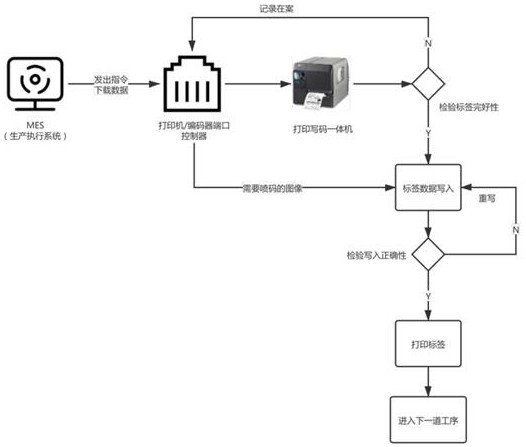

Labeling and coding production process of intelligent label

A smart label and production process technology, applied in the printing process, collaborative operation device, printing, etc., can solve the problems of low efficiency of water-washed labels and high cost of resin-based carbon ribbons, and achieve more added value, high efficiency, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0034] In the foreseeable future, the printing content of clothing washing labels may gradually decrease, leaving only the clothing brand LOGO and QR code. A different type of clothing will produce a different QR code, which is difficult to achieve from the traditional flexo printing theory. In order to follow this trend, a digital printing module (jet printer) is added to the flexographic printing machine for printing of personalized customization or variable data (such as barcode, two-dimensional code). This enabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com