embodiment 3

[0078] Example 3: Effects of ultrasonic treatment at different stages on the properties of PLA / PBAT / Talc composite foam materials

[0079] 1. Specimen Preparation

[0080] 1) Sample 2

[0081] 73wt% PLA (number average molecular weight 50000), 20wt% PBAT, 5wt% talc, 0.5wt% antioxidant 1010, 1.0wt% lubricant polytetrafluoroethylene, 0.5wt% anti-hydrolysis agent Bio Adimide 100 was used as a raw material, and a PLA / PBAT / Talc composite foaming oil-absorbing material sample was prepared with reference to steps (1) and steps (4) to (6) in Example 1, which was designated as sample 2. The difference from Embodiment 1 is the relevant parameter settings in steps (2) and (3):

[0082] Step (2) High temperature heat treatment before saturation treatment

[0083] The thin plate is placed in the mold cavity of the supercritical fluid reactor, the temperature in the mold cavity of the reactor is heated to 130 °C, and the supercritical CO is introduced after the temperature is constant. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com