Preparation method of ferrocenecarboxylic acid

A technology of ferrocene formic acid and toluene, applied in chemical instruments and methods, metallocenes, mixers with rotary stirring devices, etc., can solve problems such as oxidation of reactants, and achieve the effects of reducing the generation of impurities and improving the feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of ferrocenecarboxylic acid, comprising the following steps:

[0039] 1) Adding process: add toluene to the reaction kettle one by one, start stirring, add ferrocene and toluene, then vacuumize, continue stirring and pass cooling water to adjust the internal temperature to 15°C, then pass carbon dioxide gas for 30 minutes;

[0040] 2) Synthesis process: add anhydrous AlCl to the aforementioned reaction kettle 3 And continue to feed carbon dioxide gas, keep the internal temperature at 21 ℃, keep warm for 6 hours;

[0041] 3) Hydrolysis process: Add a part of crushed ice and deionized water into the hydrolysis kettle, then carefully transfer the above reaction mixture to the hydrolysis kettle for 30 minutes, use nitrogen isolation during the period, continue to add crushed ice to maintain the internal temperature of the hydrolysis Below 30°C, continue to stir for 2 hours to ensure complete hydrolysis;

[0042] 4) Filtration and water washing process: ...

Embodiment 2

[0047] A preparation method of ferrocenecarboxylic acid, comprising the following steps:

[0048] 1) Adding process: Add toluene to the reaction kettle one by one, start stirring, add ferrocene and toluene, then vacuumize, continue stirring and pass cooling water to adjust the internal temperature to 18°C, then pass carbon dioxide gas for 40 minutes;

[0049] 2) Synthesis process: add anhydrous AlCl to the aforementioned reaction kettle 3 And continue to feed carbon dioxide gas, keep the internal temperature at 23°C, and keep warm for 8 hours;

[0050] 3) Hydrolysis process: add a part of crushed ice and deionized water to the hydrolysis kettle, then carefully transfer the above reaction mixture to the hydrolysis kettle for 60 minutes, use nitrogen isolation during the period, continue to put crushed ice into it, and maintain the internal temperature of the hydrolysis Below 30°C, continue to stir for 3 hours to ensure complete hydrolysis;

[0051] 4) Filtration and water was...

Embodiment 3

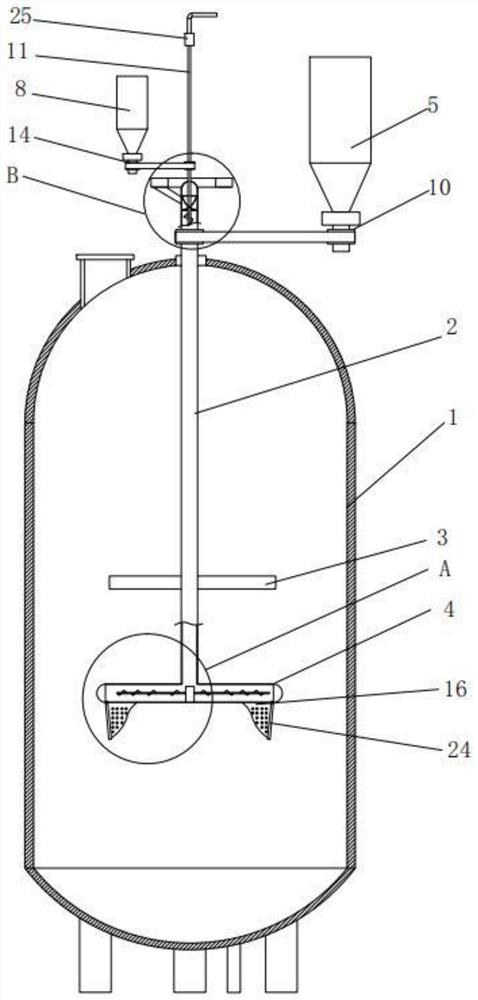

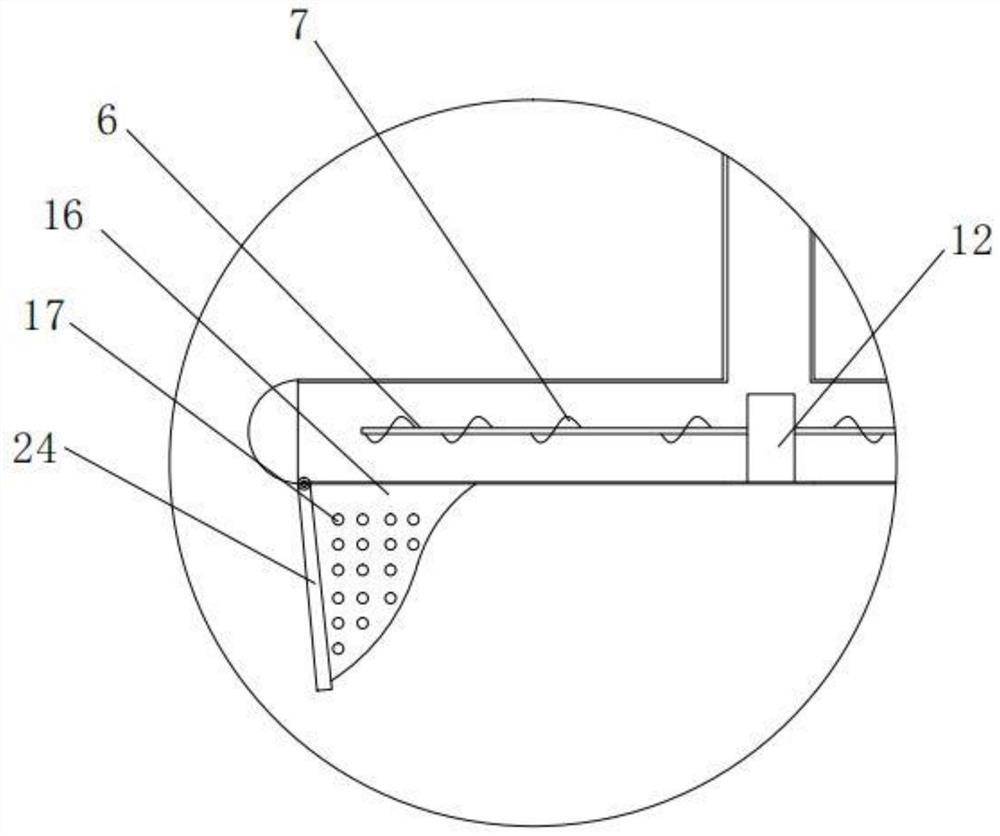

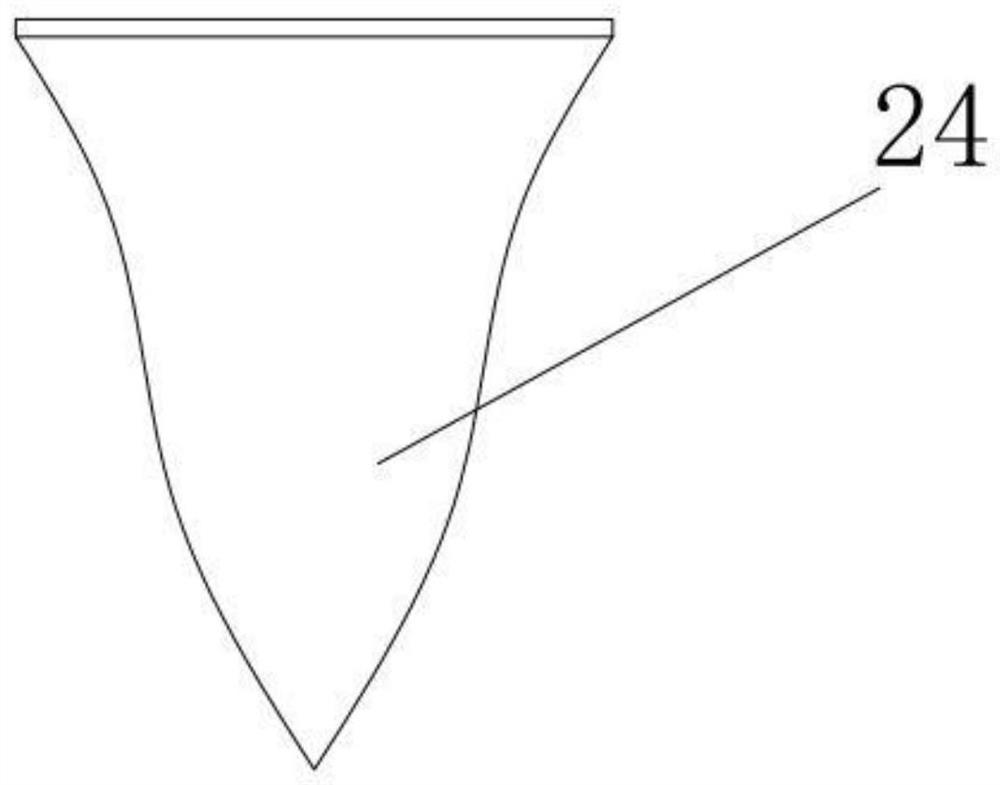

[0056] Such as figure 1 , figure 2 with image 3 As shown, the hydrolysis kettle of the present invention includes a kettle body 1, a hollow stirring rod 2 is installed in the kettle body, a first stirring blade 3 is installed in the middle of the stirring rod, and a hollow stirring rod is installed at the bottom of the stirring rod. The horizontal bar 4 is used to drop crushed ice on the horizontal bar; the first driving motor 5 is installed in the center of the horizontal bar, and a pair of stirring rollers 6 arranged horizontally are respectively installed on the left and right sides of the driving motor to stir The stick is equipped with a first helical blade 7, and the first helical blades on both sides are configured to drive the crushed ice to move outward when rotating; the top of the stirring rod passes through the hydrolysis tank, and the top side of the stirring rod is equipped with The second driving motor 8, the first driven wheel 9 is housed on the described s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com