Anti-deformation glass drilling and chamfering grinding tool

A technology of anti-deformation and chamfering, which is applied in the direction of grinding machines, manufacturing tools, and parts of grinding machine tools, and can solve problems such as loss of shape and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

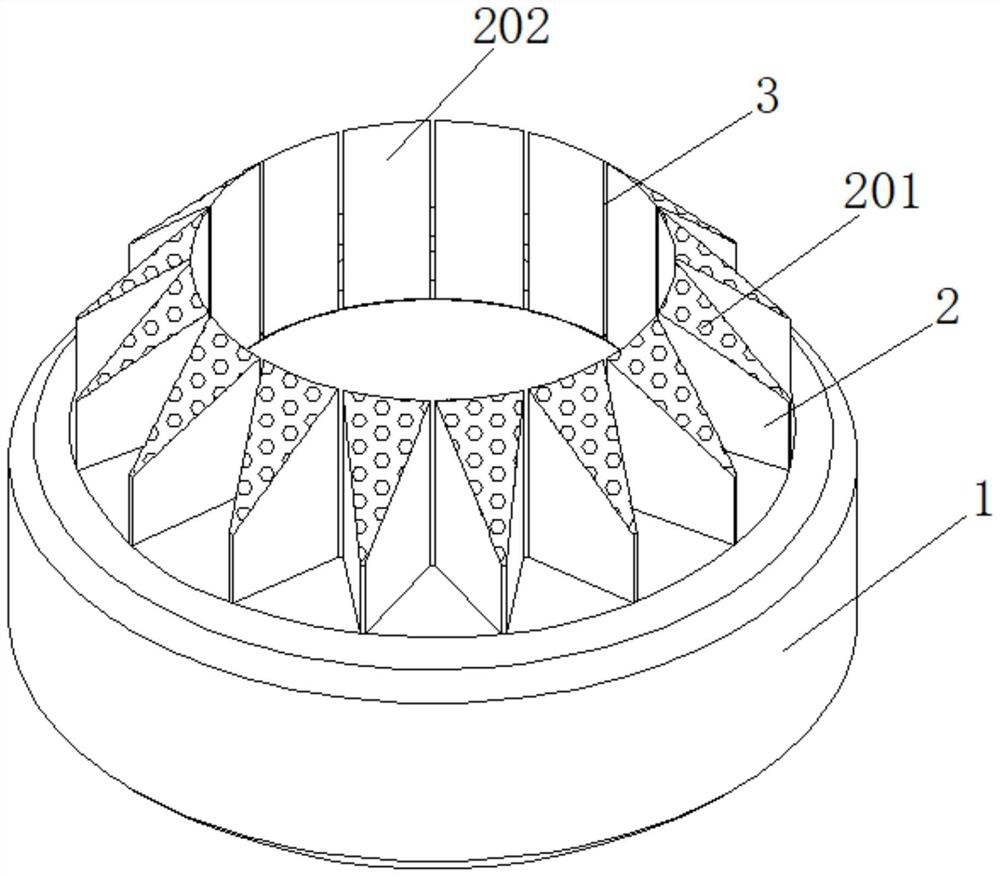

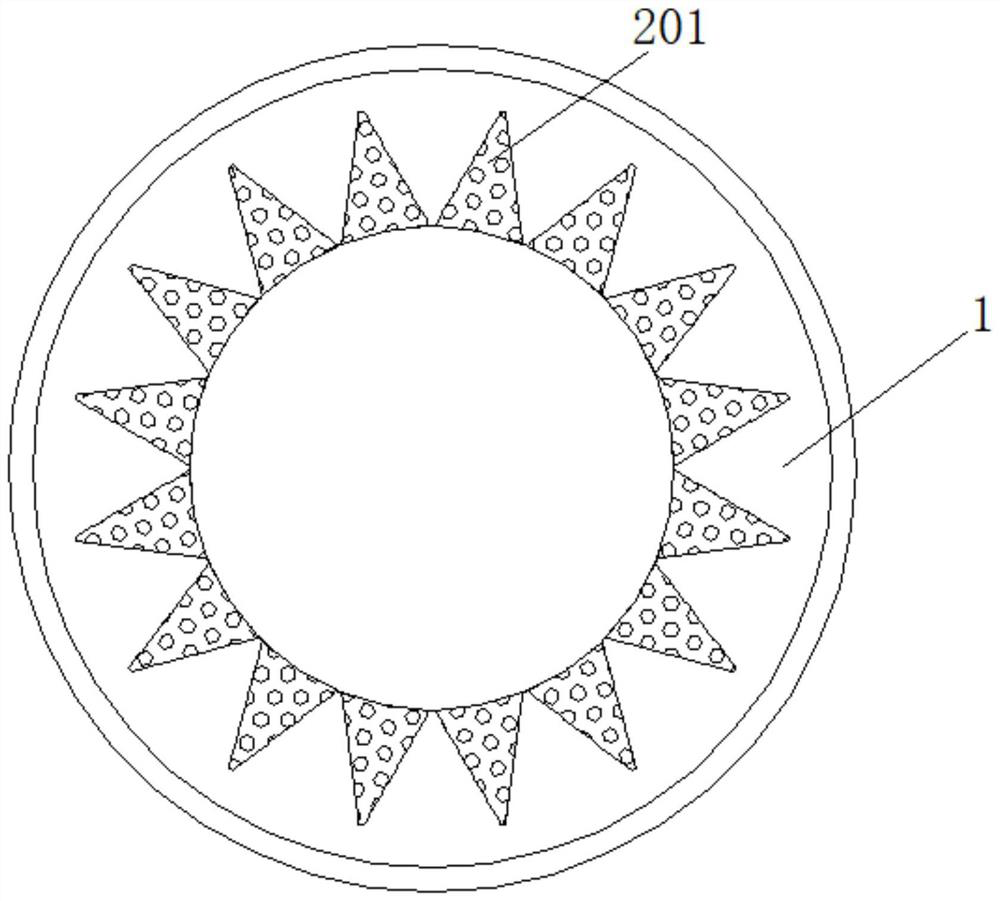

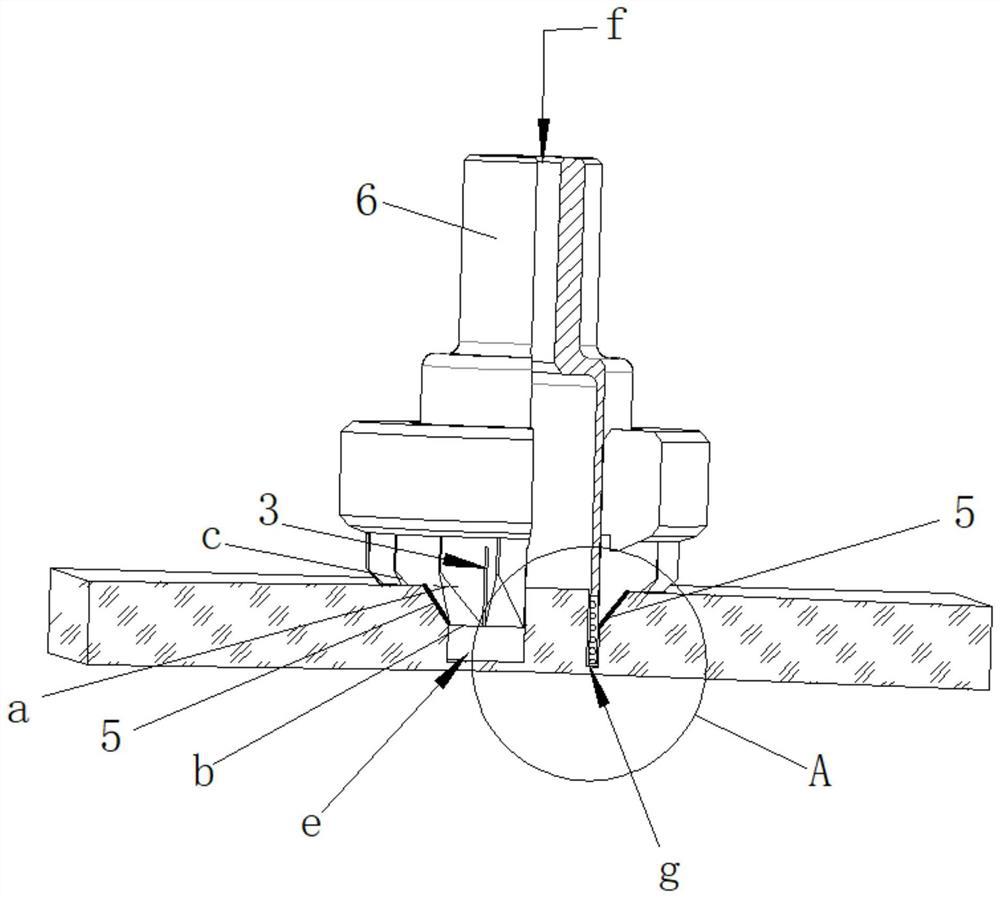

[0035] Embodiment 1: as Figure 1-2 As shown, an anti-deformation glass drilling and chamfering abrasive tool includes a base 1 and a serrated ring for glass chamfering, the serrated ring includes a plurality of chamfering grinding teeth 2; the base 1 is a ring Block-shaped, a plurality of chamfering grinding teeth 2 are arranged circumferentially on the end surface of the base 1, the end surface of the chamfering grinding teeth 2 away from the base 1 is the working surface 201, adjacent to the The gap between the chamfering grinding teeth 2 forms a water tank 3 for passing water.

[0036] In the above embodiment, the serrated ring is formed by a plurality of independent chamfering grinding teeth, which replaces the existing chamfering grinding tool with integral continuous grinding surface. The serrated ring of the present invention has anti- The deformation function solves the problem of loss of shape and failure; multiple water tanks formed between multiple chamfering grin...

Embodiment 2

[0038] Such as Figure 1-2 As shown, the chamfering grinding teeth 2 are wedge-shaped, each of the chamfering grinding teeth 2 is close to the center of the base 1, and the vertical inner wall 202 of the chamfering grinding teeth 2 faces inward, each of the chamfering grinding teeth 2 The chamfering grinding teeth 2 circle around the central axis of the base 1 to form a closed-loop zigzag ring.

[0039] In the above embodiment, when each chamfering grinding tooth 2 is arranged around the central axis of the base 1, a closed-loop zigzag ring can be formed to obtain a circular chamfering working surface; independent chamfering grinding teeth 2 can be formed according to The actual chamfering needs to be arranged into zigzag rings of different specifications.

Embodiment 3

[0041] Such as Figure 1-2As shown, the working surface 201 of each chamfering grinding tooth 2 is inclined from the inside to the outside in a direction close to the outside of the base 1 , forming an annular inclined surface.

[0042] Specifically, the working surface 201 is plated with diamond.

[0043] In the above-mentioned embodiment, the working surface 201 of each chamfering grinding tooth 2 surrounds the annular inclined working surface, which not only realizes the function of chamfering, but also has the effect of anti-deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com