Fluorine-silicon modified styrene-acrylic emulsion with comb-shaped structure and preparation method of fluorine-silicon modified styrene-acrylic emulsion

A technology of fluorosilicon modification and styrene-acrylic emulsion, which is applied in the direction of coating, etc., can solve the problems of slow polymerization rate, product stability and unsatisfactory surface properties, etc., and the realization time is short, the preparation process is simple and easy, and the stability is good and the effect of surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

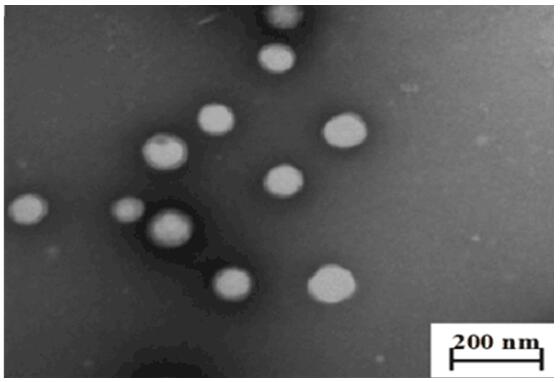

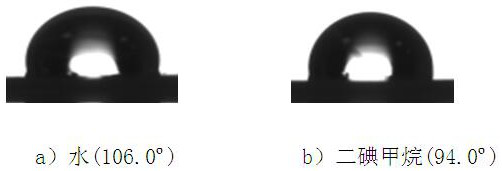

Image

Examples

Embodiment 1

[0031] 1) Dissolve 1g sodium lauryl sulfate and 2g sodium alcohol ether sulfosuccinate containing double bonds in 90g water to prepare emulsifier aqueous solution A;

[0032] 2) A monomer mixture of 10g styrene, 10g butyl acrylate, 7g dodecafluoroheptyl acrylate, 0.5g γ-methacryloxypropyltrimethoxysilane and 4.85g hydroxyl silicone oil was mixed with 1g n-hexadecane Prepare a uniform solution B;

[0033] 3) Disperse solution B into emulsifier aqueous solution A under stirring to obtain pre-emulsion C; 4) Ultrasonicate pre-emulsion C in an ultrasonic cell pulverizer with a power of 600w for 15 min. Obtain miniemulsion D;

[0034] 5) Add 0.3g of water-soluble initiator azobisisobutylamidine hydrochloride to 15g of water to make initiator aqueous solution E

[0035] 6) Raise the temperature of the miniemulsion D to 80°C, drop the aqueous initiator solution E into the miniemulsion D for 2 hours to initiate polymerization, and keep the reaction for 6 hours after the initiator is ...

Embodiment 2

[0037] 1) Mix 0.5g sodium dodecylsulfate, 0.5g sodium dodecylbenzenesulfonate and 2g allyl-containing special alcohol ether sulfate in 100g water to make emulsifier aqueous solution A;

[0038] 2) A monomer mixture of 10g styrene, 5g butyl acrylate, 5g methyl methacrylate, 7g hexafluorobutyl acrylate, 0.5g γ-methacryloxypropyl trimethoxysilane and 4.85g hydroxyl silicone oil Prepare a uniform solution B with 1.5g n-hexadecane;

[0039] 3) Disperse solution B into emulsifier aqueous solution A under stirring to obtain pre-emulsion C; 4) Ultrasonicate pre-emulsion C in an ultrasonic cell pulverizer with a power of 500w for 20min. Obtain miniemulsion D;

[0040] 5) Add 0.3g of water-soluble initiator azobisisobutylamidine hydrochloride to 10g of water to make initiator aqueous solution E

[0041] 6) Raise the temperature of the miniemulsion D to 85°C, drop the aqueous initiator solution E into the miniemulsion D for 2 hours to initiate polymerization, and keep it warm for 5 hou...

Embodiment 3

[0043] 1) Dissolve 1.5g sodium dodecylbenzenesulfonate and 2g sodium alcohol ether sulfosuccinate containing double bonds in 90g water to prepare emulsifier aqueous solution A;

[0044] 2) A monomer mixture of 5g styrene, 5g methyl methacrylate, 10g butyl acrylate, 7g dodecafluoroheptyl acrylate, 0.5g vinyltriethoxysilane and 5g hydroxyl silicone oil was mixed with 1.5g n-hexadecane Alkane is prepared into a uniform solution B;

[0045] 3) Disperse solution B into emulsifier aqueous solution A under stirring to obtain pre-emulsion C; 4) Ultrasonicate pre-emulsion C in an ultrasonic cell pulverizer with a power of 600w for 15 min. Obtain miniemulsion D;

[0046] 5) Add 0.3g of water-soluble initiator ammonium persulfate to 15g of water to make initiator aqueous solution E

[0047] 6) Raise the temperature of the miniemulsion D to 85°C, drop the aqueous initiator solution E into the miniemulsion D for 1.5h to initiate polymerization, and keep the reaction for 5h after the init...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com